Paip Keluli ERW

(1) paip dikimpal dari kimpalan plat keluli ke dalam paip bulat, dibahagikan kepada paip dikimpal rintangan frekuensi tinggi (paip dikimpal ERW), paip kimpalan arka jahitan lurus (LSAW), paip dikimpal lingkaran. Kejuruteraan elektrik dengan "SC", boleh digunakan sebagai paip gas air juga boleh digunakan sebagai paip threading, agak tebal.

(2) Paip saluran paip, juga dikenali sebagai paip dawai, adalah agak nipis, dilambangkan dengan "T", dan hanya boleh digunakan untuk penyulingan. Paip keluli ERW Paip keluli ERW

(3) Tiub ERW adalah "tiub keluli kimpalan rintangan frekuensi tinggi", dan proses kimpalan biasa adalah berbeza, garis kimpalan adalah dari bahan asas badan tali pinggang keluli cair, kekuatan mekanikal lebih baik daripada kimpalan umum. ERW berdiri untuk kimpalan rintangan, kimpalan rintangan mempunyai ciri-ciri kecekapan pengeluaran yang tinggi, kos rendah, penjimatan bahan dan automasi mudah, jadi ia digunakan secara meluas dalam penerbangan, aeroangkasa, tenaga, elektronik, automotif, industri ringan dan sektor perindustrian lain, adalah salah satu daripada proses kimpalan yang penting.

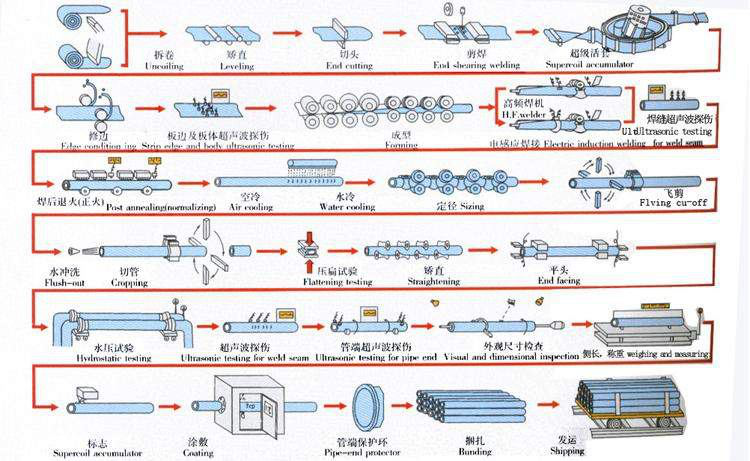

Proses Pengeluaran untuk paip keluli ERW:

Membuka gegelung --- 2. Meratakan --- 3. Pemotongan hujung --- 4. Kimpalan ricih akhir --- 5. Penumpuk supergegelung --- 6. Pemotongan tepi --- 7. Pengesanan ultrasonik --- 8. Pembentukan - -- 9. Kimpalan aruhan elektrik --- 10. Pengesanan ultrasonik untuk jahitan kimpalan --- 11. Rawatan haba frekuensi sederhana --- 12. Penyejukan udara --- 13. Penyejukan air --- 14. Saiz --- 15 Pemotongan terbang --- 16. Flush-out --- 17. Pemotongan --- 18. Ujian merata --- 19. Meluruskan --- 20. Menghadap hujung dan menyerong --- 21. Ujian hidrodinamik --- 22 Pengesanan ultrasonik untuk jahitan kimpalan --- 23. Pengesanan ultrasonik untuk hujung paip --- 24. Pemeriksaan visual dan dimensi --- 25. Pemberat dan pengukuran --- 26. Penandaan --- 27. Salutan --- 28. Perlindungan hujung paip --- 29. Membengkok --- 30. Penghantaran

