ASTM A778 Steel Pipe

This specification covers straight seam and spiral butt seam welded unannealed austenitic stainless steel tubular products intended for low and moderate temperatures and corrosive service where treatment is not necessary for corrosion resistance. The tubular products shall be made from flat-rolled steel sheet, coil, or plate by a shielded arc-welding process.

Our Steel is a recognized supplier and distributor of ASTM A778 Austenitic Stainless Steel Tubes, which has a number of great attributes to provide like durability, high strength, rust proof, and so on. Superior grade of steel and higher technology is integrated in the manufacturing of these tubes. We offer these products to exceptional surface finish for an outstanding look and outstanding resistance to corrosion. Presented ASTM A778 Welded Tubes is manufactured by our reliable experts by using best grade of stainless steel. To suit the varied requirements of the customers, we offer these tubes in dissimilar sizes, specifications and grades. Clientele can get these products from us in different shapes like rectangular / oval / round / square and other related profiles parts according to their requirements. So as to strengthen our position, we are productively offering an extensive and quality of assured range of these tubes. Supported by our huge industrial know-how, we bring forward these Tubes to our respected customers.

This steel pipe is manufactured by using premium quality of material and progressive technology in tandem to collectively verified standards. The steel pipe presented by us is inspected in terms of quality prior to offering to our clientele. These ASME SA 778 Tubes offer a number of outstanding features like Resistant against rust, Durability, Robustness, Non-corrosive, High tensile strength, Fine finish, Reliable, Resistance against abrasion, Perfect finish, Robust construction, Highly durable, High resistance, Long life, Cost effective, Easy to install, Durable, High strength, Can endure soaring pressure and so on.

This specification covers welded unannealed tubular products 3 in. (75 mm) through 48 inch. (1200 mm) in outside diameter and in nominal wall thicknesses of 0.062 in. (1.5 mm) through 0.500 in. (12.5 mm) produced to this specification. Tubular products having other diameters, or wall thickness, or both may be furnished provided it complies with all other requirements of this specification.

|

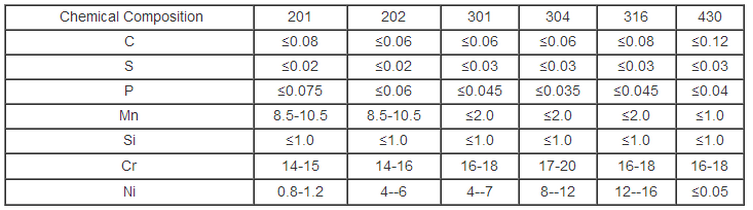

Chemical Composition(%) |

|||||||||||

|

Grade |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Mo |

N |

Cu |

|

|

201 |

≤0.15 |

≤0.75 |

5.5~7.5 |

≤0.060 |

≤0.03 |

16.00~18.00 |

3.5~5.5 |

- |

- |

0.08 |

1.5 |

|

202 |

≤0.15 |

≤1.00 |

7.5~10.00 |

≤0.060 |

≤0.03 |

17.00~19.00 |

4.0~6.0 |

- |

≤0.25 |

||

|

301 |

≤0.15 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.03 |

16.00~18.00 |

6.00~8.00 |

- |

|||

|

302 |

≤0.15 |

≤1.00 |

≤2.00 |

≤0.035 |

≤0.03 |

17.00~19.00 |

8.00~10.00 |

- |

|||

|

304 |

≤0.07 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.03 |

18.00~20.00 |

8.00~10.50 |

- |

|||

|

304L |

≤0.030 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.03 |

18.00~20.00 |

9.00~13.00 |

- |

|||

|

310S |

≤0.08 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.03 |

24.00~26.00 |

19.00~22.00 |

- |

|||

|

316 |

≤0.08 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.03 |

16.00~18.00 |

10.00~14.00 |

2.00~3.00 |

|||

|

316L |

≤0.03 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.03 |

16.00~18.00 |

12.00~15.00 |

2.00~3.00 |

|||

|

321 |

≤0.08 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.03 |

17.00~19.00 |

9.00~13.00 |

- |

|||

|

430 |

≤0.12 |

≤0.75 |

≤1.00 |

≤0.040 |

≤0.03 |

16.00~18.00 |

- |

||||

|

2205 |

≤0.03 |

≤1.00 |

≤2.00 |

≤0.030 |

≤0.015 |

22.00~23.00 |

4.5~6.5 |

2.5~3.5 |

|||

|

2507 |

≤0.03 |

≤0.08 |

≤1.20 |

≤0.035 |

≤0.015 |

24.00~26.00 |

6.00~8.00 |

3.0~5.0 |

|||

|

904L |

≤0.02 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.035 |

19.00~23.00 |

23.00~28.00 |

4.0~5.0 |

1.0~2.0 |

||

|

INCONEL 028 |

≤0.03 |

≤1.00 |

≤2.50 |

≤0.030 |

≤0.030 |

≤28.0 |

≤34.0 |

≤4.0 |

≤1.4 |

||

|

MONEL 400 |

≤0.30 |

≤0.5 |

≤2.00 |

- |

≤0.024 |

- |

≥63.0 |

- |

≤34.0 |

||

|

INCONEL 800 |

≤0.10 |

≤1.00 |

≤1.50 |

- |

≤0.015 |

≤23.0 |

≤35 |

4.0~5.0 |

- |

≤0.75 |

Ti≤0.6 Al≤0.6 |

Brushed. Matte. Polishing. Mirror 8K. Plated rose gold. Black titanium gold. Champagne gold. Bronze, etc