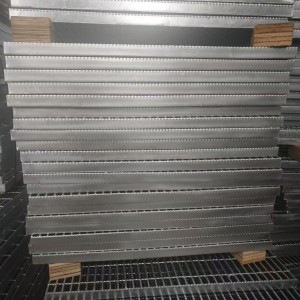

Steel Bar Grating

Steel bar grating is an open grid of metal bars in which the bearing bars running in one direction are spaced by rigid attachment to cross bars running perpendicular to them or by bent connecting bars extending between them, designed to support heavy loads with minimum weight. It is widely used as floors, mezzanines, stair treads, fencing, trench covers and maintenance platforms in factories, workshops, engine rooms, trolley channels, heavy load areas, boiler plant and heavy equipment areas etc.

Bar grating nomenclature

- Bearing Bars - Load carrying, span of grating

- Cross Bars - Connecting bars, runs along width of grating

- Finish - Coating applied-painted black, galvanized

- Serrated - Notching process for non-slip surface

- Widths - Overall dimension measured perpendicular to bearing bars

- Span - Distance running along direction of bearing bars

- Banding - Bar of the same size as bearing bar used to close open ends

- Kick Plate - Flat bar welded to outer edge with projection above grating

Technology

Welded galvanized grating: The cross bars are welded onto bearing bars with the high pressure resistance welding machine and then cutting, banding, surface treatment.

Press-locked galvanized grating: The cross bars are pressure locked onto the bearing bars with grooving and then welding and hot dipped galvanizing.

Applications

Galvanised gratings are designed and manufactured for various industrial and civil constructions in city roads, gardens, yards, airports, railways and industrial engineering.

Hot dip galvanised steel grating is the best choice for steel platforms in airports. Grating with 30 × 3 mm bearing bars with 30 mm spacing and 50 mm or 100 mm cross bars is suitable.

Steel grating, with its robust design and spanning capability, is very strong and safe for supporting floors and elevated walkways. It can be used for ceiling, interior decoration, platform aisle, ventilation window, (wells), advertising plaque and other construction.

Widely used in petrochemical industry, power plants, waterworks, sewage treatment plants, municipal works, sanitation projects in areas such as platforms, corridors, bridge, trench cover, covers, ladders, fences, rails and so on.