Drill Collars

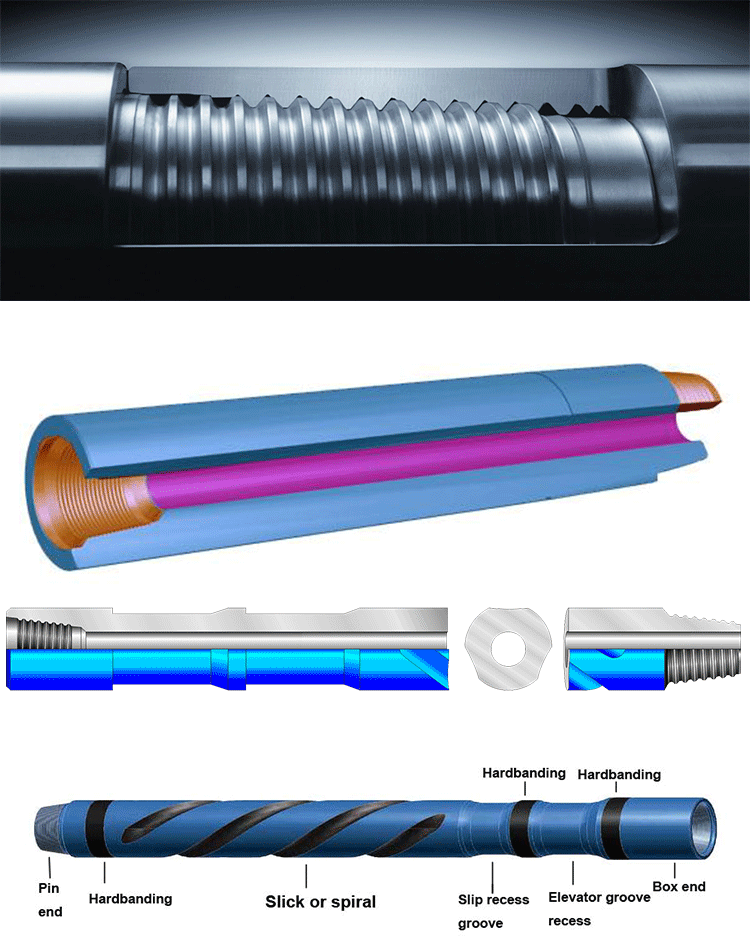

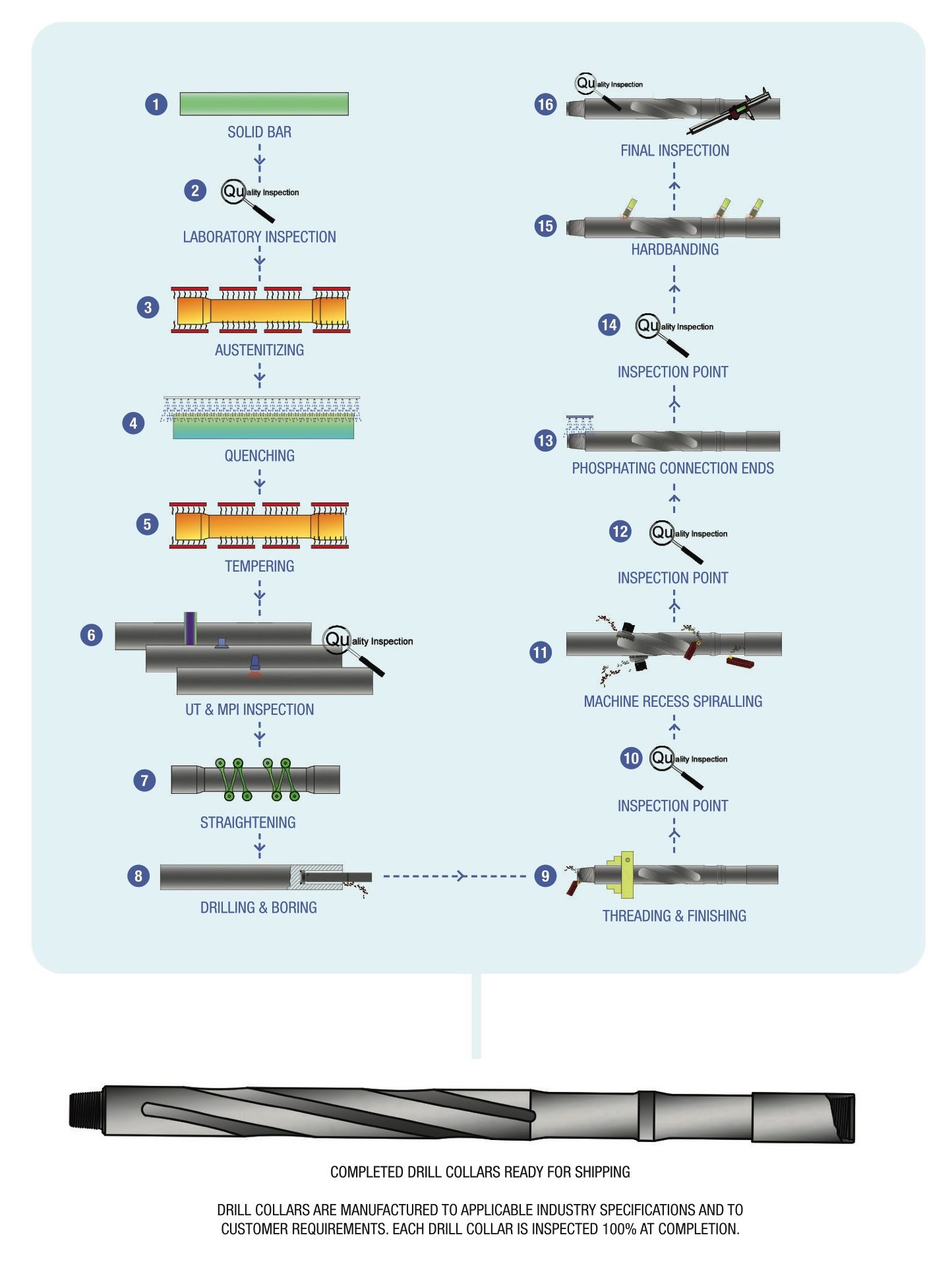

Drill collar as one component of a drill string is extremely industrial tubulars used to drill into ground to provides weight on bit for drilling. It is used to conjunction with drill pipe. There are slick and spiral grooved types mainly. Our manufacturing process is certified to API spec 7-1. The drill collar is made of AISI 4145 H or 4145 H Modified alloy steel. Bores are trepanned from one direction with no mismatch. All drill collars are heat-treated with hardness within 285 to 341 BHN, which are guaranteed one inch below the surface of the pipe.

