Hindi kinakalawang na Seamless Pipe

tigas:

Ang mga hindi kinakalawang na bakal na tubo ay karaniwang ginagamit upang sukatin ang katigasan ng Brinell, Rockwell at Vickers.Brinell hardness Kabilang sa mga pamantayan ng hindi kinakalawang na asero pipe, Brinell tigas ay ang pinaka-tinatanggap na ginagamit, at ang katigasan ng materyal ay madalas na ipinahayag sa pamamagitan ng indentation diameter, na kung saan ay parehong intuitive at maginhawa.Gayunpaman, hindi ito angkop para sa mga tubo ng bakal na mas matigas o mas manipis na bakal.

Katigasan ng Rockwell:

Ang hindi kinakalawang na asero tube Rockwell hardness test ay kapareho ng Brinell hardness test.Ang pagkakaiba ay sinusukat nito ang lalim ng indentation.Ang Rockwell hardness test ay isang malawakang ginagamit na paraan kung saan ang HRC ay ginagamit na pangalawa lamang sa Brinell hardness HB sa mga pamantayan ng steel pipe.Maaaring ilapat ang katigasan ng Rockwell sa pagtukoy ng mga materyales na metal mula sa sobrang malambot hanggang sa napakatigas.Binabayaran nito ang paraan ng Brinell.Ito ay mas simple kaysa sa Brinell na pamamaraan at maaaring direktang basahin ang halaga ng katigasan mula sa dial ng hardness machine.Gayunpaman, dahil sa maliit na indentasyon nito, ang halaga ng katigasan ay hindi kasing-tumpak ng paraan ng Brinell.

Vickers tigas

Ang hindi kinakalawang na asero tube Vickers hardness test ay isa ring indentation test method para sa pagsukat ng napakanipis na metal na materyales at surface na hardness.Ito ay may mga pangunahing bentahe ng mga pamamaraan ng Brinell at Rockwell, at nagtagumpay sa kanilang mga pangunahing pagkukulang, ngunit hindi ito kasing simple ng paraan ng Rockwell.Ang pamamaraan ng Vickers ay bihirang ginagamit sa mga pamantayan ng bakal na tubo.

Pagsubok sa katigasan

Ang stainless steel tube ay may panloob na diameter na 6.0mm o higit pa at isang annealed stainless steel tube na may kapal ng pader na 13mm o mas mababa.Maaari itong maging isang W-B75 type Vickers hardness tester.Ito ay napakabilis at simpleng pagsubok at angkop para sa mabilis at hindi mapanirang inspeksyon ng mga hindi kinakalawang na asero na tubo.Ang mga hindi kinakalawang na asero na tubo na may panloob na diameter na higit sa 30 mm at ang kapal ng pader na higit sa 1.2 mm ay sinusubok gamit ang isang Rockwell hardness tester upang subukan ang HRB at HRC na tigas.Ang mga hindi kinakalawang na asero na tubo na may panloob na diameter na higit sa 30 mm at ang kapal ng pader na mas mababa sa 1.2 mm ay sinusubok gamit ang pang-ibabaw na Rockwell hardness tester upang subukan ang HRT o HRN na tigas.Para sa mga hindi kinakalawang na asero na tubo na may panloob na diameter na mas mababa sa 0 mm at mas malaki sa 4.8 mm, ang katigasan ng HR15T ay sinusuri ng isang espesyal na Rockwell hardness tester para sa mga tubo.Kapag ang panloob na diameter ng hindi kinakalawang na asero na tubo ay mas malaki kaysa sa 26 mm, ang katigasan ng panloob na dingding ng tubo ay maaari ding masuri ng isang Ro

Komposisyong kemikal

| Mga grado | C max | Mn max | P max | S max | Si max | Cr | Ni | Mo |

| 304 | 0.08 | 2.00 | 0.04 | 0.03 | 0.075 | 18.00-20.00 | 8.00-11.00 | / |

| 304L | 0.035 | 2.00 | 0.04 | 0.03 | 0.075 | 18.00-20.00 | 8.00-13.00 | / |

| 316 | 0.08 | 2.00 | 0.04 | 0.03 | 0.075 | 16.00-18.00 | 11.00-14.00 | 2.00-3.00 |

| 316L | 0.035 | 2.00 | 0.04 | 0.03 | 0.075 | 16.00-18.00 | 10.00-15.00 | 2.00-3.00 |

Mga Katangiang Mekanikal

| Mga grado | Itemper | Makunot na Psi | Magbigay ng Psi | Elong % | Katigasan ng Rockwell |

| 304 | Annealed | 85000-105000 | 35000-75000 | 20-55 | 80-95 |

| 304L | Annealed I1/8 Mahirap | 80000-105000 | 30000-75000 | 20-55 | 75-95 |

| 316 | Annealed | 85000 min | 35000 min | 50 min | 80 min |

| Annealed | 80000 min | 30000 min | 50 min | 75 min |

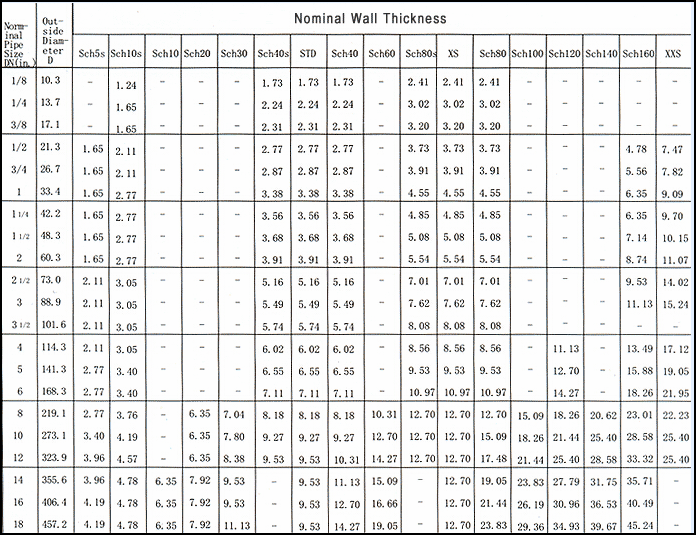

Mga Sukat ng Stainless Steel Pipe

Annealing at adobo, maliwanag na pagsusubo, pinakintab

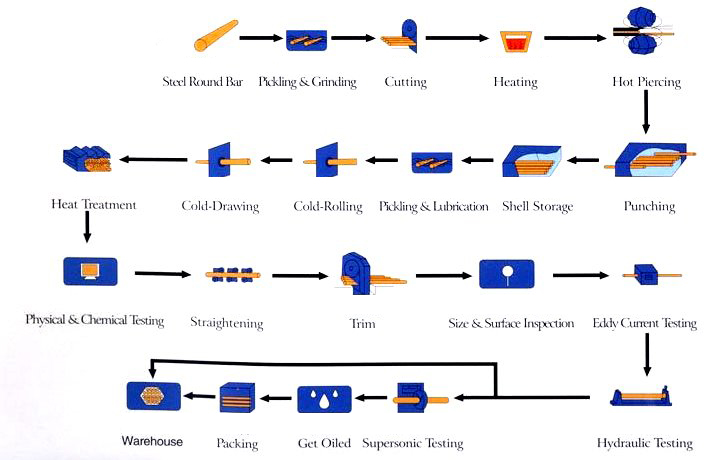

Proseso