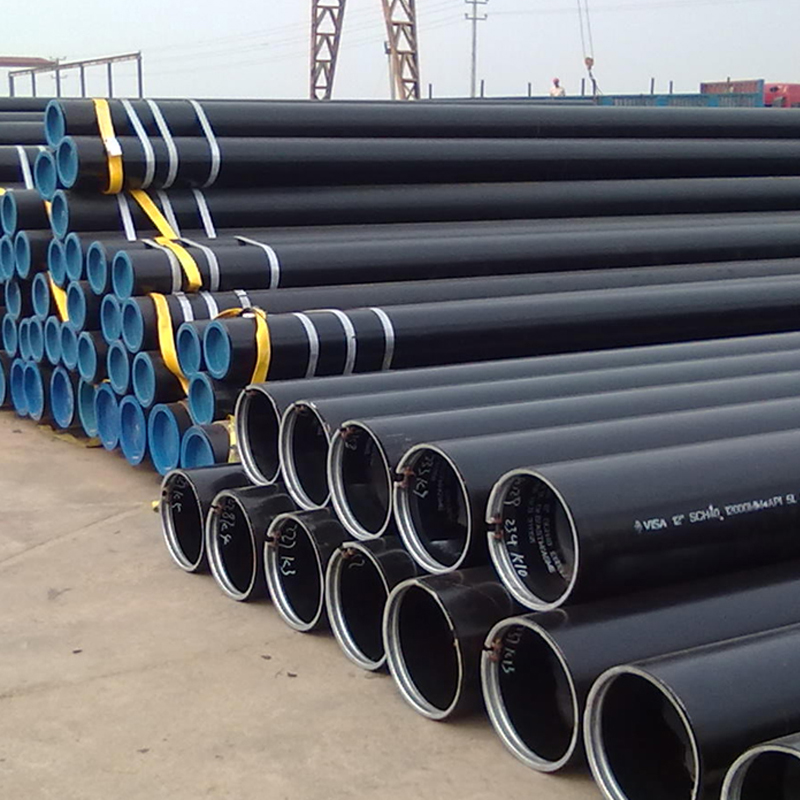

Line Pipe

Used for conveying gas, water, and oil in both and natural gas industries etc.

Casing:Casing is a large-diameter pipe that serves as the structural retainer for the walls of oil and gas wells, or well bore.It is inserted into a well bore and cemented in place to protect both subsurface formations and the wellbore from collapsing and to allow drilling fluid to circulate and extraction to take place. Steel Casing Pipes have smooth wall & minimum yield strength of 35,000 psi.

Tubing: Tubing is pipe used for the transportation of crude oil and natural gas from an oil or gas layer to the surface after drilling is complete. It is made to withstand the pressure generated from the extraction process. Tubing is manufactured in the same way as casing, except that an additional process known as "upsetting" is applied to thicken the pipes.

Chemical Analysis (%):

