Pipa Baja Struktural

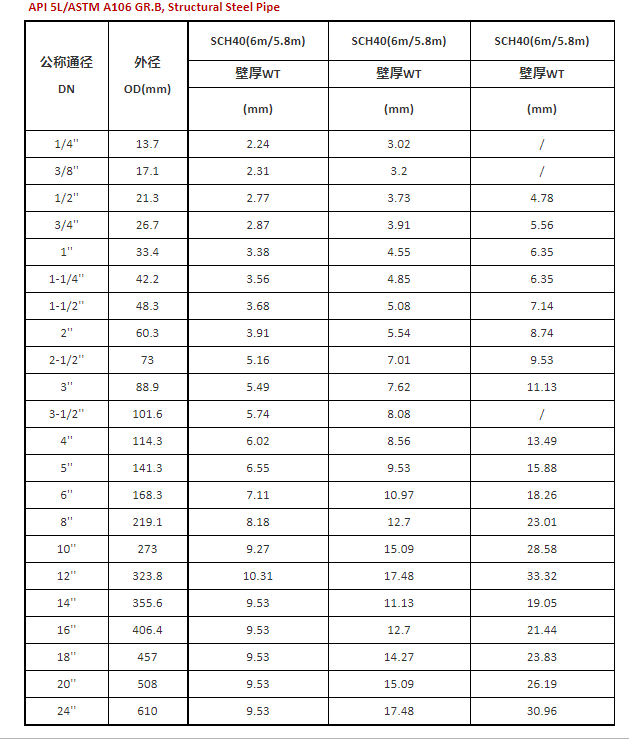

Pipa baja struktur memiliki tabung baja mulus canai panas dan tabung baja las. Tabung baja mulus untuk struktur dibagi menjadi dua jenis sesuai dengan ketentuan "tabung baja mulus untuk struktur" (GB/ t8162-2008): hot rolling ( ekstrusi, ekspansi) dan penarikan dingin (penggulungan). Diameter luar pipa baja canai panas adalah 32-630mm dan ketebalan dinding 2,5-75mm.Diameter luar pipa baja tarik dingin adalah 5-200mm dan ketebalan dinding 2,5-12mm.Pipa baja las terbuat dari pelat baja atau strip baja setelah dikerutkan dan dibentuk, yang dapat dibagi menjadi pipa baja las lurus dan pipa baja las spiral. Diameter luar dan tebal dinding pipa baja las langsung adalah 5-508mm dan 0,5 -12.7mm masing-masing, yang harus memenuhi ketentuan GB/t3793-2008.Pipa baja yang dilas untuk pengangkutan fluida bertekanan rendah disebut juga pipa las biasa, biasa disebut pipa clark.Spesifikasinya dinyatakan dalam mm diameter nominal, yang harus memenuhi ketentuan GB/t3091-2008 untuk pengangkutan fluida bertekanan rendah.

