Alloy Welded Pipe

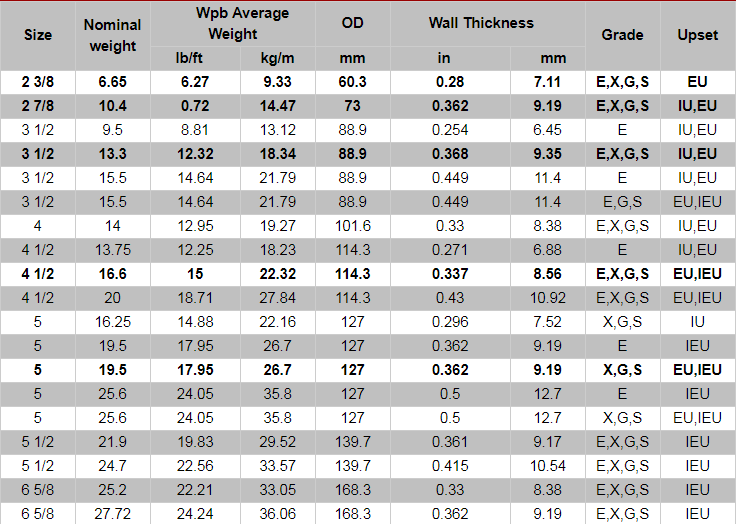

OD:6-720MM

WT:0.5-120MM

Length:3-16M

Application:

Construction Hall Structure, Sea Trestle, Airport Structure, Shipbuilding, Security Door Frames, Garage Doors, Strengthening Liners of Steel Doors and Windows, Indoor Partition Walls, Cable Bridge Structures and Expressway Safety Guards, Balustrade, Decorating, Residential, Ornamental Pipes

Agriculture: Agricultural Equipment

Industry Machinery, Solar Stent, Offshore Oil Field, Mine Equipment, Electromechanical Hardware, , heavy engineering, Mining and Resources, Process Engineering, Materials Handling,Mechanical Parts

Traffic Walking Rails, Roll-up Doors, Guardrail, Plaza Structure, Signage, Road Furniture, Fencing Logistics Storage Supermarket Shelves, Containers, Transport Industries, Commercial Construction Other Sports Apparatus, Leisure Equipment, Furniture, School Furniture

Material Storage Racks, Pallets, Hydraulic Platforms, Trusses, Columns, Purlins, Greenhouse Stands Towers

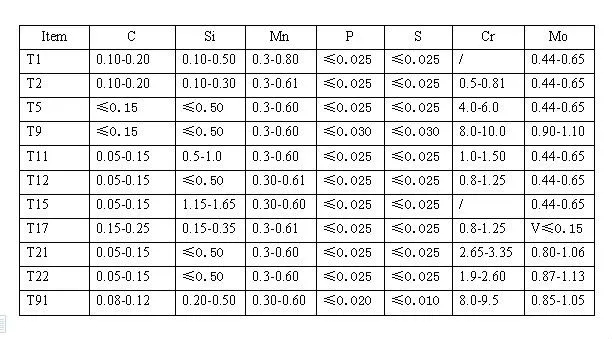

Chemical details:

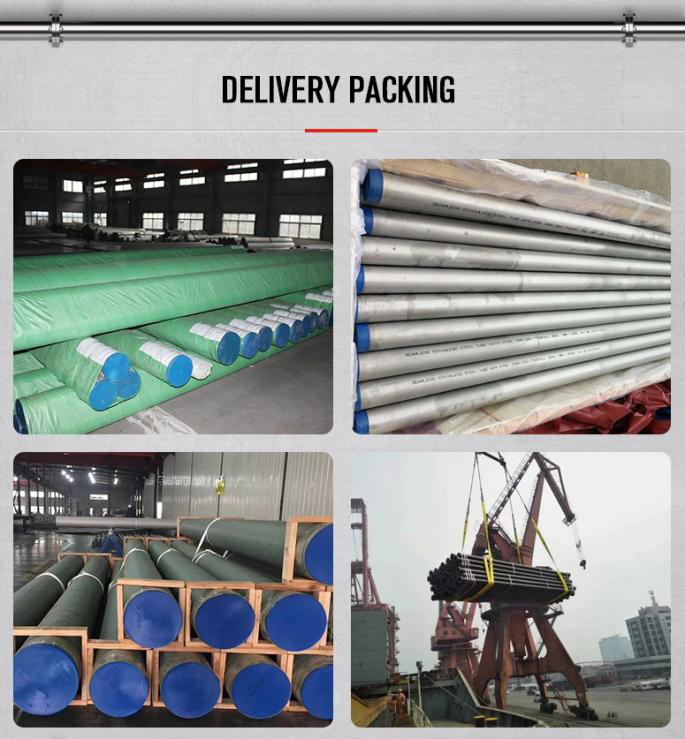

Black coating , oil/varnish ,FBE,2PE,3PE, galvanized etc Packaging Detail: Packing in bundles or for the client’s requirement

Before Painting

Preparation of painting specification involves understanding environmental factors, location of piping (indoor or outdoor), insulation requirements, operating and design temperatures. It may also involve local rules and regulations as well as availability of materials.

Painting Workflow

- Ensure all tests are performed on piping system before starting painting work.

- Clean painting surface to remove oils, grease, dirt.

- Ensure proper room temperature and humidity levels.

- Use hand tools, machine tools, shot blasters etc to clean surface as per relevant standards and project requirements.

- Apply primer within 4 hours of surface preparation.

- Apply paint coats after previous coats have dried up, as per instructions of paint manufacturer.

Components Requiring Painting

• Carbon steel ducts, furnaces and stacks require painting.

• All un-insulated equipments like columns, vessels, drums, heat exchangers, pumps, compressors, electrical panels, motors etc. require painting.

• All structural componets like steel members, platforms, ladders,handrails etc. required painting.

Types of Painting Methods

• Painting by Brush

• Painting by Air Spray Painting Machine

• Painting by Airless Spray Painting Machine

Surfaces that should not be painted.

Non-ferrous materials like Aluminium are not required to be painted. Also other surfaces like Valve Stems etc. Checkout this complete list of surfaces that should not be painted.

Characteristics of Piping Paint Material

Paint material used for painting pipes and equipments must adhere to certain requirements as per project specification .Check out these typical requirements for various types of primers and paints.

Typical Piping Painting Systems

Check out these combinations of typical piping painting systems which comprise of surface preparation, primer coats and top coats.

Humidity Requirements During Painting

Proper weather conditions surrounding the place of painting work is essential w.r.t. humidity levels and room temperature. Check out these humidity and temperature requirements.

Qualification Criteria for Painting Contractor

Painting contractor needs to posses these qualifications for good quality of painting work in time.

Inspection and Testing Procedure

Sound inspection and testing procedure must be in place to ensure good quality of painting work. Check out this article for complete information on inspection and testing procedure.