Square Pipe

Shape:

Hollow Sections: Square, Rectangular, Round, Triangular, Hexagonal, Eliptical Hollow sections

Scaffolding

Usage:

Hollow Sections:

Construction: Hall Structure, Sea Trestle, Airport Structure, Shipbuilding, Security Door Frames, Garage Doors, Strengthening Liners of Steel Doors and Windows, Indoor Partition Walls, Cable Bridge Structures and Expressway Safety Guards, Balustrade, Decorating, Residential, Ornamental Pipes

Automotive Parts:Motorcar Case,Car and Bus Manufacture, Vehicles

Agriculture: Agricultural Equipment

Industry:Machinery,Solar Stent, Offshore Oil Field, Mine Equipment, Electromechanical Hardware, , heavy engineering, Mining and Resources, Process Engineering, Materials Handling,Mechanical Parts

Traffic:Walking Rails, Roll-up Doors, Guardrail, Plaza Structure, Signage, Road Furniture, Fencing

Logistics Storage: Supermarket Shelves, Containers, Transport Industries, Commercial Construction

Other: Sports Apparatus, Leisure Equipment, Furniture, School Furniture

Scaffolding Tube:

Material Storage Racks, Pallets, Hydraulic Platforms, Trusses, Columns, Purlins, Greenhouse Stands Towers

Quality Standard:

Hollow Sections:

GB/T 13793 Longitudinal electric resistance welded steel tubes

GB/T 6728 Cold formed steel hollow sections for general structure–Dimensions,shapes,weight and permissble deviations

ASTM A500 Cold Formed Welded and Seamless Carbon Steel Steel Structural Tubing in Round and Shapes

ASTM A 53 Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless

EN 10210 Hot finished structural hollow sections of non-alloy and fine grain structural steels

EN 10219 Cold formed welded structural hollow sections of non-alloy and fine grain steels

JIS G 3466 Carbon steel Square for general structural purposes

BS 1387 Steel Tubes for use for Water, Gas, Air and Steam

BS 6323 PART5 SEAMLESS AND WELDED STEEL TUBES FOR AUTOMOBILE MECHANICAL AND GENERAL ENGINEER PURPOSE

IS : 1161 Steel Tubes For Structural purpose and Electric poles.

IS : 3601 Steel tubes for mechanical & general engineering purposes.

IS : 3074 Steel tubes for Automobile purpose.

IS : 4923 Steel tubes for Hollow sections used in structures

DIN 1626 WELDED CIRCULAR TUBES OF NON ALLOY STEELS WITH

SPECIAL QUALITY EQUIREMENTS

DIN 2394 WELDED AND SIZED PRECISION STEEL TUBES

Scaffolding Tube:

GB 15831 Steel tube scaffold couplers

EN 39 Loose steel tubes for tube and coupler scaffolds

BS 1139 Metal scaffolding

Steel Grade:

GB/T 13793, GB/T 6728, GB 15831:

Q195, Q215, Q235, Q275, Q295, Q345, 08F, 08, 08AL, 08F, 10F, 10, HG5, DF08

EN 10210, EN 10219, BS 1387: S185, S235, S235JR, S235 G2H, S275, S275JR, S355JRH, S355J2H, St12, St13, St14, St33, St37, St44,ST52

ASTM A500, ASTM A 53: Gr. A, Gr B, Gr C, Gr.D, DC01, DC03, 1008, 1010

JIS G 3466: SS330, SS440, SS490, SPHD, SPHE

Process: ERW and Seamless

Size:

Hollow Sections:

Square:10 mmx10mm – 500 mmx500mm

Retangular:10mm x 20mm – 600mmx400mm

Round: 1/8″ – 4″

Wall Thickness: 0.5 – 20.0mm

Length:0.3 mtr – 18 mtr as customer required

Scaffolding Tube:

