Square yeeb nkab

Cov duab:

Ntug Hollows: Square, Rectangular, Round, Daim duab peb sab, Hexagonal, Eliptical Hollow seem

Scaffolding

Kev siv:

Hollow Sections:

Kev tsim kho: Hall Structure, Hiav Txwv Trestle, Airport Structure, Shipbuilding, Security Door Frames, Garage Doors, Strengthening Liners of Steel Doors and Windows, Indoor Partition Walls, Cable Bridge Structures and Expressway Safety Guards, Balustrade, Decorating, Residential, Ornamental Pipes

Automotive Parts: Motorcar Case, Tsheb thiab Bus Manufacture, Tsheb

Kev Ua Liaj Ua Teb: Agricultural Equipment

Kev lag luam: Machinery, Hnub Ci Stent, Offshore Roj Field, Mine Equipment, Electromechanical Hardware,, heavy engineering, Mining thiab Resources, Process Engineering, Materials Handling, Mechanical Parts

Tsheb thauj mus los: Taug kev Rails, Roll-up Qhov Rooj, Guardrail, Plaza Structure, Signage, Road Fencing, Fencing

Logistics Cia: Lub khw muag khoom loj, cov thawv ntim khoom, kev lag luam thauj mus los, kev tsim khoom lag luam

Lwm yam: Cov cuab yeej ua kis las, khoom siv ua si, rooj tog zaum, rooj tog hauv tsev kawm ntawv

Scaffolding Tube:

Cov Khoom Siv Cia Racks, Pallets, Hydraulic Platforms, Trusses, Kem, Purlins, Tsev cog khoom Stands Towers

Txuj Txuj Ci:

Hollow Sections:

GB / T 13793 Longitudinal hluav taws xob tsis kam welded steel hlab

GB / T 6728 Txias tsim steel hollow seem rau cov qauv dav dav-Dimensions, cov duab, qhov hnyav thiab kev tso cai sib txawv

ASTM A500 Cold Formed Welded thiab Seamless Carbon Steel Steel Structure Tubing nyob rau hauv Round thiab Shapes

ASTM A 53 Txuj Specification rau Yeeb Nkab, Hlau, Dub thiab Kub-dipped, Zinc-Coated, Welded thiab Seamless

TS EN 10210 Kub ua tiav cov qauv hollow seem ntawm cov hlau tsis muaj hlau thiab nplua nplej hlau

TS EN 10219 Txias tsim welded structural hollow seem ntawm cov hlau tsis muaj hlau thiab nplua nplej

JIS G 3466 Carbon steel Square rau lub hom phiaj dav dav

BS 1387 Steel Tubes siv rau Dej, Roj, Cua thiab Chav

TS EN 6323 PART5 SEAMLESS AND WELDED STEEL TUBES RAU AUTOMOBILE MECHANICAL THIAB GENERAL ENGINEER PURPOSE

IS: 1161 Steel Tubes Rau Lub Hom Phiaj thiab Hluav Taws Xob.

IS: 3601 Steel tubes rau cov khoom siv kho tshuab & dav dav engineering.

IS: 3074 Steel tubes rau tsheb lub hom phiaj.

IS: 4923 Steel tubes rau Hollow seem siv hauv cov qauv

DIN 1626 WELDED Circular Tubes ntawm cov hlau tsis muaj hlau nrog

TXOJ CAI ZOO TSHAJ PLAWS

DIN 2394 WELDED THIAB SIZE PreCISION STEEL TUBES

Scaffolding Tube:

GB 15831 Steel Tube Scaffold Couplers

TS EN 39 Cov hlua khi hlua khi rau cov raj thiab cov hlua txuas txuas

BS 1139 Hlau scaffolding

Steel Qib:

GB/T 13793, GB/T 6728, GB 15831:

Q195, Q215, Q235, Q275, Q295, Q345, 08F, 08, 08AL, 08F, 10F, 10, HG5, DF08

EN 10210, EN 10219, BS 1387: S185, S235, S235JR, S235 G2H, S275, S275JR, S355JRH, S355J2H, St12, St13, St14, St324, St3

ASTM A500, ASTM A53: Gr.A, Gr B, Gr C, Gr.D, DC01, DC03, 1008, 1010

JIS G 3466: SS330, SS440, SS490, SPHD, SPHE

Txheej Txheem: ERW thiab Seamless

Loj:

Hollow Sections:

Square: 10mmx10mm - 500mmx500mm

Retangular: 10mm x 20mm - 600mmx400mm

Loj: 1/8 "- 4"

Phab ntsa Thickness: 0.5-20.0mm

Ntev: 0.3 mtr - 18 mtr raws li cov neeg siv khoom xav tau

Scaffolding Tube:

