Heavy Weight Drill Pipe

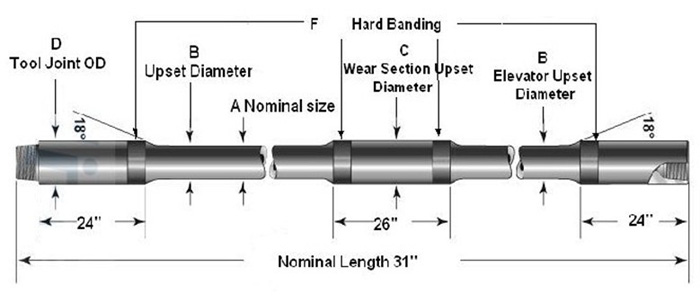

Integral heavy weight drill pipe is the transition zone between drill collar and drill pipe. It can not only reduce stress-formation in the connection of drill collar and drill pipe, but also reduce the wear on OD.

Integral heavy weight drill pipe is made from one piece of AISI 4145H solid bar, fully heat treated, all physical properties conform to API spec7 latest edition.

HWDP’s wear resistance hard banding is standard on tool joints connections and central upset. The types of hard banding include Arnco 100XT and100XT. All threads are phosphated, copperized or cold worked. All connections are equipped with pressed steel thread protectors. All theads are machined with CNC lathes –Double-shoudered and special threads.

Technical specifications and parameters

|

Size(in) |

O.D. (in) |

I.D. (in) |

Tool Joint O.D. (in) |

Tool Joint I.D. (in) |

Connection |

Max.elevator diameter (in) |

Central upset dia. (in) |

Min.drift dia.size(in) |

|

3 1/2 |

3 1/2 |

2 1/4 |

4 3/4 |

2 1/4 |

NC38 |

3 7/8 |

4 |

2 |

|

2 1/16 |

2 1/16 |

1 13/16 |

||||||

|

4 |

4 |

2 1/2 |

5 1/4 |

2 1/2 |

NC40 |

4 3/16 |

4 1/2 |

2 1/4 |

|

2 9/16 |

2 9/16 |

2 5/16 |

||||||

|

4 1/2 |

4 1/2 |

2 11/16 |

6 1/4 |

2 11/16 |

NC46 |

4 11/16 |

5 |

2 7/16 |

|

2 3/4 |

2 3/4 |

2 1/2 |

||||||

|

2 13/16 |

2 13/16 |

2 9/16 |

||||||

|

5 |

5 |

3 |

6 5/8 |

3 |

NC50 |

5 1/8 |

5 1/2 |

2 3/4 |

|

5 1/2 |

5 1/2 |

3 1/4 |

7 |

3 1/4 |

5 1/2 FH |

5 11/16 |

6 |

3 |

|

3 3/8 |

3 3/8 |

3 1/8 |

||||||

|

3 7/8 |

3 7/8 |

3 5/8 |

||||||

|

4 |

4 |

3 3/4 |

||||||

|

6 5/8 |

6 5/8 |

4 |

8 |

4 |

6 5/8 FH |

6 15/16 |

7 1/8 |

3 3/4 |

|

4 1/2 |

4 1/2 |

4 1/4 |

||||||

|

5 |

5 |

4 3/4 |

|

Spiral heavy weight drill pipe |

||||||||

| Specification mm |

Tube |

Joint |

||||||

| ID mm | Elevator upsetmm | elevator groove /Slip outside diametermm |

Screw in diametermm | Spiral groove depthmm | Thread Type | OD mm | ID mm | |

| 88.9(3 1/2) | 54 | 92.1 | 88.9 | 101.6 | 9.5 | NC38 | 120.6 | 54 |

| 114.3(4 1/2) | 69.8 | 117.5 | 114.3 | 127 | 12.7 | NC46 | 158.8 | 69.8 |

| 127.0(5) | 76.2 | 130.2 | 127 | 139.7 | 12.7 | NC50 | 165.1 | 76.2 |

| Steel Mark |

Chemical Composition% |

||||||||

| C | Si | Mn | P | S | Cr | Mo | Cu | Al | |

| 4145H | 0.42~0.48 | 0.15~0.35 | 0.90~1.20 | ≤0.03 | ≤0.03 | 0.90~1.20 | 0.15~0.25 | ≤0.2 | 0.025~0.045 |

| Other Elements:N≤0.015,Ni≤0.5 | |||||||||

|

Application |

Material |

Size |

Yield Strength (Min KSI) |

Ultimate Strength (Min KSI) |

Hardness Brinell (HB) |

Elongation (A%) |

Min CHarpy (ft-lbs @+20°C) |

|

Integral Standard |

AISI 4145H Modified |

All |

110 |

140 |

285 to 340 |

13 |

40 |

|

Welded Standard |

AISI 1340 Modified |

All |

65 |

95 |

235 (max) |

18 |

30 |

|

Welded NS-1 |

AISI 4140H Modified |

All |

120 |

140 |

285 to 340 |

13 |

40 |

|

Welded Standard |

AISI 4140H Modified |

Above 7 1/4” |

120 |

140 |

285 to 340 |

13 |

40 |

|

Standard welded |

AISI 4140H Modified |

Up to 7 1/4” |

100 |

135 |

285 to 340 |

13 |

40 |

|

HWDP-110 HW MS |

ASCOWELL C |

Above 6 3/4” |

110 |

140 |

285 to 340 |

13 |

0 |

|

HWDP-110 HW MS |

ASCOWELL C |

Up to 6 3/4” |

100 |

135 |

285 to 340 |

13 |

55 |

|

HWDP-65 HW MS (tool joint) |

ASCOWELL C |

Above 6 3/4” |

110 |

140 |

285 to 340 |

13 |

55 |

|

HWDP-65 HW MS (tool joint) |

ASCOWELL C |

Up to 6 3/4” |

100 |

135 |

285 to 340 |

13 |

55 |

|

HWDP-65 HW MS |

AISI 1340 Modified |

All |

65 |

95 |

235 (max) |

18 |

30 |