Outer Diameter: 38mm, 42mm, 48.3mm-48.6mm

Wall Thickness: 2.0mm, 2.5mm, 2.75mm, 3.0mm, 3.25mm, 3.85mm, 4.0mm

Length: 0.3mtr -18 mtr

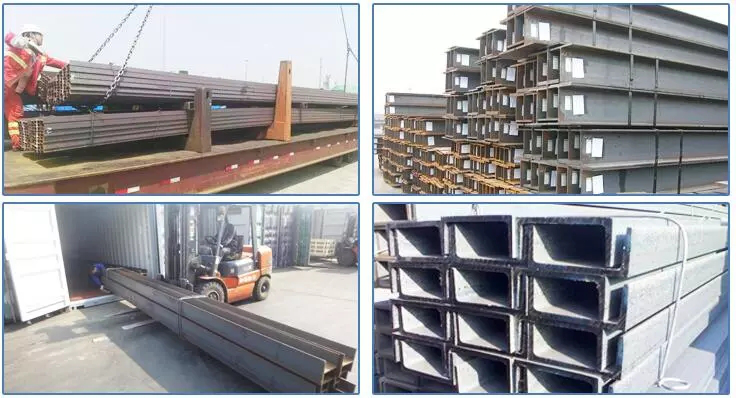

Process:

Seamless: Hot Rolled, Hot Explored

Welded: ERW, HFW

Coating: Hot-dipped Galvanised, Electrical Galvanised

Raw Material:

Seamless: Pipe Billet( Hot Rolled, or Con-casting), Mother Pipe

Welded: Hot Rolled Steel Coil (HRC) , Cold Rolled Steel Coil (CRC), Pre-pained Galvanized Steel Strip

End: Square cut, Burr removed

Surface:Lightly oiled, Hot dip galvanized, Electro galvanized, Black

Heat Treatment: Bright Annealed, Black Annealed

Packing: Plastic plugs in both ends, Hexagonal bundles of max. 2,000kg with several steel strips, Two tags on each bundle, Wrapped in waterproof paper, PVC sleeve, and sackcloth with several steel strips

Test: Chemical Component Analysis, Mechanical Properties (Ultimate tensile strength, Yield

strength, Elongation), Technical Properties (Flattening Test, Flaring Test, Bending Test, Hardness Test, Blow Test, Impact Test etc), Exterior Size Inspection