Sab nraud txoj kab uas hla: 38mm, 42mm, 48.3mm-48.6mm

Phab ntsa Thickness: 2.0mm, 2.5mm, 2.75mm, 3.0mm, 3.25mm, 3.85mm, 4.0mm

Ntev: 0.3m-18mtr

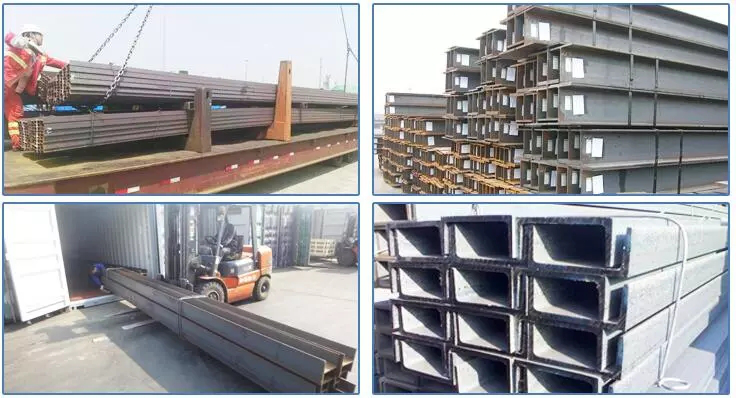

Txheej txheem:

Seamless: Kub Rolled, Kub Tshawb Nrhiav

Welded: ERW, HFW

Txheej: Kub-dipped Galvanized, Hluav taws xob Galvanized

Raw Khoom:

Seamless: Yeeb Nkab Billet ( Kub Rolled, los yog Con-casting), Niam Yeeb Nkab

Welded: Kub Rolled Steel Chev (HRC), Cold Rolled Steel Chev (CRC), Pre-pained Galvanized Steel Sawb

Xaus: Square txiav, Burr tshem tawm

Nto: Lightly oiled, Kub dip galvanized, Electro galvanized, Dub

Kev kho cua sov: Bright Annealed, Dub Annealed

Ntim: Yas ntsaws rau hauv ob qho kawg, Hexagonal bundles ntawm max.2,000kg nrog ob peb lub strips, Ob lub cim npe ntawm txhua lub nras, qhwv hauv cov ntawv tsis muaj dej, PVC lub tes tsho, thiab sackcloth nrog ntau lub strips

Kev Xeem: Tshuaj ntsuam xyuas Chemical Component, Mechanical Properties (Qhov kawg tensile zog, tawm los

Lub zog, Elongation), Cov Khoom Siv Hluav Taws Xob (Flattening Test, Flaring Test, Bending Test, Hardness Test, Blow Test, Impact Test thiab lwm yam), Kev tshuaj xyuas sab nrauv

