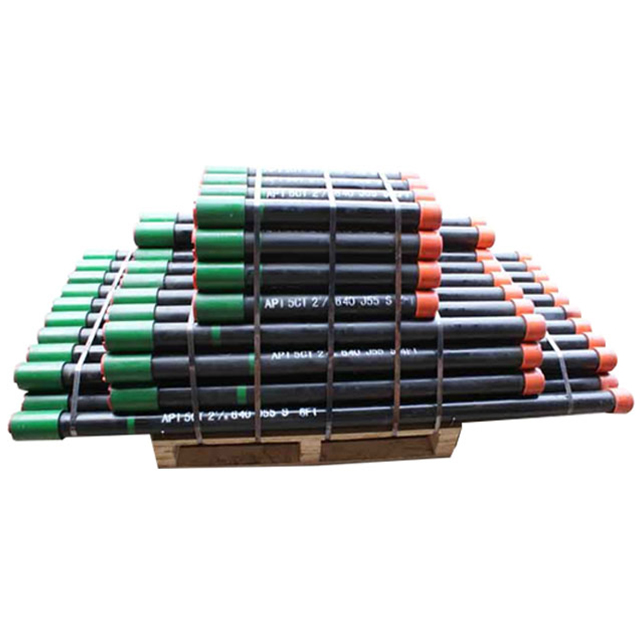

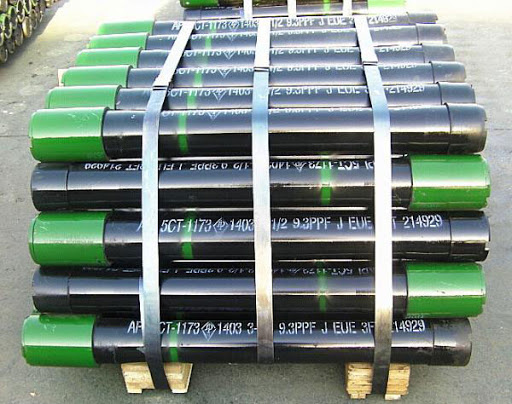

Pup Joint

A pup joint is a casing or tubing of length shorter than Range 1 with the same thread connection, used to adjust the length of tubular strings to its exact requirement.

Pup Joints are manufactured from AISI 4145H or 4140H-modified alloy, heat-treated to a Brinell Hardness range of 285-341 with a Charpy “V” notch minimum impact strength of 40 ft/lb at 70° F and one inch below the surface. Pup Joints are heat-treated to 110,000 PSI minimum yield. All connections are phosphate coated to impede galling during initial make-up.

They are available in standard lengths of 5’, 10’, 15’ and 20’ with other configurations upon request.

Integral Pup Joints dedicated to Sour Service applications are available. PJ -110 PUP S are Sour Service Pup Joint using ASCOWELL C material providing improved resistance to Sulfide Stress Cracking with high yield strength.

We can offers a wide range drill string products and accessories with standard API or proprietary high performance

connections to meet the most demanding drilling requirements.

| Tubing Pup Joint Specifications | |

| Outside Diameter | 1.05 ~ 4-1/2 in (26.67 ~ 114.3 mm) nominal size OD |

| Weight | Standard or Heavy Wall |

| Length | 2, 3, 4, 5, 6, 8, 10, 12 ft (with other lengths available upon request) |

| Grade | H40, J55, L80, N80/Q, C90, T95, P110 |

| Connection | EUE, NUE |

| Standard | API 5CT, API 5B |

| Casing Pup Joint Specifications | |

| Outside Diameter | 4-1/2 ~ 20 in (114.3 ~ 508 mm) nominal size OD |

| Weight | Standard or Heavy Wall |

| Length | 2, 3, 4, 5, 6, 8, 10, 12, 14, 16, 18, 20 ft (with other lengths available upon request) |

| Grade | H40, J55, K55, L80, N80/Q, C90, T95, P110, Q125 |

| Connection | BTC, STC, LTC |

| Standard | API 5CT, API 5B |

All pump joints are made from modified alloy steel heat-treated to a Brinell Hardness range of 285–341 with a Charpy V-Notch minimum impact strength of 40 ft-lbs at 70°F guaranteed to one inch below the surface Connections can be cold rolled after machining, if requested All connections are phos-coated to prevent galling during initial make-up