Non-magnetic drill collars offer strength and hardness while preventing magnetic interference that may impair accuracy of magnetic surveys. It is manufactured from special steel material with low permeability, high mechanical properties and superior resistance to corrosion cracking.

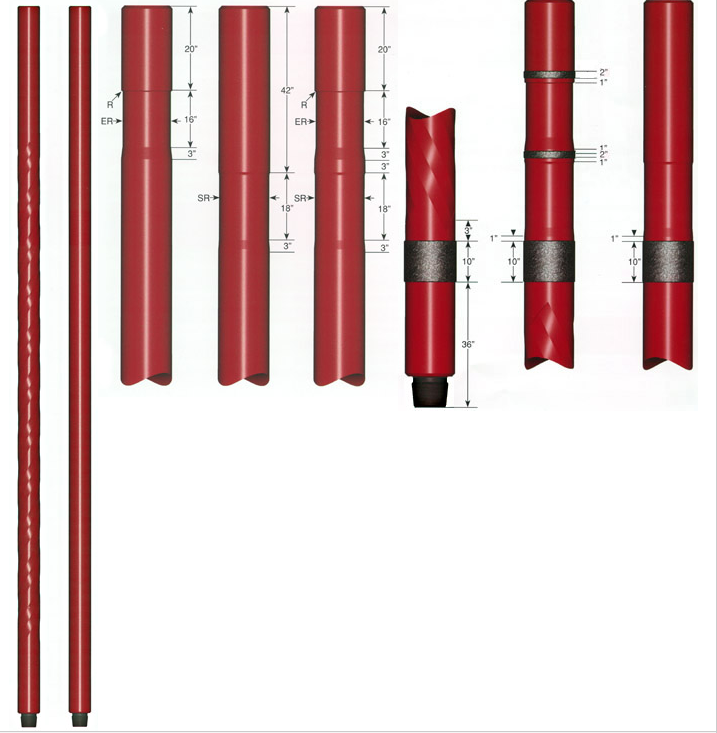

We supply slick drill collars, spiral drill collars and non-magnetic drill collars; their sizes are from 3-1/8 to 11 inches. Besides the drill collars in the table below, we can supply other drill collars at customers’ request.

