Paip Lancar Tahan Karat

Kekerasan:

Tiub keluli tahan karat biasanya digunakan untuk mengukur kekerasan Brinell, Rockwell dan Vickers.Kekerasan Brinell Di antara piawaian paip keluli tahan karat, kekerasan Brinell adalah yang paling banyak digunakan, dan kekerasan bahan sering dinyatakan oleh diameter lekukan, yang intuitif dan mudah.Walau bagaimanapun, ia tidak sesuai untuk paip keluli daripada keluli yang lebih keras atau nipis.

Kekerasan Rockwell:

Ujian kekerasan Rockwell tiub keluli tahan karat adalah sama dengan ujian kekerasan Brinell.Perbezaannya ialah ia mengukur kedalaman lekukan.Ujian kekerasan Rockwell ialah kaedah yang digunakan secara meluas di mana HRC digunakan kedua selepas kekerasan Brinell HB dalam piawaian paip keluli.Kekerasan Rockwell boleh digunakan untuk penentuan bahan logam daripada sangat lembut kepada sangat keras.Ia mengimbangi kaedah Brinell.Ia lebih mudah daripada kaedah Brinell dan boleh membaca terus nilai kekerasan daripada dail mesin kekerasan.Walau bagaimanapun, disebabkan lekukan yang kecil, nilai kekerasan tidak setepat kaedah Brinell.

Kekerasan Vickers

Ujian kekerasan Vickers tiub keluli tahan karat juga merupakan kaedah ujian lekukan untuk mengukur bahan logam yang sangat nipis dan kekerasan lapisan permukaan.Ia mempunyai kelebihan utama kaedah Brinell dan Rockwell, dan mengatasi kelemahan asas mereka, tetapi ia tidak semudah kaedah Rockwell.Kaedah Vickers jarang digunakan dalam piawaian paip keluli.

Ujian kekerasan

Tiub keluli tahan karat mempunyai diameter dalam 6.0mm atau lebih dan tiub keluli tahan karat anil dengan ketebalan dinding 13mm atau kurang.Ia boleh menjadi penguji kekerasan Vickers jenis W-B75.Ia sangat pantas dan mudah untuk diuji dan sesuai untuk pemeriksaan pantas dan tidak merosakkan paip keluli tahan karat.Tiub keluli tahan karat dengan diameter dalam lebih daripada 30 mm dan ketebalan dinding lebih daripada 1.2 mm diuji dengan penguji kekerasan Rockwell untuk menguji kekerasan HRB dan HRC.Tiub keluli tahan karat dengan diameter dalam lebih daripada 30 mm dan ketebalan dinding kurang daripada 1.2 mm diuji dengan penguji kekerasan Rockwell permukaan untuk menguji kekerasan HRT atau HRN.Untuk paip keluli tahan karat dengan diameter dalam kurang daripada 0 mm dan lebih besar daripada 4.8 mm, kekerasan HR15T diuji oleh penguji kekerasan Rockwell khas untuk paip.Apabila diameter dalam tiub keluli tahan karat lebih besar daripada 26 mm, kekerasan dinding dalam tiub juga boleh diuji oleh Ro

Komposisi kimia

| Gred | C maks | Mn maks | P maks | S maks | Si max | Cr | Ni | Mo |

| 304 | 0.08 | 2.00 | 0.04 | 0.03 | 0.075 | 18.00-20.00 | 8.00-11.00 | / |

| 304L | 0.035 | 2.00 | 0.04 | 0.03 | 0.075 | 18.00-20.00 | 8.00-13.00 | / |

| 316 | 0.08 | 2.00 | 0.04 | 0.03 | 0.075 | 16.00-18.00 | 11.00-14.00 | 2.00-3.00 |

| 316L | 0.035 | 2.00 | 0.04 | 0.03 | 0.075 | 16.00-18.00 | 10.00-15.00 | 2.00-3.00 |

Sifat Mekanikal

| Gred | Itemper | Psi tegangan | Hasil Psi | Panjang % | Kekerasan Rockwell |

| 304 | disepuh | 85000-105000 | 35000-75000 | 20-55 | 80-95 |

| 304L | disepuh I1/8 Keras | 80000-105000 | 30000-75000 | 20-55 | 75-95 |

| 316 | disepuh | 85000 min | 35000 min | 50 min | 80 min |

| disepuh | 80000 min | 30000 min | 50 min | 75 min |

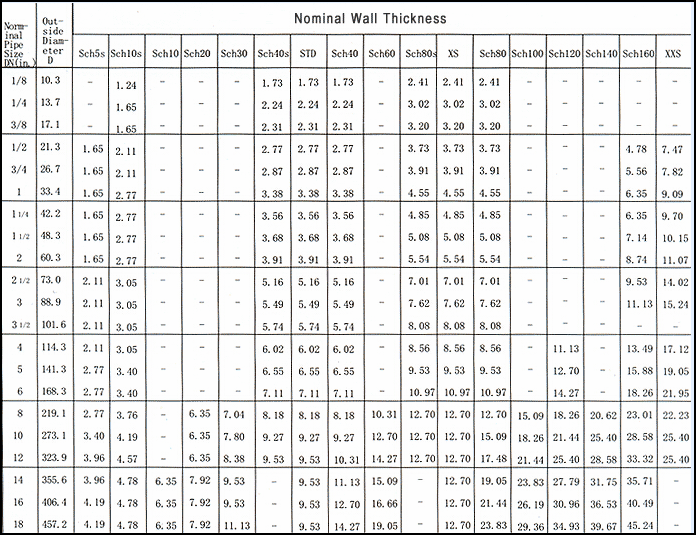

Saiz Paip Keluli Tahan Karat

Anil & jeruk, penyepuhlindapan terang, digilap

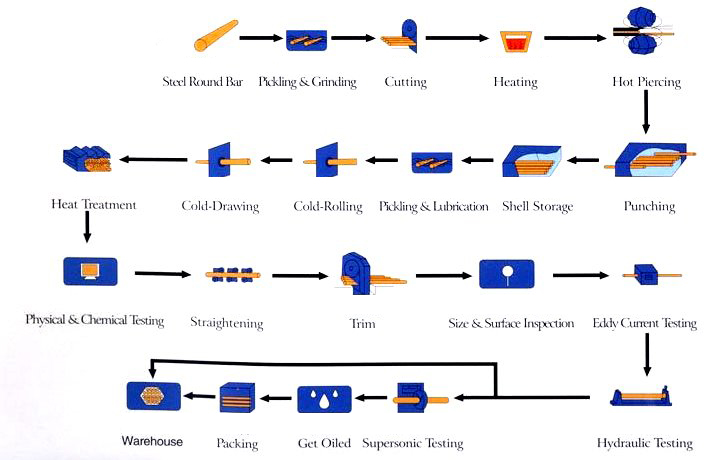

Proses