Alloy Seamless Pipe

OD:6-720MM

WT:0.5-120MM

Length:3-16M

Application:Petroleum, Chemical Engineering, Electricity, Boiler

Standard:ASTM A335/A335M, ASTM A213/213M, DIN17175-79, JIS3467-88,GB5310-95

Material:P5,T5,P11,P12,STFA22, P22, T91, T9,WB36

Alloy pipe is a kind of seamless steel pipe, its performance is much higher than that of general seamless steel pipe, because this type of steel pipe contains more Cr, its high temperature resistance, low temperature resistance, corrosion resistance performance is much better than other Steel pipe , so the alloy pipe is widely used in petroleum, aerospace, chemical, electric power, boiler, military and other industries.

| Product | SEAMLESS / ERW / SAW ALLOY STEEL PIPE |

| Dimension | 6 mm - 1080 mm |

| Thickness | 1mm - 135 mm |

| Length | 3 m - 12 m or according to the requirements of clients |

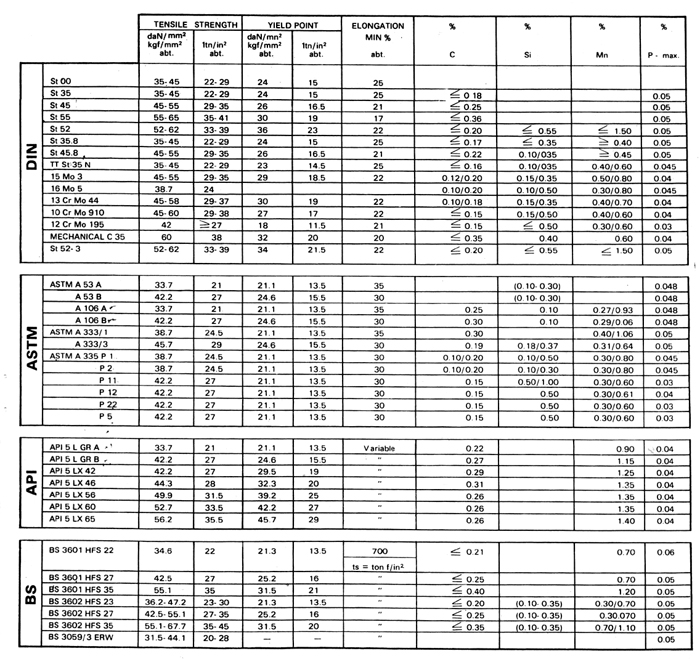

| Standard | ASTM GB DIN |

| Steel grade | A106/53/179/214/192/210 A/B/CST37.2/35.4/35.8/52/52.3/52.4/42/4510# 20# 45#P2, P12, P11, P22, P5, P9, P91T2, T11,T5,T9,T22, 4140, 12CrMo, 15CrMo, 12Cr2Mo, 1Cr5Mo, 2CrMo4, 1Cr9Mo, 10CrMo910, etc. |

| Trade terms | FOB/CIF/CFR |

| Payment terms | T/T, L/C |

| Delivery port | Tianjin, China |

| Delivery time | 10 or according to the real quantity of the tubes |

| Surface treatment | Black paintingVarnish painting3PEHot galvanizedor other coating according to your requirementsBare tube |

| End of tubes | Beveled, plain, thread, plastic caps |

| Inspection | Ultrasonic examination, eddy inspection, hydrosttic testing etc. |

| Package | Bundles, loosen or according to your requirements |

| Certificate | API 5L/5CT, ISO, PED etc. |

Chemical Composition

| C, % | Mn, % | P, % | S, % | Si, % | Cr, % | Mo, % |

| 0.05-0.15 | 0.30-0.60 | 0.025 max | 0.025 max | 0.50-1.00 | 1.00-1.50 | 0.44-0.65 |