|

Standard |

Type of pipe |

Class |

Grade |

C |

Si |

Mn |

P |

S |

V |

Nb |

Ti |

|

max |

max |

max |

max |

max |

max |

max |

max |

||||

|

API SPEC 5L |

SMLS |

PLS1 |

L245 B L290 X42 L320 X46 L360 X52 L390 X56 L415 X60 L450 X65 L485 X70 L245N BN |

0.28 0.28 0.28 0.28 0.28 0.28 0.28 0.28 0.24 |

0.4 |

1.20 1.30 1.40 1.40 1.40 1.40 1.40 1.40 1.20 |

0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.025 |

0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.015 |

——— |

——— |

0.04 |

|

PLS2 |

L290N X42N |

0.24 |

0.4 |

1.2 |

0.025 |

0.015 |

0.06 |

0.05 |

0.04 |

||

|

L320N X46N |

0.24 |

0.4 |

1.4 |

0.025 |

0.015 |

0.07 |

0.05 |

0.04 |

|||

|

L360N X52N |

0.24 |

0.45 |

1.4 |

0.025 |

0.015 |

0.1 |

0.05 |

0.04 |

|||

|

L390N X56N |

0.24 |

0.45 |

1.4 |

0.025 |

0.015 |

0.1 |

0.05 |

0.04 |

|||

|

L415N X60N |

0.24 |

0.45 |

1.4 |

0.025 |

0.015 |

0.1 |

0.05 |

0.04 |

|||

|

WELD |

PLS1 |

L245 B |

0.26 |

- |

1.2 |

- |

0.03 |

0.03 |

- |

- |

|

|

L290 X42 |

0.26 |

- |

1.3 |

- |

0.03 |

0.03 |

- |

- |

|||

|

L320 X46 |

0.26 |

- |

1.4 |

- |

0.03 |

0.03 |

- |

- |

|||

|

L360 X52 |

0.26 |

- |

1.4 |

- |

0.03 |

0.03 |

- |

- |

|||

|

L390 X56 |

0.26 |

- |

1.4 |

- |

0.03 |

0.03 |

- |

- |

|||

|

L415 X60 |

0.26 |

- |

1.4 |

- |

0.03 |

0.03 |

- |

- |

|||

|

L450 X65 |

0.26 |

- |

1.45 |

- |

0.03 |

0.03 |

- |

- |

|||

|

L485 X70 |

0.26 |

- |

1.65 |

- |

0.03 |

0.03 |

- |

- |

|||

|

PLS2 |

L245M BM |

0.22 |

0.45 |

1.2 |

0.025 |

0.015 |

0.05 |

0.05 |

0.04 |

||

|

L290M X42M |

0.22 |

0.45 |

1.3 |

0.025 |

0.015 |

0.05 |

0.05 |

0.04 |

|||

|

L320M X46M |

0.22 |

0.45 |

1.3 |

0.025 |

0.015 |

0.05 |

0.05 |

0.04 |

|||

|

L360M X52M |

0.22 |

0.45 |

1.4 |

0.025 |

0.015 |

- |

- |

- |

|||

|

L390M X56M |

0.22 |

0.45 |

1.4 |

0.025 |

0.015 |

- |

- |

- |

|||

|

L415M X60M |

0.12 |

0.45 |

1.6 |

0.025 |

0.015 |

- |

- |

- |

|||

|

L450M X65M |

0.12 |

0.45 |

1.6 |

0.025 |

0.015 |

- |

- |

- |

|||

|

L485M X70M |

0.12 |

0.45 |

1.7 |

0.025 |

0.015 |

- |

- |

- |

|||

|

L555M X80M |

0.12 |

0.45 |

1.85 |

0.025 |

0.015 |

- |

- |

- |

Mechanical Properities:

|

Standard |

Class |

Grade |

Yield strength not less than (MPa) |

Tensile strength (MPa) |

Elongation(%) |

Y.S/T.S |

|

|

API SPEC 5L ISO 3183 |

PLS1 |

L245B |

min |

245 |

415 |

b |

- |

|

L290X42 |

min |

290 |

415 |

b |

- |

||

|

L320X46 |

min |

320 |

435 |

b |

- |

||

|

L360X52 |

min |

360 |

460 |

b |

- |

||

|

L390X56 |

min |

390 |

490 |

b |

- |

||

|

L415X60 |

min |

415 |

520 |

b |

- |

||

|

L450X60 |

min |

450 |

535 |

b |

- |

||

|

L485X70 |

min |

485 |

570 |

b |

- |

||

|

PLS2 |

L245N BN |

min |

245 |

415 |

b |

- |

|

|

L245M BM |

max |

450 |

760 |

b |

0.93 |

||

|

L290NX42N |

min |

290 |

415 |

b |

- |

||

|

L290MX42M |

max |

495 |

760 |

b |

0.93 |

||

|

L320NX46N |

min |

320 |

435 |

b |

- |

||

|

L320MX46M |

max |

525 |

760 |

b |

0.93 |

||

|

L360NX52N |

min |

360 |

460 |

b |

- |

||

|

L360MX52M |

max |

530 |

760 |

b |

0.93 |

||

|

L390NX56N |

min |

390 |

490 |

b |

- |

||

|

L390MX56M |

max |

545 |

760 |

b |

0.93 |

||

|

L415NX60N |

min |

415 |

520 |

b |

- |

||

|

L415MX60M |

max |

565 |

760 |

b |

0.93 |

||

|

L450MX65M |

min |

450 |

535 |

b |

- |

||

|

max |

600 |

760 |

b |

0.93 |

|||

|

L485MX70M |

min |

485 |

570 |

b |

- |

||

|

max |

635 |

760 |

b |

0.93 |

|||

|

L555MX80M |

min |

555 |

625 |

b |

- |

||

|

max |

705 |

825 |

b |

0.93 |

Toughness:

|

Standard |

Grade |

Transverse minimum impact of Pipe body |

Transverse minimum impact of weld (J) |

|||||

|

(J) |

||||||||

|

D=508 |

508mm<D=762mm |

762mm<D=914mm |

914mm<D=1219mm |

1219mm<D=1422mm |

D<1422mm |

D=1422mm |

||

|

API SPEC 5L |

=L415×60 |

27(20) |

27(20) |

40(30) |

40(30) |

40(30) |

27(20) |

40(30) |

|

>L415×60 |

27(20) |

27(20) |

40(30) |

40(30) |

54(40) |

27(20) |

40(30) |

|

|

=L450×65 |

||||||||

|

>L450×65 |

27(20) |

27(20) |

40(30) |

40(30) |

54(40) |

27(20) |

40(30) |

|

|

=L485×70 |

||||||||

|

>L485×70 |

40(30) |

40(30) |

40(30) |

40(30) |

54(40) |

27(20) |

40(30) |

|

|

=L555×80 |

||||||||

Note:(1)The values in the table be suitable for the full size standard sample.

