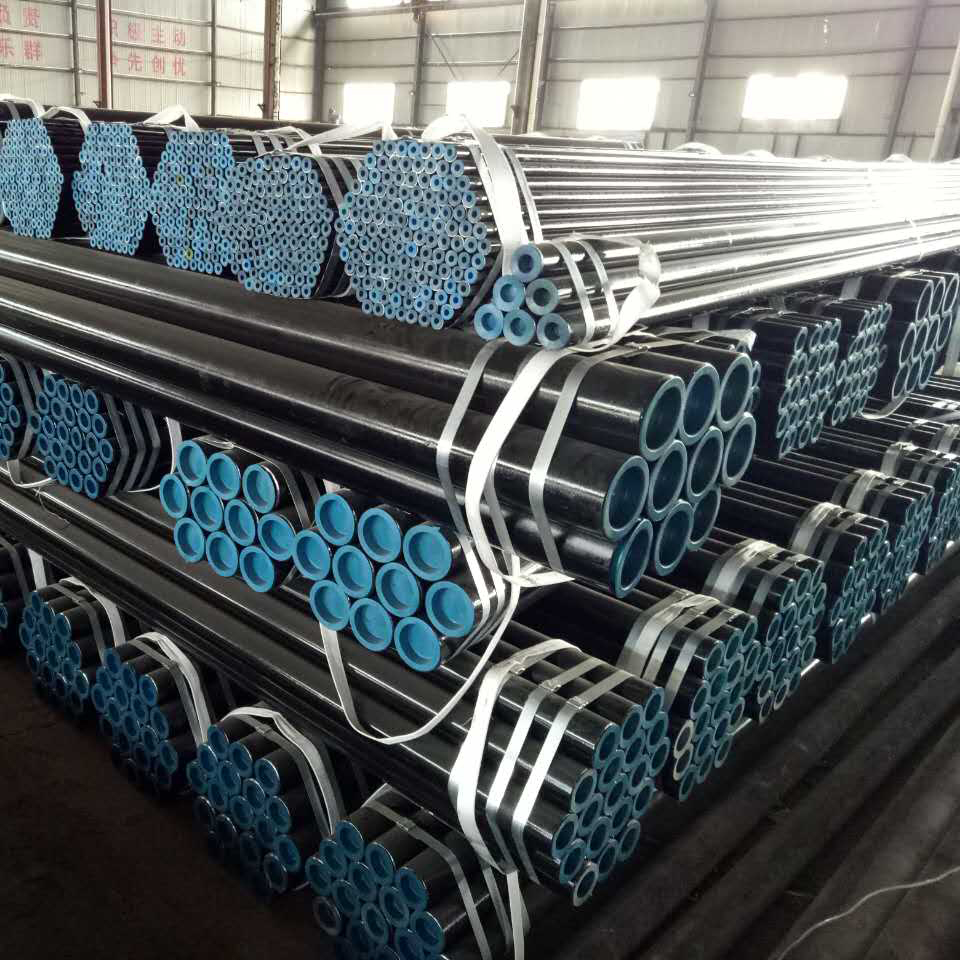

Bututu Mai Fadawa Mai zafi

Bututun ƙarfe mai faɗaɗa zafi yana da zafi mai faɗaɗa sumul bututu, wanda ba shi da ƙarancin yawa amma ƙaƙƙarfan bututun ƙarfe (bututu mara nauyi) ana iya magana da shi azaman faɗaɗa thermal.Hanyar jujjuyawar skew ko hanyar zane don faɗaɗa diamita na bututu.Karfe Pipe Thickening a cikin ɗan gajeren lokaci, na iya samar da rashin daidaito da na musamman na shambura tare da ƙananan samarwa da babban cigaba, abubuwan ci gaba na ƙasa da ƙasa.

Hot fadada bututu ne ta hanyar fadada diamita na bututu zuwa gama tafiyar matakai - thermal fadada tsari na samar da karfe bututu.Hot fadada bututu yawanci ana nufin zafi fadada sumul karfe bututu.

Ma'aunin Fasaha na Bututun Karfe Mai Faɗawa Mai zafi:

| Girman mara kyau | Waje | Ƙaunar bango mara kyau (mm) | |||||||||||||

| DN | NPS | OD(MM) | SCH | SCH | SCH | STD | SCH | SCH | XS | SCH | SCH | SCH | SCH | SCH | XXS |

| 200 250 300 | 8 1012 | 219.1 273.1 323.9 | 3.76 4.19 4.57 | 6.35 6.35 6.35 | 7.04 7.80 8.38 | 8.18 9.27 9.53 | 8.18 9.27 10.31 | 10.31 12.70 14.27 | 12.70 12.70 12.70 | 12.70 15.09 17.48 | 15.09 18.26 21.44 | 18.26 21.44 25.40 | 20.62 25.40 28.58 | 23.01 28.58 33.32 | 22.23 25.40 25.40 |

| 350 400 450 | 14 16 18 | 355.6 406.4 457.2 | 6.35 6.35 6.35 | 7.92 7.92 7.92 | 9.53 9.53 11.13 | 9.53 9.53 9.53 | 11.13 12.70 14.27 | 15.09 16.66 19.05 | 12.70 12.70 12.70 | 19.05 21.44 23.83 | 23.83 26.19 29.36 | 27.79 30.96 34.93 | 31.75 36.53 39.67 | 35.71 40.49 45.24 | -- |

