Pipe Coating(Pipeline Coating)

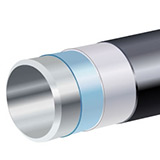

(1)3LPE

Three Layer Polyethylene (3LPE) is a multi-layer coating consisting of three functional components: a high-performance fusion-bonded epoxy resin (FBE), followed by a copolymer adhesive and a polyethylene outer layer. Provides rugged protection. The 3LPE system provides excellent pipe protection for small and large diameter pipes with moderate operating temperatures

| Product: | 3LPE Coated Pipe |

| Application: | Used for natural gas, petroleum, water & sewage, and pipe systems |

| Standard: | DIN30670 |

| Size: | DN50-DN2200 |

| End: | Plain End/Bevelled End, Burr Removed |

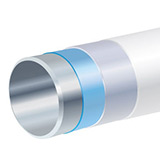

(2)3LPP

Three Layer Polypropylene (3LPP) consists of a high performance FBE layer, a copolymer adhesive and a polypropylene outer layer to provide the toughest and most durable pipe coating solution.

| Product: | 3LPP Coated Pipe |

| Application: | Used for natural gas, petroleum, water & sewage, and pipe systems |

| Standard: | DIN30678 |

| Size: | DN50-DN2200 |

| End: | Plain End/Bevelled End, Burr Removed |

(3)FBE

Fusion-Bonded Epoxy (FBE) is a high performance corrosion resistant coating that provides excellent protection for small and large diameter pipes at moderate operating temperatures.

| Product: | FBE (Fusion Bond Epoxy) Coated Pipe, 3PE Coated Pipe |

| Application: | Used for natural gas, petroleum, water & sewage, and pipe systems |

| Standard: | DIN30670 |

| Size: | DN50-DN2200 |

| End: | Plain End/Bevelled End, Burr Removed |