Structural Steel Pipe

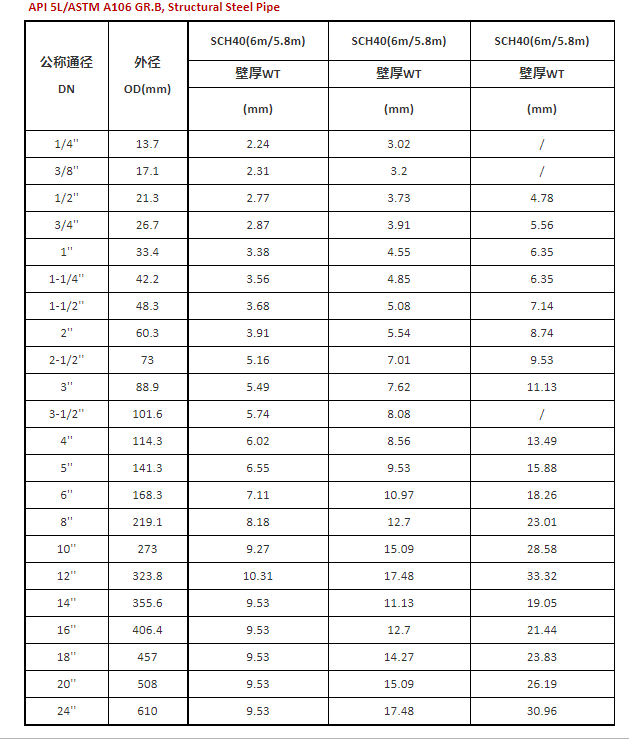

The structure steel pipe has hot - rolled seamless steel tube and welded steel tube.The seamless steel tube for structure is divided into two types according to the provisions of "seamless steel tube for structure" (GB/ t8162-2008) : hot rolling (extrusion, expansion) and cold drawing (rolling).The outer diameter of hot-rolled steel pipe is 32-630mm and the wall thickness is 2.5-75mm. The outer diameter of cold-drawn steel pipe is 5-200mm and the wall thickness is 2.5-12mm. Welded steel pipe is made of steel plate or steel strip after crimping and forming, which can be divided into straight welded steel pipe and spiral welded steel pipe.The outer diameter and wall thickness of the direct-welded steel pipe are 5-508mm and 0.5-12.7mm respectively, which shall comply with the provisions of GB/ t3793-2008.The welded steel pipe for low-pressure fluid transportation is also called common welded pipe, commonly known as clark pipe. The specification is expressed in mm of nominal diameter, which should comply with the provisions of GB/ t3091-2008 for low-pressure fluid transportation.

