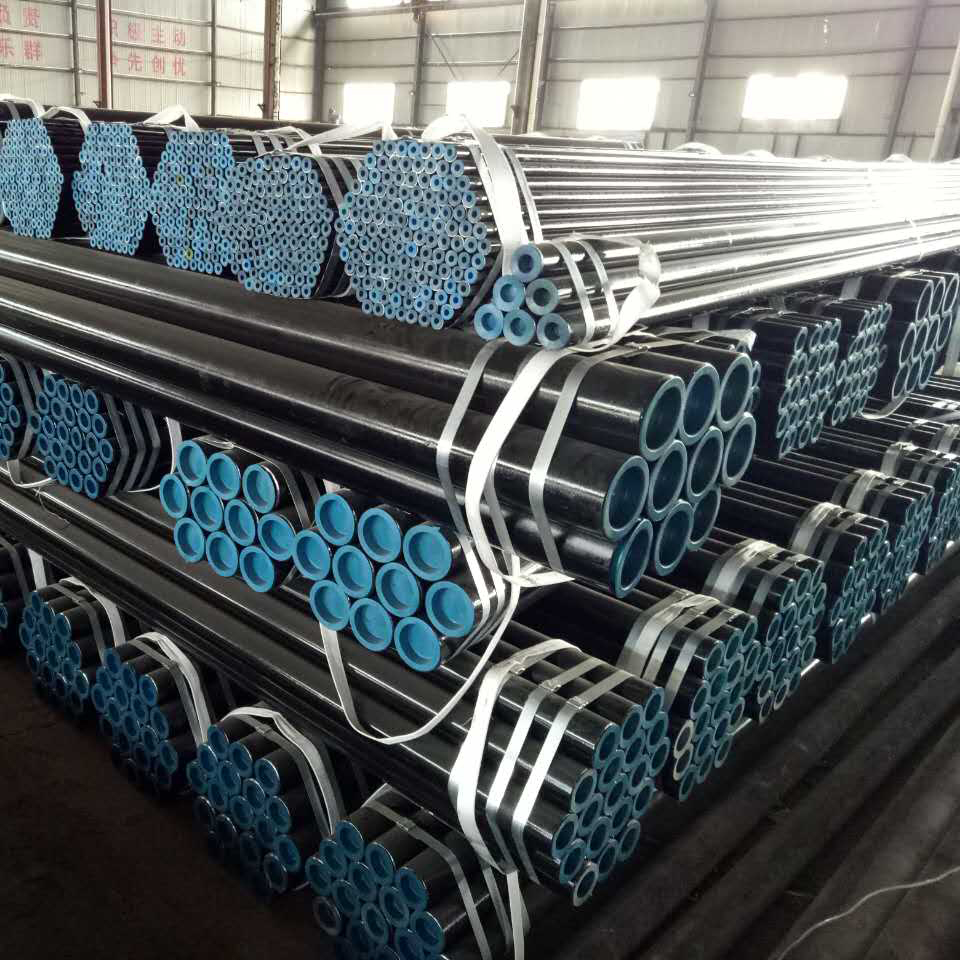

Hot Expanded Seamless Pipe

The hot expanding steel pipe is hot expanded seamless pipes, which is relatively low density but the contraction of the strong steel pipe (seamless pipe) can be referred to as thermal expansion. A process of skew rolling or drawing method to expand the pipe diameter. Steel pipe thickening in a short period of time, can produce non-standard and special types of seamless tubes with low-cost and high production efficiency, the current international developments in the field of tube rolling.

Hot expand pipe is by expanding the diameter of pipe to finish processes - thermal expansion process of the production of steel pipe. Hot expansion pipe are commonly referred to hot expanded seamless steel pipes.

Technical Parameters of Hot Expanding Seamless Steel Pipe :