|

Item |

Name |

Spiral or Slick |

O.D |

I.D |

Tool joint |

Bevel diameter in |

Material |

Overall length |

|

|

in |

in |

Connection |

ft |

||||||

| 1 | Drill collar | Slick or Spiral | 3.1/8 | 1.1/4 | NC26 | 2.3/8″IF | 3 | 4145H | 30 or 31 |

| 2 | Drill collar | Slick or Spiral | 3.1/2 | 1.1/2 | NC26 | 2.3/8″IF | 4145H | 30 or 31 | |

| 3 | Drill collar | Slick or Spiral | 4.1/8 | 2 | NC31-41 | 2.7/8″IF | 3.61/64 | 4145H | 30 or 31 |

| 4 | Drill collar | Slick or Spiral | 4.3/4 | 2 | NC35-47 | 4.33/64 | 4145H | 30 or 31 | |

| 5 | Drill collar | Slick or Spiral | 5 | 2.1/4 | NC38-50 | 3.1/2″IF | 4.49/64 | 4145H | 30 or 31 |

| 6 | Drill collar | Slick or Spiral | 6 | 2.1/4 | NC44-60 | 5.11/16 | 4145H | 30 or 31 | |

| 7 | Drill collar | Slick or Spiral | 6 | 2.13/16 | NC44-60 | 5.11/16 | 4145H | 30 or 31 | |

| 8 | Drill collar | Slick or Spiral | 6.1/4 | 2.1/4 | NC44-62 | 5.7/8 | 4145H | 30 or 31 | |

| 9 | Drill collar | Slick or Spiral | 6.1/4 | 2.13/16 | NC46-62 | 4″IF | 5.29/32 | 4145H | 30 or 31 |

| 10 | Drill collar | Slick or Spiral | 6.1/2 | 2.1/4 | NC46-65 | 4″IF | 6.3/32 | 4145H | 30 or 31 |

| 11 | Drill collar | Slick or Spiral | 6.1/2 | 2.13/16 | NC46-65 | 4″IF | 6.3/32 | 4145H | 30 or 31 |

| 12 | Drill collar | Slick or Spiral | 6.3/4 | 2.1/4 | NC46-67 | 4″IF | 6.9/32 | 4145H | 30 or 31 |

| 13 | Drill collar | Slick or Spiral | 7 | 2.1/4 | NC50-70 | 4.1/2″IF | 6.31/64 | 4145H | 30 or 31 |

| 14 | Drill collar | Slick or Spiral | 7 | 2.13/16 | NC50-70 | 4.1/2″IF | 6.31/64 | 4145H | 30 or 31 |

| 15 | Drill collar | Slick or Spiral | 7.1/4 | 2.13/16 | NC50-72 | 4.1/2″IF | 6.43/64 | 4145H | 30 or 31 |

| 16 | Drill collar | Slick or Spiral | 7.3/4 | 2.13/16 | NC56-77 | 7.19/64 | 4145H | 30 or 31 | |

| 17 | Drill collar | Slick or Spiral | 8 | 2.13/16 | NC56-80 | 7.31/64 | 4145H | 30 or 31 | |

| 18 | Drill collar | Slick or Spiral | 8.1/4 | 2.13/16 | 6.5/8″REG | 7.45/64 | 4145H | 30 or 31 | |

| 19 | Drill collar | Slick or Spiral | 9 | 2.13/16 | NC61-90 | 8.3/8 | 4145H | 30 or 31 | |

| 20 | Drill collar | Slick or Spiral | 9.1/2 | 3 | 7.5/8″REG | 8.13/16 | 4145H | 30 or 31 | |

| 21 | Drill collar | Slick or Spiral | 9.3/4 | 3 | NC70-97 | 9.5/32 | 4145H | 30 or 31 | |

| 22 | Drill collar | Slick or Spiral | 10 | 3 | NC70-100 | 9.11/32 | 4145H | 30 or 31 | |

| 23 | Drill collar | Slick or Spiral | 11 | 3 | 8.5/8″REG | 10.1/2 | 4145H | 30 or 31 | |

| Note: | If the cliente has any special requerimente, for example compound,cold rolling,make and break,hard banding (ARNCO 100XT ARNCO 300XT etc), internal coating (TK34 TK34PTC2000, etc),Stress- Relief Pin, Bored Back Box,Elevator Recess, slip Recess please feel free to contact us. | ||||||||

| Non-Magetic Drill Collar | ||

|

Grade |

Minimum Tensile Strength |

|

|

psi |

Mpa |

|

|

1 |

90000 |

621 |

|

2 |

9000 |

621 |

|

3 |

115000 |

793 |

| **Non-magetic drill collar can be customized as per customer’s design. The size please refer to the sizes of drill collar. | ||