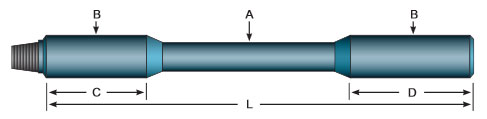

Nominal size: 3 1/2”OD ~ 6~ 5/8” OD, Length: 5′, 10′, 15′, 20′

|

Nominal Size – A (in) |

Tool Joint OD – B (in) |

Tool Joint ID (in) |

TJ Pin Tong – C (in) |

TJ Box Tong – D (in) |

Connection |

|

2-3/8 |

3-3/8 |

1-1/2 |

9 |

12 |

NC26 |

|

2-7/8 |

4-1/8 |

2-1/8 |

9 |

11 |

NC31 |

|

3-1/2 |

4-3/4 |

2-9/16 |

10 |

12-1/2 |

NC38 |

|

3-1/2 |

5 |

2-1/8 |

10 |

12-1/2 |

NC38 |

|

4 |

5-1/4 |

2-11/16 |

9 |

12 |

NC40 |

|

4-1/2 |

6-1/4 |

3 |

9 |

12 |

NC46 |

|

5 |

6-1/2 |

3-1/4 |

9 |

12 |

NC50 |

|

5 |

6-5/8 |

2-3/4 |

9 |

12 |

NC50 |

|

5 |

6-5/8 |

3-1/4 |

9 |

12 |

NC50 |

|

5-1/2 |

7-1/4 |

3-1/2 |

8 |

10 |

5-1/2 FH |

|

5-1/2 |

7-1/2 |

3-1/2 |

10 |

12 |

5-1/2 FH |

|

6-5/8 |

8-1/2 |

4-1/4 |

8 |

10 |

6-5/8 FH |

|

6-5/8 |

8 |

5 |

8 |

10 |

6-5/8 FH |

Sour Service grades and equivalent to G-105 and S-135 are available upon request

Length L(ft): 5; 10; 15; 20

Other configurations are available upon request

All hardbanding and coating options available upon request.

API Spec 5CT – This Standard specifies the technical delivery conditions for steel pipes (casing, tubing and pup joints), coupling stock, coupling material and accessory material and establishes requirements for three Product Specification Levels (PSL-1, PSL-2, PSL-3). The requirements for PSL-1 are the basis of this Standard. The requirements that define different levels of standard technical requirements for PSL-2 and PSL-3, for all Grades except H-40, L-80 9Cr and C110, are contained in Annex H.

Chemical Composition

| Standard | Grade | Chemical compositions(%) | |||||||||

| API SPEC 5CT | J55 | C | Si | Mn | P | S | Cr | Ni | Cu | Mo | V |

| K55 | 0.34~0.39 | 0.20~0.35 | 1.25~1.50 | ≤0.020 | ≤0.015 | ≤0.15 | ≤0.20 | ≤0.20 | / | / | |

| N80 | 0.34~0.38 | 0.20~0.35 | 1.45~1.70 | ≤0.020 | ≤0.015 | ≤0.15 | / | / | / | 0.11~0.16 | |

| L80 | 0.15~0.22 | ≤1.00 | 0.25~1.00 | ≤0.020 | ≤0.010 | 12.0~14.0 | ≤0.20 | ≤0.20 | / | / | |

| P110 | 0.26~0.395 | 0.17~0.37 | 0.40~0.70 | ≤0.020 | ≤0.010 | 0.80~1.10 | ≤0.20 | ≤0.20 | 0.15~0.25 | ≤0.08 | |

Mechanical properties

| Grade | Type | Total elongation under load (%) | Yield strength (min) | Yield strength (max) | Tensile strength min Mpa | Hardness Max (HRC) | Hardness Max (HBW) |

| J55 | - | 0.5 | 379 | 552 | 517 | - | - |

| K55 | - | 0.5 | 379 | 552 | 655 | - | - |

| N80 | 1 | 0.5 | 552 | 758 | 689 | - | - |

| N80 | Q | 0.5 | 552 | 758 | 689 | - | - |

| L80 | 1 | 0.5 | 552 | 655 | 655 | 23 | 241 |

| L80 | 9Cr | 0.5 | 552 | 655 | 655 | 23 | 241 |

| L80 | 13Cr | 0.5 | 552 | 655 | 655 | 23 | 241 |

| C90 | - | 0.5 | 621 | 724 | 689 | 25.4 | 255 |

| C95 | - | 0.5 | 655 | 758 | 724 | - | - |

| T95 | - | 0.5 | 655 | 758 | 724 | 25.4 | 255 |

| P110 | - | 0.6 | 758 | 965 | 862 | - | - |

| Q125 | All | 0.65 | 862 | 1034 | 931 | - | - |

The anti-corrosion of petroleum casing is mainly divided into three types:

- Brush the anti-corrosive coating on the outer wall.

- Brush anti-corrosion coating on the inner wall.

- Brush the anti-corrosive and cooling coating.

With the use of oil casings and pup joint in harsh oil extraction industries such as the polar and marine. It requires the material and structure of petroleum pup joint, and it must have good nodality, excellent physical properties, stable chemical properties, and a wide range of temperature adaptation. If the oil casing cannot be made, it should be coated with an anti-corrosive coating to help him cope with the harsh environment. The coating on the outer wall is used to reduce external corrosion, and the anti-corrosion coating on the inner wall is to reduce friction, reduce corrosion in the pipe, and increase the amount of oil transported. Anti-corrosive insulation coating is used to transport crude oil and fuel oil, and reduce the heat emitted from the pipeline to the soil.

The outer surface shall be coated (painted) and marked according to API 5CT standard, bundled with wooden cases, pallets, steel belts or other packaging as required by customers.