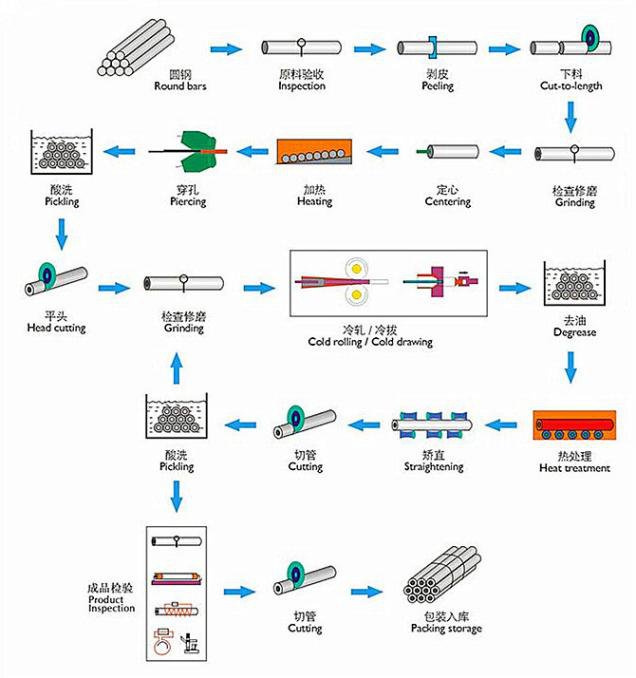

Proses Manufaktur

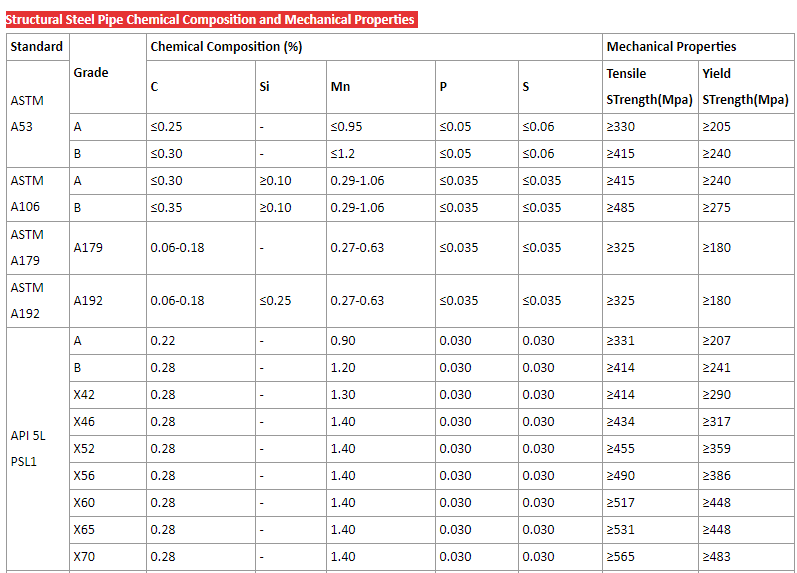

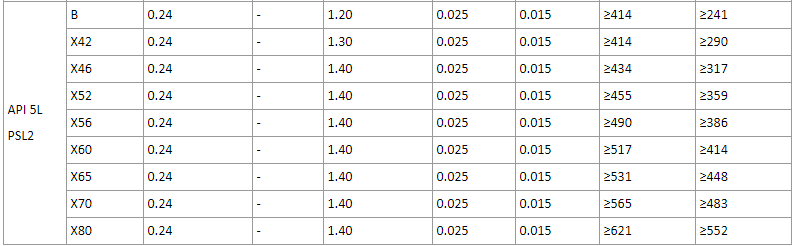

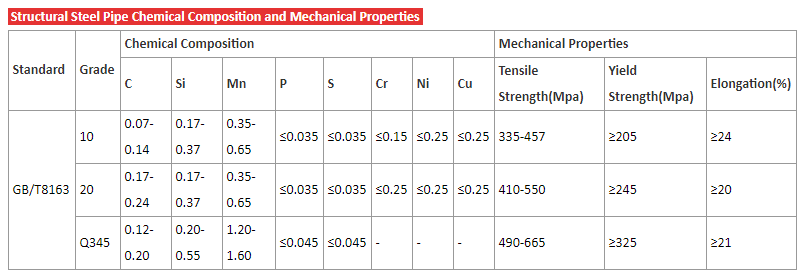

Komposisi kimia

| Nilai | C | Mn | P | S | Si | Cr | Mo |

| 1010 | 0,08-0,13 | 0,30-0,60 | ≤0,04 | ≤0,05 | - | - | - |

| 1020 | 0,08-0,23 | 0,30-0,60 | ≤0,04 | ≤0,05 | - | - | - |

| 1045 | 0,43-0,50 | 0,60-0,90 | ≤0,04 | ≤0,05 | - | - | - |

| 4130 | 0,28-0,33 | 0,40-0,60 | ≤0,04 | ≤0,05 | 0,15-0,35 | 0,80-1,10 | 0,15-0,25 |

| 4140 | 0,38-0,43 | 0,75-1,00 | ≤0,04 | ≤0,05 | 0,15-0,35 | 0,80-1,10 | 0,15-0,25 |

Peralatan mekanis

| Nilai | Kondisi | Kekuatan tarik Mpa(min) | Kekuatan hasil Mpa(min) | Perpanjangan %(mnt) |

| 1020 | CW | 414 | 483 | 5 |

| SR | 345 | 448 | 10 | |

| A | 193 | 331 | 30 | |

| N | 234 | 379 | 22 | |

| 1025 | CW | 448 | 517 | 5 |

| SR | 379 | 483 | 8 | |

| A | 207 | 365 | 25 | |

| N | 248 | 379 | 22 | |

| 4130 | SR | 586 | 724 | 10 |

| A | 379 | 517 | 30 | |

| N | 414 | 621 | 20 | |

| 4140 | SR | 689 | 855 | 10 |

| A | 414 | 552 | 25 | |

| N | 621 | 855 | 20 |

Anil, Normalisasi, Menghilangkan Stres, Selesai Dingin, Dipadamkan, dan Ditempa