Roestvrij naadloze buis

Hardheid:

Roestvrijstalen buizen worden vaak gebruikt om de hardheid van Brinell, Rockwell en Vickers te meten.Brinell-hardheid Van de roestvrijstalen buisstandaarden wordt de Brinell-hardheid het meest gebruikt, en de hardheid van het materiaal wordt vaak uitgedrukt door de inkepingsdiameter, die zowel intuïtief als handig is.Het is echter niet geschikt voor stalen buizen van harder of dunner staal.

Rockwell-hardheid:

De Rockwell-hardheidstest van roestvrijstalen buizen is dezelfde als de Brinell-hardheidstest.Het verschil is dat het de diepte van de inkeping meet.De Rockwell-hardheidstest is een veelgebruikte methode waarbij HRC in stalen buisnormen de tweede plaats krijgt na Brinell-hardheid HB.Rockwell-hardheid kan worden toegepast bij het bepalen van metalen materialen van extreem zacht tot zeer hard.Het compenseert de Brinell-methode.Het is eenvoudiger dan de Brinell-methode en kan de hardheidswaarde direct aflezen van de wijzerplaat van de hardheidsmachine.Vanwege de kleine inkeping is de hardheidswaarde echter niet zo nauwkeurig als de Brinell-methode.

Vickers-hardheid

De Vickers-hardheidstest met roestvrijstalen buizen is ook een inkepingstestmethode voor het meten van zeer dunne metalen materialen en de hardheid van de oppervlaktelaag.Het heeft de belangrijkste voordelen van de Brinell- en Rockwell-methoden en overwint hun fundamentele tekortkomingen, maar het is niet zo eenvoudig als de Rockwell-methode.De Vickers-methode wordt zelden gebruikt in normen voor stalen buizen.

Hardheidstest

De roestvrijstalen buis heeft een binnendiameter van 6,0 mm of meer en een gegloeide roestvrijstalen buis met een wanddikte van 13 mm of minder.Het kan een Vickers-hardheidsmeter van het type W-B75 zijn.Het is zeer snel en eenvoudig te testen en geschikt voor snelle en niet-destructieve inspectie van roestvrijstalen buizen.Roestvrijstalen buizen met een binnendiameter van meer dan 30 mm en een wanddikte groter dan 1,2 mm worden getest met een Rockwell-hardheidsmeter om de HRB- en HRC-hardheid te testen.Roestvrijstalen buizen met een binnendiameter van meer dan 30 mm en een wanddikte van minder dan 1,2 mm worden getest met een Rockwell-hardheidsmeter voor het oppervlak om de HRT- of HRN-hardheid te testen.Voor roestvrijstalen buizen met een binnendiameter kleiner dan 0 mm en groter dan 4,8 mm wordt de hardheid van HR15T getest door een speciale Rockwell hardheidsmeter voor buizen.Wanneer de binnendiameter van de roestvrijstalen buis groter is dan 26 mm, kan de hardheid van de binnenwand van de buis ook worden getest door een Ro

Chemische samenstelling

| Cijfers | Cmax | Mn max | P-max | S maximaal | Ja max | Cr | Ni | Mo |

| 304 | 0,08 | 2.00 | 0,04 | 0,03 | 0,075 | 18.00-20.00 uur | 8.00-11.00 uur | / |

| 304L | 0,035 | 2.00 | 0,04 | 0,03 | 0,075 | 18.00-20.00 uur | 8.00-13.00 uur | / |

| 316 | 0,08 | 2.00 | 0,04 | 0,03 | 0,075 | 16.00-18.00 uur | 11.00-14.00 uur | 2.00-3.00 uur |

| 316L | 0,035 | 2.00 | 0,04 | 0,03 | 0,075 | 16.00-18.00 uur | 10.00-15.00 uur | 2.00-3.00 uur |

Mechanische eigenschappen

| Cijfers | Artikelpersoon | Treksterkte Psi | Opbrengst Psi | Verleng % | Rockwell-hardheid |

| 304 | Gegloeid | 85000-105000 | 35000-75000 | 20-55 | 80-95 |

| 304L | Gegloeid I1/8 Moeilijk | 80000-105000 | 30000-75000 | 20-55 | 75-95 |

| 316 | Gegloeid | 85000 min | 35000 min | 50 min | 80 minuten |

| Gegloeid | 80000 min | 30000 min | 50 min | 75 min |

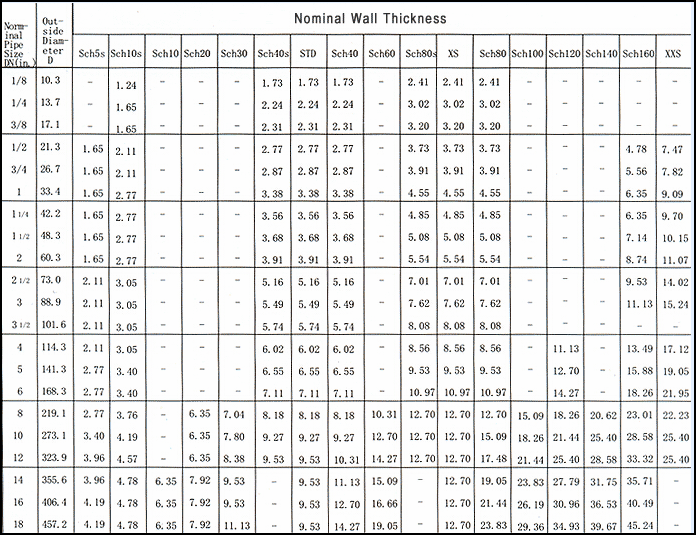

Maten van roestvrijstalen buizen

Gegloeid en gebeitst, helder gloeien, gepolijst

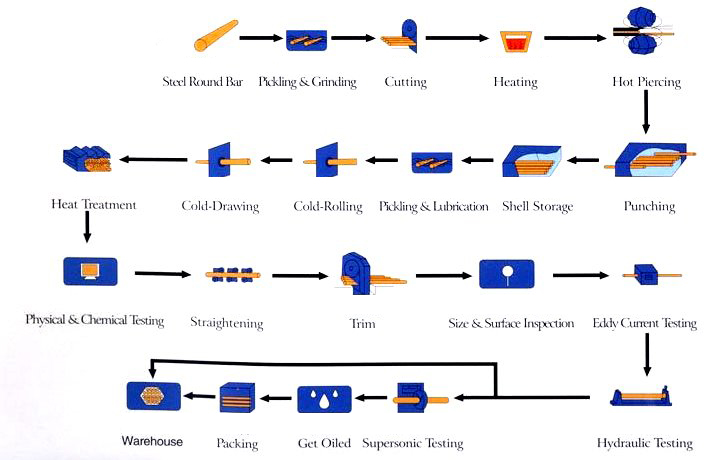

Proces