(2) The values inside bracket is the minimum single value, outside bracket is the average value.

(3) Test Temperature: 0°C.

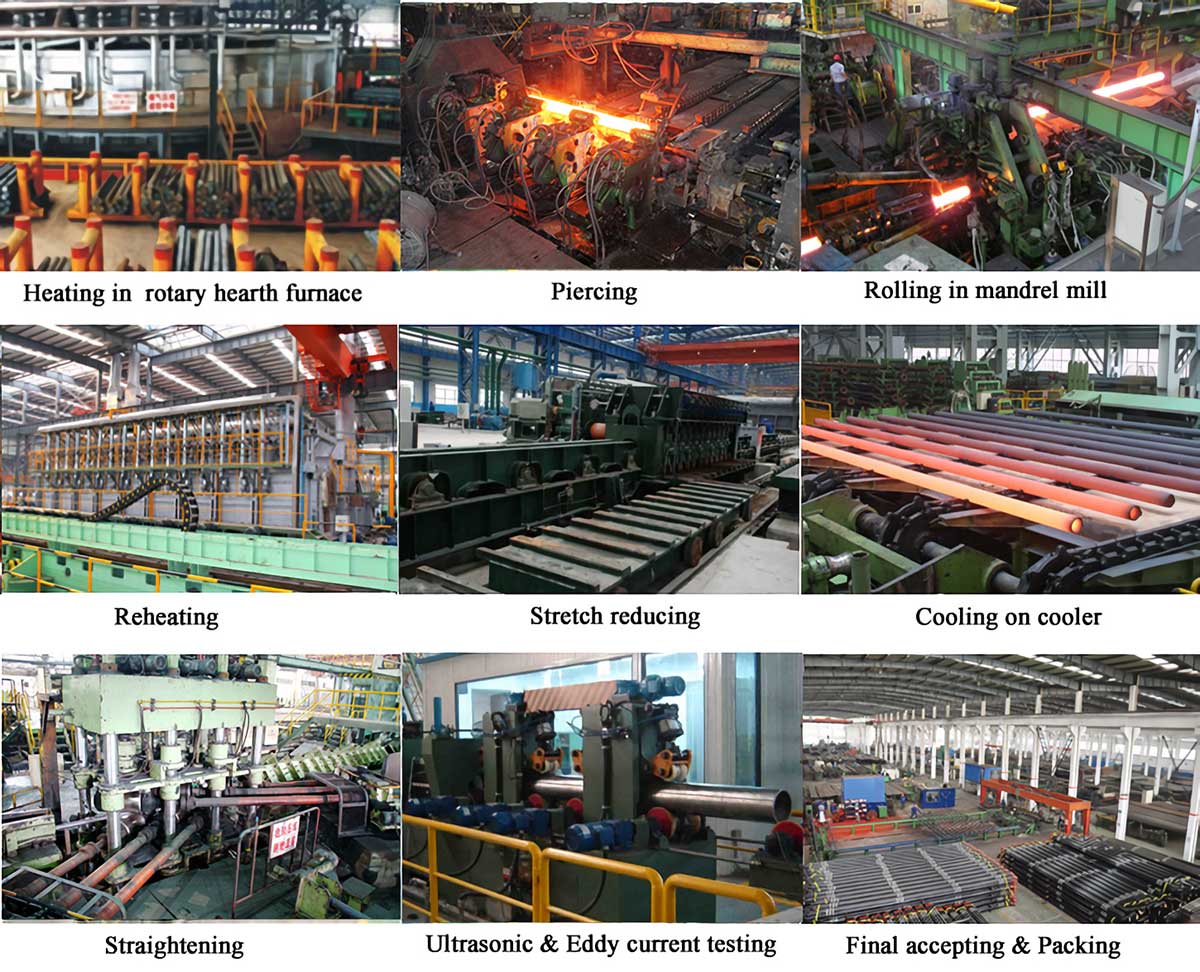

Hot Rolling Seamless Steel Line Pipe Manufacturing / Production processes

Rolled Round Billets – Examination – Cut Off – Heating – Piercing – Elongation – Slight Tension Reducing – Straightening – Corp End Cutting Off – Visual Inspection – NDT – Hydrostatic Test – Ends Procession – Product Inspection – Painting and Marking – Packing – Warehousing

Cold Drawn (Rolled) seamless steel pipe manufacturing process

Mother pipe (Normally for hot rolled pipe) – Inspection – Annealing – Ends Treatment (Hitting and Drilling hole) – Pickling – Grinding – Phosphorization (Annoit) – Cold Drawn (Rolled) – Degreasing and Cleaning – Heat treatment (Solution treatment) – Straightening – Hydrostatic test – Painting and Marking – Warehousing