| Spiral Drill Collar | |||||||||

|

OD (in) |

4 3/4 |

6 1/4 |

6 3/4 |

7 1/4 |

7 1/2 |

8 |

9 1/2 |

10 |

11 |

|

Depth of Cut (in) |

7/32 ±1/32 |

9/32 ±1/16 |

5/16 ±1/16 |

11/32 ±1/16 |

11/32 ±1/16 |

3/8 ±1/16 |

13/32 ±3/32 |

7/16 ±3/32 |

15/32 ±3/32 |

|

Spiral Pitch (in) |

38 ±1 |

42 ±1 |

46 ±1 |

64 ±1 |

64 ±1 |

68 ±1 |

72 ±1 |

76 ±1 |

80 ±1 |

| ** Drill collar can be customized as per customer’s design. | |||||||||

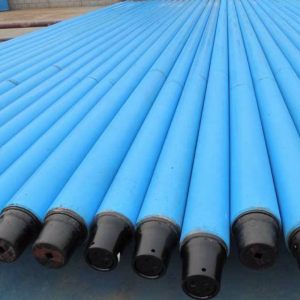

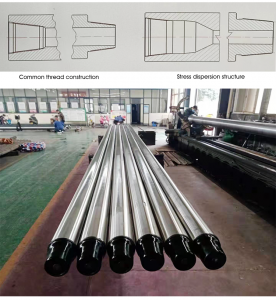

Drill collars are an integral heavy duty joint that are constructed from a solid bar of AISI 4145H modified alloy steel.? Our standard drill collars are supplied with an “as rolled” surface finish condition.? All standard bars receive heat-treatment that provides them with the necessary mechanical properties.

The bars are then trepanned and drifted.? All of our drill collars are manufactured in

accordance with API spec 7, Q1 and recommended practice 7G, as applicable.

Standard Sizes, Bores, and Connections

| Drill Collar Conn. Size & Type |

Min. OD |

Bore | Length | Bending Strength Ratio*** |

Drill Collar Wt. |

| (in.) | (in.) | (ft.) | (lb.) | ||

| NC 26 (2-3/8 IF) |

3-1/2 |

1-1/2 | 30 | 2.42:1 | 801 |

| NC 31 (2-7/8 IF) | 4-1/8 | 2 | 30 | 2.43:1 | 1041 |

| NC 38 (3-1/2 IF) | 4-3/4 | 2-1/4 | 31 | 1.85:1 | 1451 |

| NC 38 (3-1/2 IF) | 5 | 2-1/4 | 31 | 2.38:1 | 1652 |

| NC 44 | 6 | 2-1/4 | 31 | 2.49:1 | 2561 |

| NC 44 | 6 | 2-13/16 | 31 | 2.84:1 | 2353 |

| NC 44 | 6-1/4 | 2-1/4 | 31 | 2.91:1 | 2806 |

| NC 46 (4 IF) | 6-1/4 | 2-13/16 | 31 | 2.63:1 | 2598 |

| NC 46 (4 IF) | 6-1/2 | 2-1/4 | 31 | 2.76:1 | 3085 |

| NC 46 (4 IF) | 6-1/2 | 2-13/16 | 31 | 3.05:1 | 2877 |

| NC 46 (4 IF) | 6-3/4 | 2-1/4 | 31 | 3.18:1 | 3364 |

| NC 50 (4-1/2 IF) | 7 | 2-1/4 | 31 | 2.54:1 | 3643 |

| NC 50 (4-1/2 IF) | 7 | 2-13/16 | 31 | 2.73:1 | 3434 |

| NC 50 (4-1/2 IF) | 7-1/4 | 2-13/16 | 31 | 3.12:1 | 3714 |

| NC 56 | 8 | 2-13/16 | 31 | 3.02:1 | 4675 |

| 6-5/8 REG. | 8 | 2-13/16 | 31 | 2.60:1 | 4675 |

| 6-5/8 REG. | 8-1/4 | 2-13/16 | 31 | 2.93:1 | 5016 |

| 7-5/8 REG. | 9-1/2 | 3 | 31 | 2.81:1 | 6727 |

| 7-5/8 REG.** | 9-3/4 | 3 | 31 | 3.09:1 | 7130 |

| 8-5/8 REG.** | 11 | 3 | 30 | 2.78:1 | 8970 |

| ** Low torque face *** Ratio of box to pin section modulus – See API RP7G for details Note: Other sizes and connections are available as well as any other optional features listed |

|||||

| Mechanical Property | ||||||

| TTT |

Yield strength 0.2Mpa |

Tensile strength b Mpa |

Elongation 4% |

Hardness(Brinell) |

IMPACT VALUE(CHAPPY-V) |

|

| mm |

in inch |

|||||

| 79.4-171.4 |

3 1/8-6 3/4 |

≥ 758 |

≥ 965 |

≥ 13 |

285-341 |

≥ 54 |

| 177.8-279.4 |

7-11 |

≥ 689 |

||||