Paslanmayan Dikişsiz Boru

Sərtlik:

Paslanmayan polad borular adətən Brinell, Rockwell və Vickers sərtliyini ölçmək üçün istifadə olunur.Brinell sərtliyi Paslanmayan polad boru standartları arasında Brinell sərtliyi ən çox istifadə olunur və materialın sərtliyi çox vaxt həm intuitiv, həm də rahat olan girinti diametri ilə ifadə edilir.Bununla belə, daha sərt və ya daha nazik poladdan olan polad borular üçün uyğun deyil.

Rockwell sərtliyi:

Paslanmayan polad boru Rockwell sərtlik testi Brinell sərtlik testi ilə eynidir.Fərq ondadır ki, girinti dərinliyini ölçür.Rockwell sərtlik testi, polad boru standartlarında HRC-nin Brinell sərtliyindən HB-dən sonra ikinci istifadə edildiyi geniş istifadə olunan bir üsuldur.Rokvell sərtliyi metal materialların həddindən artıq yumşaqdan çox sərtə qədər təyin edilməsində tətbiq oluna bilər.Brinell metodunu kompensasiya edir.Brinell metodundan daha sadədir və sərtlik maşınının siferblatından sərtlik dəyərini birbaşa oxuya bilər.Bununla belə, kiçik girintiyə görə sərtlik dəyəri Brinell metodu qədər dəqiq deyil.

Vickers sərtliyi

Paslanmayan polad boru Vickers sərtlik testi də çox nazik metal materialları və səth qatının sərtliyini ölçmək üçün girinti testi üsuludur.Brinell və Rockwell metodlarının əsas üstünlüklərinə malikdir və onların əsas çatışmazlıqlarını aradan qaldırır, lakin Rokvell metodu qədər sadə deyil.Polad boru standartlarında Vickers üsulu nadir hallarda istifadə olunur.

Sərtlik testi

Paslanmayan polad borunun daxili diametri 6,0 mm və ya daha çox və divar qalınlığı 13 mm və ya daha az olan tavlanmış paslanmayan polad boru var.Bu, W-B75 tipli Vickers sərtlik test cihazı ola bilər.Sınaq üçün çox sürətli və sadədir və paslanmayan polad boruların sürətli və qeyri-dağıdıcı yoxlanılması üçün uyğundur.Daxili diametri 30 mm-dən çox və divar qalınlığı 1,2 mm-dən çox olan paslanmayan polad borular HRB və HRC sərtliyini yoxlamaq üçün Rockwell sərtlik test cihazı ilə sınaqdan keçirilir.Daxili diametri 30 mm-dən çox və divar qalınlığı 1,2 mm-dən az olan paslanmayan polad borular HRT və ya HRN sərtliyini yoxlamaq üçün səthi Rockwell sərtlik test cihazı ilə sınaqdan keçirilir.Daxili diametri 0 mm-dən az və 4,8 mm-dən çox olan paslanmayan polad borular üçün HR15T sərtliyi borular üçün xüsusi Rockwell sərtlik test cihazı ilə yoxlanılır.Paslanmayan polad borunun daxili diametri 26 mm-dən çox olduqda, borunun daxili divarının sərtliyi də Ro tərəfindən yoxlanıla bilər.

Kimyəvi birləşmə

| Qiymətlər | C maks | Mn maks | P maks | S maks | Si maks | Cr | Ni | Mo |

| 304 | 0.08 | 2.00 | 0.04 | 0.03 | 0,075 | 18.00-20.00 | 8.00-11.00 | / |

| 304 l | 0.035 | 2.00 | 0.04 | 0.03 | 0,075 | 18.00-20.00 | 8.00-13.00 | / |

| 316 | 0.08 | 2.00 | 0.04 | 0.03 | 0,075 | 16.00-18.00 | 11.00-14.00 | 2.00-3.00 |

| 316 l | 0.035 | 2.00 | 0.04 | 0.03 | 0,075 | 16.00-18.00 | 10.00-15.00 | 2.00-3.00 |

Mexaniki xüsusiyyətləri

| Qiymətlər | Maddi | Dartma Psi | Məhsuldarlıq Psi | Uzatmaq % | Rockwell Sərtliyi |

| 304 | Tavlanmış | 85000-105000 | 35000-75000 | 20-55 | 80-95 |

| 304 l | Tavlanmış I1/8 Çətin | 80000-105000 | 30000-75000 | 20-55 | 75-95 |

| 316 | Tavlanmış | 85000 dəq | 35000 dəq | 50 dəq | 80 dəq |

| Tavlanmış | 80000 dəq | 30000 dəq | 50 dəq | 75 dəq |

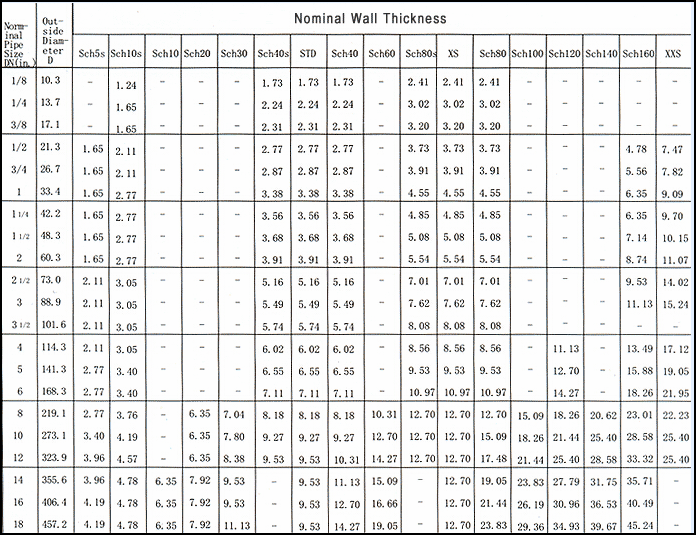

Paslanmayan Polad Boru Ölçüləri

Tavlanmış və turşu, parlaq tavlama, cilalanmış

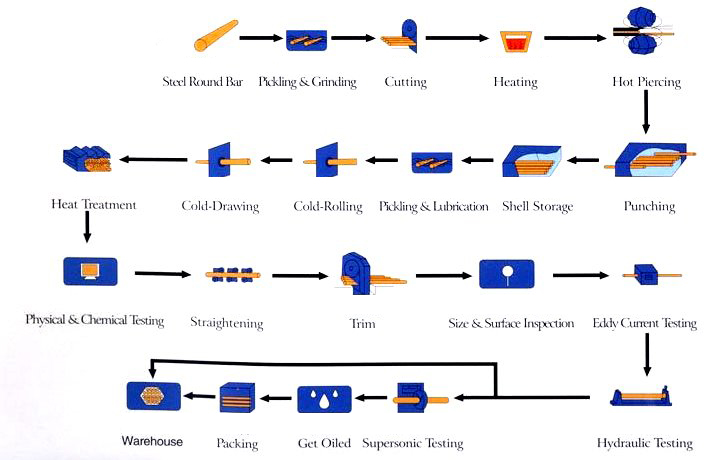

Proses