Alloy Seamless Pipe

OD:6-720MM

WT:0.5-120MM

Haba:3-16M

Application:Petrolyo, Chemical Engineering, Elektrisidad, Boiler

Standard:ASTM A335/A335M, ASTM A213/213M, DIN17175-79, JIS3467-88,GB5310-95

Materyal:P5,T5,P11,P12,STFA22, P22, T91, T9,WB36

Ang Alloy pipe ay isang uri ng seamless steel pipe, ang pagganap nito ay mas mataas kaysa sa pangkalahatang seamless steel pipe, dahil ang ganitong uri ng steel pipe ay naglalaman ng higit na Cr, ang mataas na temperatura na pagtutol nito, ang mababang temperatura ng pagtutol, ang pagganap ng paglaban sa kaagnasan ay mas mahusay kaysa sa iba Steel pipe , kaya ang haluang metal pipe ay malawakang ginagamit sa petrolyo, aerospace, kemikal, electric power, boiler, militar at iba pang mga industriya.

| produkto | SEAMLESS / ERW / SAW ALLOY STEEL PIPE |

| Dimensyon | 6 mm - 1080 mm |

| kapal | 1mm - 135 mm |

| Ang haba | 3 m - 12 m o ayon sa mga kinakailangan ng mga kliyente |

| Pamantayan | ASTM GB DIN |

| Grado ng bakal | A106/53/179/214/192/210 A/B/CST37.2/35.4/35.8/52/52.3/52.4/42/4510# 20# 45#P2, P12, P11, P22, P5, P29, P91T , T11,T5,T9,T22, 4140, 12CrMo, 15CrMo, 12Cr2Mo, 1Cr5Mo, 2CrMo4, 1Cr9Mo, 10CrMo910, atbp. |

| Mga tuntunin sa kalakalan | FOB/CIF/CFR |

| Kasunduan sa pagbabayad | T/T, L/C |

| Delivery port | Tianjin, China |

| Oras ng paghatid | 10 o ayon sa tunay na dami ng mga tubo |

| Paggamot sa ibabaw | Black paintingVarnish painting3PEHot galvanizedo iba pang coating ayon sa iyong mga pangangailanganBare tube |

| Dulo ng mga tubo | Beveled, plain, thread, plastic caps |

| Inspeksyon | Ultrasonic na pagsusuri, eddy inspection, hydrosttic testing atbp. |

| Package | Bundle, paluwagin o ayon sa iyong mga kinakailangan |

| Sertipiko | API 5L/5CT, ISO, PED atbp. |

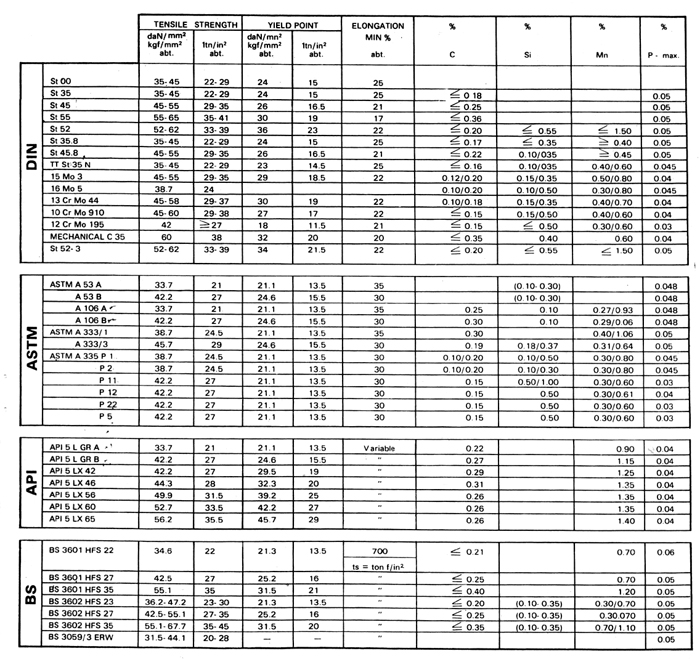

Komposisyong kemikal

| C, % | Mn, % | P, % | S, % | Si, % | Cr, % | Mo, % |

| 0.05-0.15 | 0.30-0.60 | 0.025 max | 0.025 max | 0.50-1.00 | 1.00-1.50 | 0.44-0.65 |

