Paslanmaz Dikişsiz Boru

Sertlik:

Brinell, Rockwell ve Vickers sertliğini ölçmek için yaygın olarak paslanmaz çelik borular kullanılır.Brinell sertliği Paslanmaz çelik boru standartları arasında Brinell sertliği en yaygın kullanılanıdır ve malzemenin sertliği genellikle hem sezgisel hem de kullanışlı olan girinti çapıyla ifade edilir.Ancak daha sert veya daha ince çelikten yapılmış çelik borular için uygun değildir.

Rockwell sertliği:

Paslanmaz çelik boru Rockwell sertlik testi Brinell sertlik testiyle aynıdır.Aradaki fark girintinin derinliğini ölçmesidir.Rockwell sertlik testi, HRC'nin çelik boru standartlarında Brinell sertliği HB'den sonra ikinci olarak kullanıldığı yaygın olarak kullanılan bir yöntemdir.Rockwell sertliği, aşırı yumuşaktan çok serte kadar metal malzemelerin belirlenmesinde uygulanabilir.Brinell yöntemini telafi eder.Brinell yönteminden daha basittir ve sertlik değerini doğrudan sertlik makinesinin kadranından okuyabilir.Ancak girintinin küçük olması nedeniyle sertlik değeri Brinell yöntemi kadar doğru değildir.

Vickers sertliği

Paslanmaz çelik boru Vickers sertlik testi aynı zamanda çok ince metal malzemeleri ve yüzey katmanı sertliğini ölçmek için kullanılan bir girinti testi yöntemidir.Brinell ve Rockwell yöntemlerinin temel avantajlarına sahiptir ve temel eksikliklerini giderir ancak Rockwell yöntemi kadar basit değildir.Vickers yöntemi çelik boru standartlarında nadiren kullanılır.

Sertlik testi

Paslanmaz çelik borunun iç çapı 6,0 mm veya daha fazladır ve et kalınlığı 13 mm veya daha az olan tavlanmış paslanmaz çelik borudur.W-B75 tipi Vickers sertlik test cihazı olabilir.Test edilmesi çok hızlı ve basittir ve paslanmaz çelik boruların hızlı ve tahribatsız muayenesi için uygundur.İç çapı 30 mm'den fazla ve et kalınlığı 1,2 mm'den fazla olan paslanmaz çelik borular, HRB ve HRC sertliğini test etmek için Rockwell sertlik test cihazıyla test edilir.İç çapı 30 mm'den fazla ve et kalınlığı 1,2 mm'den az olan paslanmaz çelik borular, HRT veya HRN sertliğini test etmek için bir yüzey Rockwell sertlik test cihazıyla test edilir.İç çapı 0 mm'den küçük ve 4,8 mm'den büyük olan paslanmaz çelik borular için HR15T'nin sertliği, borular için özel bir Rockwell sertlik test cihazı ile test edilir.Paslanmaz çelik borunun iç çapı 26 mm'den büyük olduğunda borunun iç duvarının sertliği de Ro ile test edilebilir.

Kimyasal bileşim

| Notlar | Cmaks | Mn maks | Pmaks | Smaks | Si maksimum | Cr | Ni | Mo |

| 304 | 0,08 | 2.00 | 0,04 | 0,03 | 0,075 | 18.00-20.00 | 8.00-11.00 | / |

| 304L | 0,035 | 2.00 | 0,04 | 0,03 | 0,075 | 18.00-20.00 | 8.00-13.00 | / |

| 316 | 0,08 | 2.00 | 0,04 | 0,03 | 0,075 | 16.00-18.00 | 11.00-14.00 | 2.00-3.00 |

| 316L | 0,035 | 2.00 | 0,04 | 0,03 | 0,075 | 16.00-18.00 | 10.00-15.00 | 2.00-3.00 |

Mekanik özellikler

| Notlar | Öğeci | Çekme Psi'si | Verim Psi | Uzama %'si | Rockwell Sertliği |

| 304 | Tavlanmış | 85000-105000 | 35000-75000 | 20-55 | 80-95 |

| 304L | Tavlanmış I1/8 Zor | 80000-105000 | 30000-75000 | 20-55 | 75-95 |

| 316 | Tavlanmış | 85000 dk | 35000 dk | 50 dakika | 80 dakika |

| Tavlanmış | 80000 dk | 30000 dk | 50 dakika | 75 dakika |

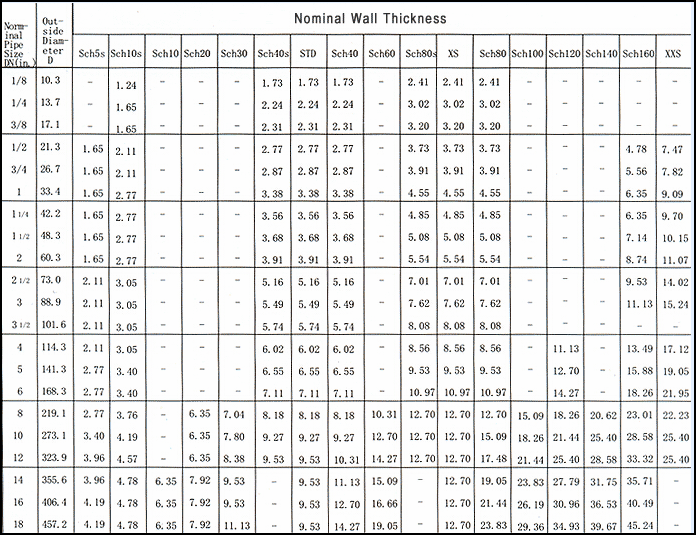

Paslanmaz Çelik Boru Boyutları

Tavlanmış ve salamura edilmiş, parlak tavlama, cilalı

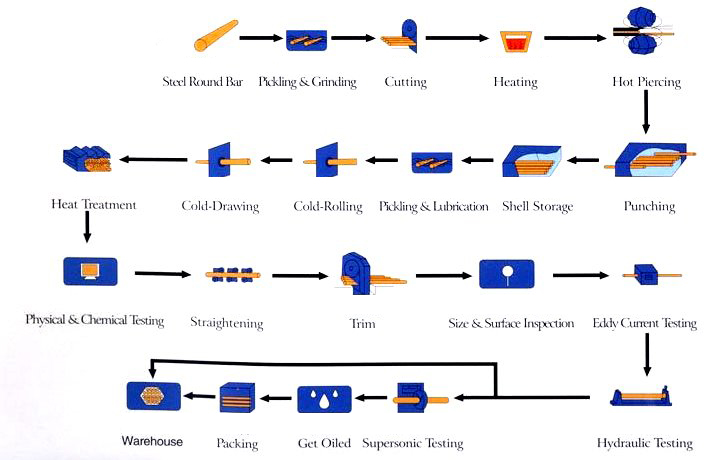

İşlem