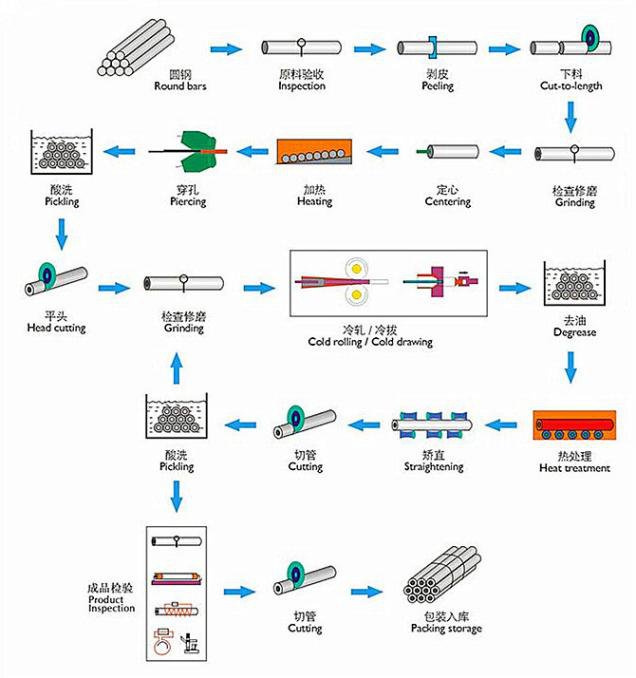

Manufacturing Process

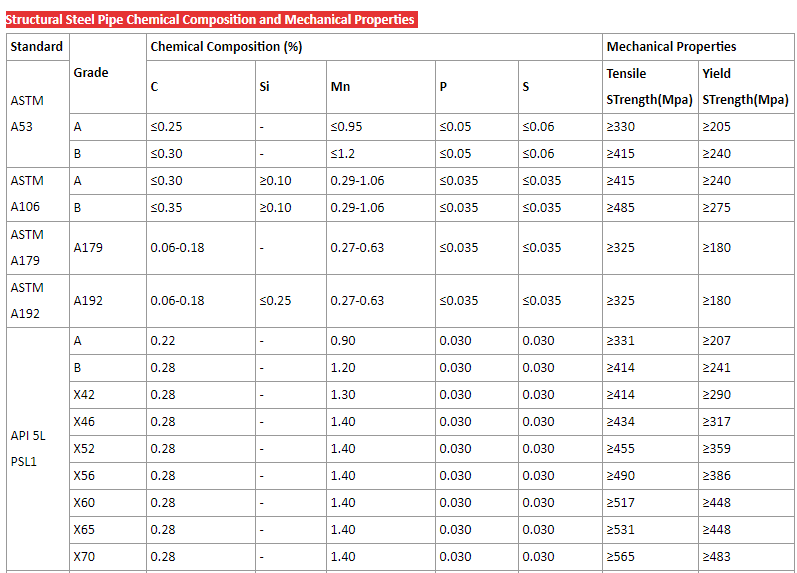

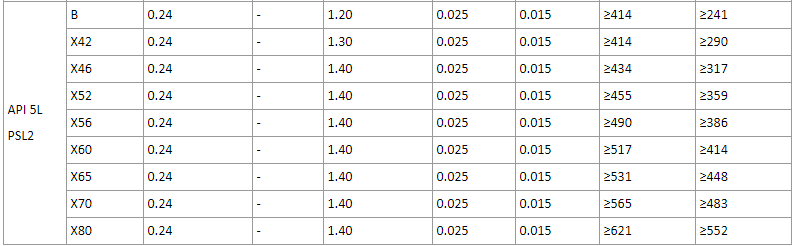

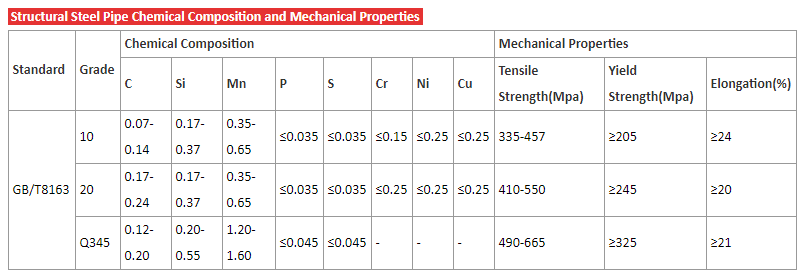

Chemical Composition

| Grade | C | Mn | P | S | Si | Cr | Mo |

| 1010 | 0.08-0.13 | 0.30-0.60 | ≤0.04 | ≤0.05 | - | - | - |

| 1020 | 0.08-0.23 | 0.30-0.60 | ≤0.04 | ≤0.05 | - | - | - |

| 1045 | 0.43-0.50 | 0.60-0.90 | ≤0.04 | ≤0.05 | - | - | - |

| 4130 | 0.28-0.33 | 0.40-0.60 | ≤0.04 | ≤0.05 | 0.15-0.35 | 0.80-1.10 | 0.15-0.25 |

| 4140 | 0.38-0.43 | 0.75-1.00 | ≤0.04 | ≤0.05 | 0.15-0.35 | 0.80-1.10 | 0.15-0.25 |

Mechanical Properties

| Grade | Condition | Tensile strength Mpa(min) | Yield stength Mpa(min) | Elongation %(min) |

| 1020 | CW | 414 | 483 | 5 |

| SR | 345 | 448 | 10 | |

| A | 193 | 331 | 30 | |

| N | 234 | 379 | 22 | |

| 1025 | CW | 448 | 517 | 5 |

| SR | 379 | 483 | 8 | |

| A | 207 | 365 | 25 | |

| N | 248 | 379 | 22 | |

| 4130 | SR | 586 | 724 | 10 |

| A | 379 | 517 | 30 | |

| N | 414 | 621 | 20 | |

| 4140 | SR | 689 | 855 | 10 |

| A | 414 | 552 | 25 | |

| N | 621 | 855 | 20 |

Annealed, Normalized, Stress relieved, Cold finished, Quenched and Tempered