Mill Test Certificate: EN 10204/3.1B

Square tubes qhov ntau thiab tsawg

| Loj (mm) | Phab ntsa Thickness (mm) | Loj (mm) | Phab ntsa Thickness (mm) |

| 20 * 20 | 1.2 | 70 * 70 60 * 80 100 * 40 | 1.8 |

| 1.3 | 2 | ||

| 1.4-1.5 Nws | 2.2 | ||

| 1.7 | 2.3 | ||

| 1.8 | 2.5-4.0 Nws | ||

| 2 | 4.5-5.0 Nws | ||

| 2.2 | 5.5-5.75 Nws | ||

| 2.3 | 75 * 75 60 * 90 100 * 50 | 1.8 | |

| 2.5-2.75 Nws | 2 | ||

| 25 * 25 20 * 30 | 1.2 | 2.2 | |

| 1.3 | 2.3 | ||

| 1.5 | 2.5-4.0 Nws | ||

| 1.7 | 4.5-5.0 Nws | ||

| 1.8 | 5.5-5.75 Nws | ||

| 2 | 80 * 80 100 * 60 100 * 80 120 * 60 | 2 | |

| 2.3-2.3 | 2.2 | ||

| 2.5-3.0 Nws | 2.3 | ||

| 30 * 30 30 * 40 25 * 40 20 * 40 | 1 | 2.5-4.0 Nws | |

| 1.2 | 4.5-5.0 Nws | ||

| 1.3 | 5.5-5.75 Nws | ||

| 1.5 | 7.5-7.75 Nws | ||

| 1.7 | 100 * 100 hli 120 * 80 | 2 | |

| 1.8 | 2.2 | ||

| 2 | 2.3 | ||

| 2.2 | 2.5-5.0 Nws | ||

| 2.3 | 5.5-5.75 Nws | ||

| 2.5 * 2.75 hli | 7.5-7.75 Nws | ||

| 3 | 120 * 120 hli 140 * 80 150 * 100 hli 160 * 80 | 2.5 | |

| 40 * 40 30 * 50 25 * 50 | 1.2 | 2.75 ib | |

| 1.3 | 3 | ||

| 1.4-1.5 Nws | 3.25-5.0 Nws | ||

| 1.7 | 5.5-7.0 Nws | ||

| 1.8 | 7.5-7.75 Nws | ||

| 2 | 140 * 140 hli 150 * 150 hli 200 * 100 hli | 3.5-4.0 Nws | |

| 2.2-2.3 | 4.5-5.0 Nws | ||

| 2.5-4.0 Nws | 5.25-7.0 Nws | ||

| 50 * 50 60 * 40 30 * 60 40 * 50 | 1.5 | 7.5-7.75 Nws | |

| 1.7 | 160 * 160 hli 180 * 180 hli

| 3 | |

| 1.8 | 3.5 | ||

| 2 | 3.75 ib | ||

| 2.2 | 4.0-5.0 | ||

| 2.3 | 5.25-5.75 Nws | ||

| 2.5 * 4.0 | 7.5-7.75 Nws | ||

| 4.25-5.0 Nws | 60 * 60 40 * 80 75 * 75 50 * 70 50 * 80 | 2.3 | |

| 60 * 60 40 * 80 75 * 45 50 * 70 50 * 80 | 1.5 | 2.5-4.0 Nws | |

| 1.7 | 4.25-5.0 Nws | ||

| 1.8 | 5.5-5.75 Nws | ||

| 2 | / | ||

| 2.2-2.3 | / |

Muaj Cov Qauv Zoo

ASTM A500 Cold Formed Welded thiab Seamless Carbon Steel Steel Structure Tubing nyob rau hauv Round thiab Shapes

TS EN 10210 Kub ua tiav cov qauv hollow seem ntawm cov hlau tsis muaj hlau thiab nplua nplej hlau

TS EN 10219 Txias tsim welded structural hollow seem ntawm cov hlau tsis muaj hlau thiab nplua nplej

ASTM A53 siv los ua cov qauv hlau lossis cov kav dej tsis tshua muaj siab

Standard Corner Radius (Structural Size:)

Max.3 x Nominal Phab Ntsa Thickness

| Mechanical Sizes | Tus Qauv Loj | ||

| Loj tshaj Nominal Sab Nraud Dimension | Sab Nraud Tolerance ntawm txhua sab ntawm kaum | Loj tshaj Nominal Sab Nraud Dimension | Sab Nraud Tolerance ntawm txhua sab ntawm kaum |

| 3/16 – 5/8 | ± 0.004 | 2 1/2 thiab qis dua | ± 0.020 |

| 5/8 txog 1 1/8 | ± 0.005 | tshaj 2 1/2 rau 3 1/2 | ± 0.020 |

| tshaj 1 1/8 rau 1 1/2 | ± 0.006 | 3 1/2 txog 5 1/2 | ± 0.030 |

| tshaj 1 1/2 rau 2 | ± 0.008 | ntau tshaj 5 1/2 | ± 1% |

| ua 2to3 | ± 0.010 | ||

| ntau 3a4 | ± 0.020 | ||

| ua 4a6 | ± 0.020 | ||

| ua 6a8 | ± 0.025 | ||

Kev ncaj

Mechanical Size: Max.1/16 "hauv 3 feet

Tus Qauv Loj: Max.1/8 "x Tus naj npawb ntawm ko taw ntawm tag nrho qhov ntev muab faib los ntawm 5

Phab ntsa Thickness

Mechanical & Structural Sizes: ± 10% ntawm Nominal Phab Ntsa Thickness

Squareness ntawm Sab

Mechanical Size: Max: ± b = cx 0.006 "

b = Tolerance for out-of-square

c = Qhov loj tshaj sab nraud ntawm cov tiaj tiaj

Structure Sizes: Cov sab uas nyob ib sab tuaj yeem sib txawv ntawm 90 ° los ntawm ± 2 °

Maximum Twist (Mechanical & Structure Sizes)

| Loj tshaj plaws Dimension, nti | Max.Twist *, ntiv tes |

| tshaj 1/2 rau 1 1/2 | 0.050 Nws |

| tshaj 1 1/2 rau 2 1/2 | 0.062 ib |

| tshaj 2 1/2 rau 4 | 0.075 ib |

| ua 4a6 | 0.087 ib |

| ua 4a8 | 0.100 Nws |

Convexity & Concavity (Mechanical & Structural Sizes)

| Loj tshaj nominal OD, nti | Kev kam rau siab ± Inches |

| 2 1/2 thiab qis dua | ± 0.010 |

| tshaj 2 1/2 rau 4 | ± 0.015 |

| ua 4a8 | ± 0.025 |

Cov Qauv Tubing A 500 Yuav Tsum Tau

| Qib | Tshuaj | Lub cev | ||||||

| C Max.% | Mn Max.% | P Max.% | S Max.% | Cu Max.% | Tensile zog, min.psi | Yield zog, min.psi | Elongation hauv 2 hauv. | |

| Qib B | 0.26 | / | 0.04 ib | 0.05 Nws | 0.20 ib | 58,000 ib | 46,000 ib | 23 |

| Qib C | 0.23 | 1.35 Nws | 0.04 ib | 0.05 Nws | 0.20 ib | 62,000 ib | 50,000 | 21 |

Bright Annealed, Dub Annealed

Yas plugs nyob rau hauv ob qhov kawg, Hexagonal bundles ntawm max.2,000kg nrog ob peb lub strips, Ob lub cim npe ntawm txhua lub nras, qhwv hauv cov ntawv tsis muaj dej, PVC lub tes tsho, thiab sackcloth nrog ntau lub strips

Kev tshuaj ntsuam xyuas: Chemical Component Analysis, Mechanical Properties