Mechanical Properties

| Tensile Strength, MPa | Yield Strength, MPa | Elongation, % |

| 415 min | 205 min | 30 min |

Outside Diameter & Tolerance

| ASTM A450 | Hot rolled | Outside Diameter, mm | Tolerance, mm |

| OD≤101.6 | +0.4/-0.8 | ||

| 101.6<OD≤190.5 | +0.4/-1.2 | ||

| 190.5<OD≤228.6 | +0.4/-1.6 | ||

| Cold Drawn | Outside Diameter, mm | Tolerance, mm | |

| OD<25.4 | ±0.10 | ||

| 25.4≤OD≤38.1 | ±0.15 | ||

| 38.1<OD<50.8 | ±0.20 | ||

| 50.8≤OD<63.5 | ±0.25 | ||

| 63.5≤OD<76.2 | ±0.30 | ||

| 76.2≤OD≤101.6 | ±0.38 | ||

| 101.6<OD≤190.5 | +0.38/-0.64 | ||

| 190.5<OD≤228.6 | +0.38/-1.14 | ||

| ASTM A530 & ASTM A335 | NPS | Outside Diameter, inch | Tolerance, mm |

| 1/8≤OD≤1-1/2 | ±0.40 | ||

| 1-1/2<OD≤4 | ±0.79 | ||

| 4<OD≤8 | +1.59/-0.79 | ||

| 8<OD≤12 | +2.38/-0.79 | ||

| OD>12 | ±1% |

Wall thickness & Tolerance

| ASTM A450 | Hot rolled | Outside Diameter, mm | Tolerance, % |

| OD≤101.6, WT≤2.4 | +40/-0 | ||

| OD≤101.6, 2.4<WT≤3.8 | +35/-0 | ||

| OD≤101.6, 3.8<WT≤4.6 | +33/-0 | ||

| OD≤101.6, WT>4.6 | +28/-0 | ||

| OD>101.6, 2.4<WT≤3.8 | +35/-0 | ||

| OD>101.6, 3.8<WT≤4.6 | +33/-0 | ||

| OD>101.6, WT>4.6 | +28/-0 | ||

| Cold Drawn | Outside Diameter, mm | Tolerance, % | |

| OD≤38.1 | +20/-0 | ||

| OD>38.1 | +22/-0 | ||

| ASTM A530 | NPS | Outside Diameter, inch | Tolerance, % |

| 1/8≤OD≤2-1/2 | +20.0/-12.5 | ||

| 3≤OD≤18, WT/OD≤5% | +22.5/-12.5 | ||

| 3≤OD≤18, WT/OD>5% | +15.0/-12.5 | ||

| OD≥20, WT/OD≤5% | +22.5/-12.5 | ||

| OD≥20, WT/OD>5% | +15.0/-12.5 |

ASTM A335–for Seamless Ferritic Alloy-Steel Pipe for High-Temperature Service

ASTM A519–for Seamless Carbon and Alloy Steel Mechanical Tubing

ASTM A213–for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Super heater, and Heat-Exchange Tubes

ASTM ASME (S)A-335/(S)A-335M Grade and Chemical Composition

| Grade | UNS | C≤ | Mn | P≤ | S≤ | Si≤ | Cr | Mo |

| P1 | K11522 | 0.10~0.20 | 0.30~0.80 | 0.025 | 0.025 | 0.10~0.50 | - | 0.44~0.65 |

| P2 | K11547 | 0.10~0.20 | 0.30~0.61 | 0.025 | 0.025 | 0.10~0.30 | 0.50~0.81 | 0.44~0.65 |

| P5 | K41545 | 0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.50 | 4.00~6.00 | 0.44~0.65 |

| P5b | K51545 | 0.15 | 0.30~0.60 | 0.025 | 0.025 | 1.00~2.00 | 4.00~6.00 | 0.44~0.65 |

| P5c | K41245 | 0.12 | 0.30~0.60 | 0.025 | 0.025 | 0.50 | 4.00~6.00 | 0.44~0.65 |

| P9 | S50400 | 0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.50~1.00 | 8.00~10.00 | 0.44~0.65 |

| P11 | K11597 | 0.05~0.15 | 0.30~0.61 | 0.025 | 0.025 | 0.50~1.00 | 1.00~1.50 | 0.44~0.65 |

| P12 | K11562 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.50 | 0.80~1.25 | 0.44~0.65 |

| P15 | K11578 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 1.15~1.65 | - | 0.44~0.65 |

| P21 | K31545 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.50 | 2.65~3.35 | 0.80~1.60 |

| P22 | K21590 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.50 | 1.90~2.60 | 0.87~1.13 |

| P91 | K91560 | 0.08~0.12 | 0.30~0.60 | 0.020 | 0.010 | 0.20~0.50 | 8.00~9.50 | 0.85~1.05 |

| P92 | K92460 | 0.07~0.13 | 0.30~0.60 | 0.020 | 0.010 | 0.50 | 8.50~9.50 | 0.30~0.60 |

Note: (S)A335 P91 other chemical composition are : V 0.18~0.25; N 0.030~0.070; Ni ≤ 0.40; Al ≤ 0.04 ; Nb 0.06~0.10

(S)A335 P92 other chemical composition are : V 0.15~0.25; N 0.030~0.070; Ni ≤ 0.40; Al ≤ 0.04 ; Nb 0.04~0.09; W 1.5~2.00 ; B 0.001~0.006

Black coating , oil/varnish ,FBE,2PE,3PE, galvanized etc Packaging Detail: Packing in bundles or for the client’s requirement

Before Painting

Preparation of painting specification involves understanding environmental factors, location of piping (indoor or outdoor), insulation requirements, operating and design temperatures. It may also involve local rules and regulations as well as availability of materials.

Painting Workflow

- Ensure all tests are performed on piping system before starting painting work.

- Clean painting surface to remove oils, grease, dirt.

- Ensure proper room temperature and humidity levels.

- Use hand tools, machine tools, shot blasters etc to clean surface as per relevant standards and project requirements.

- Apply primer within 4 hours of surface preparation.

- Apply paint coats after previous coats have dried up, as per instructions of paint manufacturer.

Components Requiring Painting

• Carbon steel ducts, furnaces and stacks require painting.

• All un-insulated equipments like columns, vessels, drums, heat exchangers, pumps, compressors, electrical panels, motors etc. require painting.

• All structural componets like steel members, platforms, ladders,handrails etc. required painting.

Types of Painting Methods

• Painting by Brush

• Painting by Air Spray Painting Machine

• Painting by Airless Spray Painting Machine

Surfaces that should not be painted.

Non-ferrous materials like Aluminium are not required to be painted. Also other surfaces like Valve Stems etc. Checkout this complete list of surfaces that should not be painted.

Characteristics of Piping Paint Material

Paint material used for painting pipes and equipments must adhere to certain requirements as per project specification .Check out these typical requirements for various types of primers and paints.

Typical Piping Painting Systems

Check out these combinations of typical piping painting systems which comprise of surface preparation, primer coats and top coats.

Humidity Requirements During Painting

Proper weather conditions surrounding the place of painting work is essential w.r.t. humidity levels and room temperature. Check out these humidity and temperature requirements.

Qualification Criteria for Painting Contractor

Painting contractor needs to posses these qualifications for good quality of painting work in time.

Inspection and Testing Procedure

Sound inspection and testing procedure must be in place to ensure good quality of painting work. Check out this article for complete information on inspection and testing procedure.