Mill Test Certificate: EN 10204/3.1B

Square tubes sizes

|

Size (mm) |

Wall Thickness (mm) |

Size (mm) |

Wall Thickness (mm) |

|

20*20 |

1.2 |

70*70 60*80 100*40 |

1.8 |

|

1.3 |

2 |

||

|

1.4-1.5 |

2.2 |

||

|

1.7 |

2.3 |

||

|

1.8 |

2.5-4.0 |

||

|

2 |

4.5-5.0 |

||

|

2.2 |

5.5-5.75 |

||

|

2.3 |

75*75 60*90 100*50 |

1.8 |

|

|

2.5-2.75 |

2 |

||

|

25*25 20*30 |

1.2 |

2.2 |

|

|

1.3 |

2.3 |

||

|

1.5 |

2.5-4.0 |

||

|

1.7 |

4.5-5.0 |

||

|

1.8 |

5.5-5.75 |

||

|

2 |

80*80 100*60 100*80 120*60 |

2 |

|

|

2.3-2.3 |

2.2 |

||

|

2.5-3.0 |

2.3 |

||

|

30*30 30*40 25*40 20*40 |

1 |

2.5-4.0 |

|

|

1.2 |

4.5-5.0 |

||

|

1.3 |

5.5-5.75 |

||

|

1.5 |

7.5-7.75 |

||

|

1.7 |

100*100 120*80 |

2 |

|

|

1.8 |

2.2 |

||

|

2 |

2.3 |

||

|

2.2 |

2.5-5.0 |

||

|

2.3 |

5.5-5.75 |

||

|

2.5*2.75 |

7.5-7.75 |

||

|

3 |

120*120 140*80 150*100 160*80 |

2.5 |

|

|

40*40 30*50 25*50 |

1.2 |

2.75 |

|

|

1.3 |

3 |

||

|

1.4-1.5 |

3.25-5.0 |

||

|

1.7 |

5.5-7.0 |

||

|

1.8 |

7.5-7.75 |

||

|

2 |

140*140 150*150 200*100 |

3.5-4.0 |

|

|

2.2-2.3 |

4.5-5.0 |

||

|

2.5-4.0 |

5.25-7.0 |

||

|

50*50 60*40 30*60 40*50 |

1.5 |

7.5-7.75 |

|

|

1.7 |

160*160 180*180

|

3 |

|

|

1.8 |

3.5 |

||

|

2 |

3.75 |

||

|

2.2 |

4.0-5.0 |

||

|

2.3 |

5.25-5.75 |

||

|

2.5*-4.0 |

7.5-7.75 |

||

|

4.25-5.0 |

60*60 40*80 75*75 50*70 50*80 |

2.3 |

|

|

60*60 40*80 75*45 50*70 50*80 |

1.5 |

2.5-4.0 |

|

|

1.7 |

4.25-5.0 |

||

|

1.8 |

5.5-5.75 |

||

|

2 |

/ |

||

|

2.2-2.3 |

/ |

Available Quality Standards

ASTM A500 Cold Formed Welded and Seamless Carbon Steel Steel Structural Tubing in Round and Shapes

EN 10210 Hot finished structural hollow sections of non-alloy and fine grain structural steels

EN 10219 Cold formed welded structural hollow sections of non-alloy and fine grain steels

ASTM A53 used as structural steel or for low-pressure plumbing

Standard Corner Radius(Structural Sizes:)

Max. 3 x Nominal Wall Thickness

|

Mechanical Sizes |

Structural Sizes |

||

|

Largest Nominal Outside Dimension |

Outside Tolerance at all Sides at Corners |

Largest Nominal Outside Dimension |

Outside Tolerance at all Sides at Corners |

|

3/16 to 5/8 |

± 0.004 |

2 1/2 and under |

± 0.020 |

|

over 5/8 to 1 1/8 |

± 0.005 |

over 2 1/2 to 3 1/2 |

± 0.020 |

|

over 1 1/8 to 1 1/2 |

± 0.006 |

over 3 1/2 to 5 1/2 |

± 0.030 |

|

over 1 1/2 to 2 |

± 0.008 |

over 5 1/2 |

± 1% |

|

over 2 to 3 |

± 0.010 |

||

|

over 3 to 4 |

± 0.020 |

||

|

over 4 to 6 |

± 0.020 |

||

|

over 6 to 8 |

± 0.025 |

||

Straightness

Mechanical Sizes: Max. 1/16″ in 3 feet

Structural Sizes: Max. 1/8″ x Number of feet of total length divided by 5

Wall Thickness

Mechanical & Structural Sizes: ± 10% of Nominal Wall Thickness

Squareness of Sides

Mechanical Sizes: Max: ± b = c x 0.006″

b = Tolerance for out-of-square

c = Largest external dimension across flats

Structural Sizes: Adjacent sides may deviate from 90 ° by ± 2 °

Maximum Twist (Mechanical & Structural Sizes)

|

Largest Dimension, inches |

Max. Twist*, inches |

|

over 1/2 to 1 1/2 |

0.050 |

|

over 1 1/2 to 2 1/2 |

0.062 |

|

over 2 1/2 to 4 |

0.075 |

|

over 4 to 6 |

0.087 |

|

over 4 to 8 |

0.100 |

Convexity & Concavity(Mechanical & Structural Sizes)

|

Largest Nominal O.D., Inches |

Tolerance ± Inches |

|

2 1/2 and under |

± 0.010 |

|

over 2 1/2 to 4 |

± 0.015 |

|

over 4 to 8 |

± 0.025 |

Structural Tubing A 500 Requirements

|

Grades |

Chemical |

Physical |

||||||

|

C Max. % |

Mn Max. % |

P Max. % |

S Max. % |

Cu Max. % |

Tensile strength, min. psi |

Yield strength, min. psi |

Elongation in 2 in. |

|

|

Grade B |

0.26 |

/ |

0.04 |

0.05 |

0.20 |

58,000 |

46,000 |

23 |

|

Grade C |

0.23 |

1.35 |

0.04 |

0.05 |

0.20 |

62,000 |

50,000 |

21 |

Bright Annealed, Black Annealed

Plastic plugs in both ends, Hexagonal bundles of max. 2,000kg with several steel strips, Two tags on each bundle, Wrapped in waterproof paper, PVC sleeve, and sackcloth with several steel strips

Inspection: Chemical Component Analysis, Mechanical Properties