| 500 550 600 | 2022 24 | 508 559 610 | 6.35 6.35 6.35 | 9.53 9.53 9.53 | 12.70 12.70 14.27 | 9.53 9.53 9.53 | 15.09 - 17.48 | 20.62 22.23 24.61 | 12.70 | 26.19 28.58 30.96 | 32.54 34.93 38.89 | 38.10 41.28 46.02 | 44.45 47.63 52.37 | 50.01 53.98 59.54 | -- |

| 500 550 600 | 2022 24 | 508 559 610 | 6.35 6.35 6.35 | 9.53 9.53 9.53 | 12.70 12.70 14.27 | 9.53 9.53 9.53 | 15.09 - 17.48 | 20.62 22.23 24.61 | 12.70 12.70 12.70 | 26.19 28.58 30.96 | 32.54 34.93 38.89 | 38.10 41.28 46.02 | 44.45 47.63 52.37 | 50.01 53.98 59.54 | -- |

| Farashin 660700750 | 2628 30 | 660 711 762 | 7.92 7.92 7.92 | 12.70 12.70 12.70 | - 15.88 15.88 | 9.53 9.53 9.53 | -- | -- | 12.70 12.70 12.70 | -- | -- | -- | -- | -- | -- |

| 800 850 900 | 32 34 36 | 813 864 914 | 7.92 7.92 7.92 | 12.70 12.70 12.70 | 15.88 15.88 15.88 | 9.53 9.53 9.53 | 17.48 17.48 19.05 | -- | 12.70 12.70 12.70 | -- | -- | -- | -- | -- | -- |

| Diamita na Waje (mm) / | SCH | SCH | SCH | STD | SCH | SCH | XS | SCH | SCH | SCH | SCH | SCH |

| 457 | 6.35 | 7.92 | 11.13 | 9.53 | 14.27 | 19.05 | 12.70 | 23.88 | 29.36 | 34.93 | 39.67 | 45.24 |

| 508 | 6.35 | 9.53 | 12.70 | 9.53 | 15.09 | 20.62 | 12.70 | 26.19 | 32.54 | 38.10 | 44.45 | 50.01 |

| 559 | 6.35 | 9.53 | 12.70 | 9.53 | 22.23 | 12.70 | 28.58 | 34.93 | 41.28 | 47.63 | 53.98 | |

| 610 | 6.35 | 9.53 | 14.27 | 9.53 | 17.48 | 24.61 | 12.70 | 30.96 | 38.39 | 46.02 | 52.37 | 59.54 |

| 660 | 7.92 | 12.70 | 9.53 | 12.70 | ||||||||

| 711 | 7.92 | 12.70 | 15.88 | 9.53 | 12.70 | |||||||

| 762 | 7.92 | 12.70 | 15.88 | 9.53 | 12.70 | |||||||

| Lura: Ma'auni na sama da ƙayyadaddun bayanai don tunani ne kawai, za mu iya samar da samfur na musamman bisa ga buƙatar abokin ciniki. | ||||||||||||

Kula da bututun ƙarfe:

Domin inganta rayuwar sabis na mai bututun, surface jiyya yawanci da za'ayi don sauƙaƙe m hade da karfe bututu da anticorrosive coating.Common aiki hanyoyin ne: tsaftacewa, kayan aiki derusting, pickling, harbi ayukan iska mai ƙarfi derusting hudu Categories.

1 CleaningGrease, ƙura, mai mai, kwayoyin halitta da aka binne a saman bututun ƙarfe, yawanci ta yin amfani da sauran ƙarfi, emulsion don tsaftace farfajiyar. Duk da haka, tsatsa, fata oxide da waldi slag a saman bututun karfe ba za a iya cirewa ba, don haka sauran magani hanyoyin ake bukata.Tool tsatsa RemoveSteel bututu surface oxide, tsatsa, waldi slag, iya amfani da karfe waya goga don tsaftacewa da goge da surface treatment.Tool derusting za a iya raba zuwa manual da iko, manual kayan aiki derusting iya isa Sa.

Mataki na 2, derusting kayan aiki na wutar lantarki zai iya kaiwa matakin Sa3. Idan an haɗe saman bututun ƙarfe tare da fata mai ƙarfi na musamman mai ƙarfi, yana iya zama ba zai yiwu ba don cire tsatsa tare da taimakon kayan aiki, don haka muna buƙatar samun wasu hanyoyi.

3 pickling Common pickling hanyoyin sun hada da chemistry da electrolysis.Amma kawai sinadaran pickling da ake amfani da shi don kare lalata bututun.Chemical pickling zai iya cimma wani mataki na tsabta da roughness a saman saman karfe bututu, wanda ya dace da na gaba anka Lines.Yawanci a matsayin harbi (yashi) bayan sake sarrafawa.

4 harbi iska mai ƙarfi don cire tsatsa ta hanyar babban motar motsa jiki mai saurin jujjuya ruwan wukake, grit karfe, harbin karfe, sashi, ma'adanai da sauran waya mai abrasive a ƙarƙashin aikin ƙarfin centrifugal akan fesa bututun ƙarfe da fitar da taro, cire tsatsa sosai, oxides. da datti a daya hannun, a daya hannun, karfe bututu karkashin mataki na abrasive tashin hankali tasiri da gogayya karfi, don cimma da ake bukata uniform roughness.A cikin hudu jiyya hanyoyin, harbi ayukan iska mai ƙarfi da derusting ne manufa magani Hanyar for bututu derusting.Gabaɗaya, harbin iska mai ƙarfi da ɓarkewa ana amfani da su ne don jiyya da bututun ƙarfe na ciki, kuma harbin iska mai ƙarfi da derusting galibi ana amfani da su don maganin bututun ƙarfe na waje.