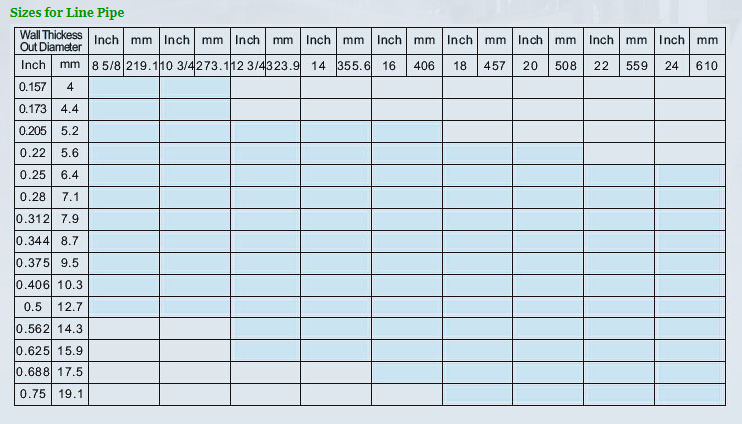

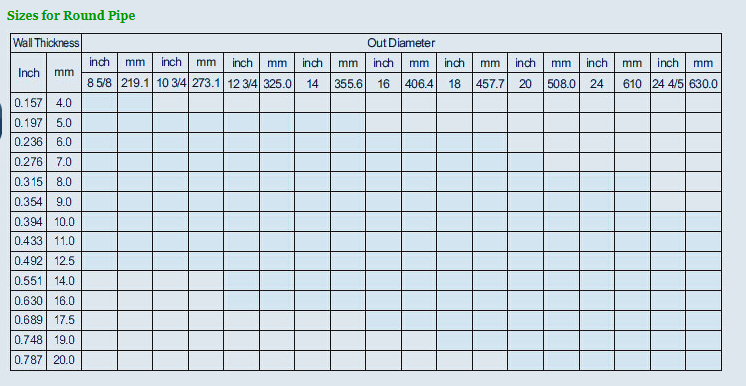

Dimensi, Spesifikasi, Saiz Paip Keluli ERW

| OD | WT | |||||||||||||||||||||||||

| Inci | mm | Inci | mm | Inci | mm | Inci | mm | Inci | mm | Inci | mm | Inci | mm | Inci | mm | Inci | mm | Inci | mm | Inci | mm | Inci | mm | Inci | mm | |

| 0.157 | 4 | 0.173 | 4.4 | 0.205 | 5.2 | 0.22 | 5.6 | 0.25 | 6.4 | 0.28 | 7.1 | 0.312 | 7.9 | 0.344 | 8.7 | 0.375 | 9.5 | 0.406 | 10.3 | 0.5 | 12.7 | 0.562 | 14.3 | |||

| 8 5/8 | 219.1 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 10 3/4 | 273.1 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 12 3/4 | 323.9 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 14 | 355.6 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 16 | 406 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 18 | 457 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 20 | 508 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 10022 | 559 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 241 | 610 |

|

|

|

|

|

|

|

|

|

|

| ||||||||||||||

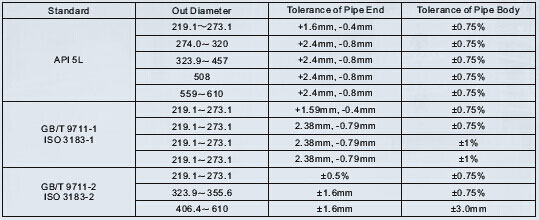

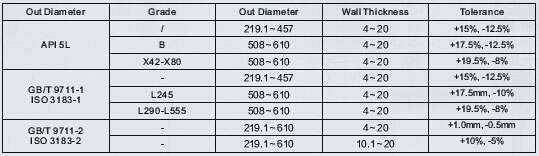

Toleransi Diameter Luar - Paip Keluli ERW

Toleransi Ketebalan Dinding – Paip Keluli ERW

Berminyak ringan, Tergalvani Hot dip, Tergalvani Elektro, Hitam, Bare, Salutan varnis/Minyak anti karat, Salutan Pelindung