Mga Katangiang Mekanikal

| Lakas ng Tensile, MPa | Lakas ng Yield, MPa | Pagpahaba, % |

| 415 min | 205 min | 30 minuto |

Labas na Diameter at Pagpaparaya

| ASTM A450 | Hot rolled | Labas Diameter, mm | Pagpaparaya, mm |

| OD≤101.6 | +0.4/-0.8 | ||

| 101.6<OD≤190.5 | +0.4/-1.2 | ||

| 190.5<OD≤228.6 | +0.4/-1.6 | ||

| Cold Drawn | Labas Diameter, mm | Pagpaparaya, mm | |

| OD<25.4 | ±0.10 | ||

| 25.4≤OD≤38.1 | ±0.15 | ||

| 38.1<OD<50.8 | ±0.20 | ||

| 50.8≤OD<63.5 | ±0.25 | ||

| 63.5≤OD<76.2 | ±0.30 | ||

| 76.2≤OD≤101.6 | ±0.38 | ||

| 101.6<OD≤190.5 | +0.38/-0.64 | ||

| 190.5<OD≤228.6 | +0.38/-1.14 | ||

| ASTM A530 at ASTM A335 | NPS | Labas Diameter, pulgada | Pagpaparaya, mm |

| 1/8≤OD≤1-1/2 | ±0.40 | ||

| 1-1/2<OD≤4 | ±0.79 | ||

| 4<OD≤8 | +1.59/-0.79 | ||

| 8<OD≤12 | +2.38/-0.79 | ||

| OD>12 | ±1% |

Kapal ng pader at Pagpaparaya

| ASTM A450 | Hot rolled | Labas Diameter, mm | Pagpaparaya, % |

| OD≤101.6, WT≤2.4 | +40/-0 | ||

| OD≤101.6, 2.4<WT≤3.8 | +35/-0 | ||

| OD≤101.6, 3.8<WT≤4.6 | +33/-0 | ||

| OD≤101.6, WT>4.6 | +28/-0 | ||

| OD>101.6, 2.4<WT≤3.8 | +35/-0 | ||

| OD>101.6, 3.8<WT≤4.6 | +33/-0 | ||

| OD>101.6, WT>4.6 | +28/-0 | ||

| Cold Drawn | Labas Diameter, mm | Pagpaparaya, % | |

| OD≤38.1 | +20/-0 | ||

| OD>38.1 | +22/-0 | ||

| ASTM A530 | NPS | Labas Diameter, pulgada | Pagpaparaya, % |

| 1/8≤OD≤2-1/2 | +20.0/-12.5 | ||

| 3≤OD≤18, WT/OD≤5% | +22.5/-12.5 | ||

| 3≤OD≤18, WT/OD>5% | +15.0/-12.5 | ||

| OD≥20, WT/OD≤5% | +22.5/-12.5 | ||

| OD≥20, WT/OD>5% | +15.0/-12.5 |

ASTM A335–para sa Seamless Ferritic Alloy-Steel Pipe para sa Serbisyong Mataas ang Temperatura

ASTM A519–para sa Seamless Carbon at Alloy Steel Mechanical Tubing

ASTM A213–para sa Seamless Ferritic at Austenitic Alloy-Steel Boiler, Super heater, at Heat-Exchange Tubes

ASTM ASME (S)A-335/(S)A-335M Grado at Komposisyon ng Kemikal

| Grade | UNS | C≤ | Mn | P≤ | S≤ | Si≤ | Cr | Mo |

| P1 | K11522 | 0.10~0.20 | 0.30~0.80 | 0.025 | 0.025 | 0.10~0.50 | - | 0.44~0.65 |

| P2 | K11547 | 0.10~0.20 | 0.30~0.61 | 0.025 | 0.025 | 0.10~0.30 | 0.50~0.81 | 0.44~0.65 |

| P5 | K41545 | 0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.50 | 4.00~6.00 | 0.44~0.65 |

| P5b | K51545 | 0.15 | 0.30~0.60 | 0.025 | 0.025 | 1.00~2.00 | 4.00~6.00 | 0.44~0.65 |

| P5c | K41245 | 0.12 | 0.30~0.60 | 0.025 | 0.025 | 0.50 | 4.00~6.00 | 0.44~0.65 |

| P9 | S50400 | 0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.50~1.00 | 8.00~10.00 | 0.44~0.65 |

| P11 | K11597 | 0.05~0.15 | 0.30~0.61 | 0.025 | 0.025 | 0.50~1.00 | 1.00~1.50 | 0.44~0.65 |

| P12 | K11562 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.50 | 0.80~1.25 | 0.44~0.65 |

| P15 | K11578 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 1.15~1.65 | - | 0.44~0.65 |

| P21 | K31545 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.50 | 2.65~3.35 | 0.80~1.60 |

| P22 | K21590 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.50 | 1.90~2.60 | 0.87~1.13 |

| P91 | K91560 | 0.08~0.12 | 0.30~0.60 | 0.020 | 0.010 | 0.20~0.50 | 8.00~9.50 | 0.85~1.05 |

| P92 | K92460 | 0.07~0.13 | 0.30~0.60 | 0.020 | 0.010 | 0.50 | 8.50~9.50 | 0.30~0.60 |

Tandaan: (S)A335 P91 iba pang komposisyon ng kemikal ay: V 0.18~0.25;N 0.030~0.070;Ni≤0.40;Sinabi ni Al≤0.04 ;Nb 0.06~0.10

(S)A335 P92 iba pang kemikal na komposisyon ay: V 0.15~0.25;N 0.030~0.070;Ni≤0.40;Sinabi ni Al≤0.04 ;Nb 0.04~0.09;W 1.5~2.00 ;B 0.001~0.006

Black coating, oil/varnish, FBE,2PE,3PE, galvanized etc Detalye ng Packaging: Pag-iimpake sa mga bundle o para sa pangangailangan ng kliyente