|

Nominal size |

Outside |

Nominal Wall Thickness (mm) |

|||||||||||||

|

DN |

NPS |

OD(MM) |

SCH |

SCH |

SCH |

STD |

SCH |

SCH |

XS |

SCH |

SCH |

SCH |

SCH |

SCH |

XXS |

|

200 250 300 |

8 10 12 |

219.1 273.1 323.9 |

3.76 4.19 4.57 |

6.35 6.35 6.35 |

7.04 7.80 8.38 |

8.18 9.27 9.53 |

8.18 9.27 10.31 |

10.31 12.70 14.27 |

12.70 12.70 12.70 |

12.70 15.09 17.48 |

15.09 18.26 21.44 |

18.26 21.44 25.40 |

20.62 25.40 28.58 |

23.01 28.58 33.32 |

22.23 25.40 25.40 |

|

350 400 450 |

14 16 18 |

355.6 406.4 457.2 |

6.35 6.35 6.35 |

7.92 7.92 7.92 |

9.53 9.53 11.13 |

9.53 9.53 9.53 |

11.13 12.70 14.27 |

15.09 16.66 19.05 |

12.70 12.70 12.70 |

19.05 21.44 23.83 |

23.83 26.19 29.36 |

27.79 30.96 34.93 |

31.75 36.53 39.67 |

35.71 40.49 45.24 |

— — |

|

500 550 600 |

20 22 24 |

508 559 610 |

6.35 6.35 6.35 |

9.53 9.53 9.53 |

12.70 12.70 14.27 |

9.53 9.53 9.53 |

15.09 — 17.48 |

20.62 22.23 24.61 |

12.70 |

26.19 28.58 30.96 |

32.54 34.93 38.89 |

38.10 41.28 46.02 |

44.45 47.63 52.37 |

50.01 53.98 59.54 |

— — |

|

500 550 600 |

20 22 24 |

508 559 610 |

6.35 6.35 6.35 |

9.53 9.53 9.53 |

12.70 12.70 14.27 |

9.53 9.53 9.53 |

15.09 — 17.48 |

20.62 22.23 24.61 |

12.70 12.70 12.70 |

26.19 28.58 30.96 |

32.54 34.93 38.89 |

38.10 41.28 46.02 |

44.45 47.63 52.37 |

50.01 53.98 59.54 |

— — |

|

660 700 750 |

26 28 30 |

660 711 762 |

7.92 7.92 7.92 |

12.70 12.70 12.70 |

— 15.88 15.88 |

9.53 9.53 9.53 |

— — |

— — |

12.70 12.70 12.70 |

— — |

— — |

— — |

— — |

— — |

— — |

|

800 850 900 |

32 34 36 |

813 864 914 |

7.92 7.92 7.92 |

12.70 12.70 12.70 |

15.88 15.88 15.88 |

9.53 9.53 9.53 |

17.48 17.48 19.05 |

— — |

12.70 12.70 12.70 |

— — |

— — |

— — |

— — |

— — |

— — |

|

Outside Diameter (mm) / |

SCH |

SCH |

SCH |

STD |

SCH |

SCH |

XS |

SCH |

SCH |

SCH |

SCH |

SCH |

|

457 |

6.35 |

7.92 |

11.13 |

9.53 |

14.27 |

19.05 |

12.70 |

23.88 |

29.36 |

34.93 |

39.67 |

45.24 |

|

508 |

6.35 |

9.53 |

12.70 |

9.53 |

15.09 |

20.62 |

12.70 |

26.19 |

32.54 |

38.10 |

44.45 |

50.01 |

|

559 |

6.35 |

9.53 |

12.70 |

9.53 |

22.23 |

12.70 |

28.58 |

34.93 |

41.28 |

47.63 |

53.98 |

|

|

610 |

6.35 |

9.53 |

14.27 |

9.53 |

17.48 |

24.61 |

12.70 |

30.96 |

38.39 |

46.02 |

52.37 |

59.54 |

|

660 |

7.92 |

12.70 |

9.53 |

12.70 |

||||||||

|

711 |

7.92 |

12.70 |

15.88 |

9.53 |

12.70 |

|||||||

|

762 |

7.92 |

12.70 |

15.88 |

9.53 |

12.70 |

|||||||

|

Remark: The above standard and specification are just for reference, we can also produce customized product according to customer’s request. |

||||||||||||

Surface treatment of steel pipe:

In order to improve the service life of oil pipeline, surface treatment is usually carried out to facilitate the firm combination of steel pipe and anticorrosive coating.Common processing methods are: cleaning, tool derusting, pickling, shot blasting derusting four categories.

1 cleaningGrease, dust, lubricant, organic matter adhered on the surface of steel pipe, usually using solvent, emulsion to clean the surface.However, the rust, oxide skin and welding slag on the surface of the steel pipe cannot be removed, so other treatment methods are needed.Tool rust removalSteel pipe surface oxide, rust, welding slag, can use steel wire brush to clean and polish the surface treatment.Tool derusting can be divided into manual and power, manual tool derusting can reach Sa

2 level, power tool derusting can reach Sa3 level.If the surface of steel pipe is attached with a particularly strong oxide skin, it may be impossible to remove the rust with the help of tools, so we need to find other ways.

3 pickling Common pickling methods include chemistry and electrolysis.But only chemical pickling is used for pipeline corrosion protection.Chemical pickling can achieve a certain degree of cleanliness and roughness on the surface of steel pipe, which is convenient for subsequent anchor lines.Usually as a shot (sand) after reprocessing.

4 shot blasting for rust removalBy high power motor drive the high-speed rotating blades, steel grit, steel shot, segment, minerals and other abrasive wire under the action of centrifugal force on steel pipe surface spray and mass ejection, thoroughly remove rust, oxides and dirt on one hand, on the other hand, steel pipe under the action of abrasive violent impact and friction force, to achieve the required uniform roughness.Among the four treatment methods, shot blasting and derusting is an ideal treatment method for pipe derusting. Generally, shot blasting and derusting are mainly used for inner surface treatment of steel pipe, and shot blasting and derusting are mainly used for outer surface treatment of steel pipe.