Tubo de aço ERW

(1) tubo soldado de soldagem de placa de aço em tubo redondo, dividido em tubo soldado de resistência de alta frequência (tubo soldado ERW), tubo de soldagem a arco de costura reta (LSAW), tubo soldado em espiral.Engenharia elétrica com "SC", pode ser usada como tubo de gás de água também pode ser usado como tubo de rosqueamento, relativamente grosso.

(2) O tubo de tubulação, também conhecido como tubo de arame, é relativamente fino, indicado por "T", e só pode ser usado para rosqueamento.Tubo de aço ERWTubo de aço ERW

(3) O tubo ERW é "tubo de aço para soldagem por resistência de alta frequência", e o processo de soldagem comum é diferente, a linha de solda é do material base do corpo da correia de aço derretido, a resistência mecânica é melhor do que a soldagem geral. para soldagem por resistência, a soldagem por resistência tem características de alta eficiência de produção, baixo custo, economia de material e fácil automação, por isso é amplamente utilizada na aviação, aeroespacial, energia, eletrônica, automotiva, indústria leve e outros setores industriais, é um dos importantes processos de soldagem.

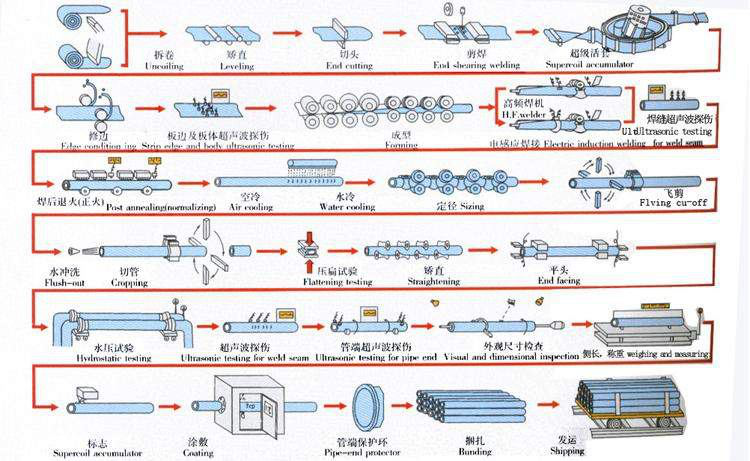

Processo de produção para tubo de aço ERW:

Desenrolamento --- 2. Nivelamento --- 3. Corte final --- 4. Soldagem de cisalhamento final --- 5. Acumulador de superbobina --- 6. Corte de borda --- 7. Detecção ultrassônica --- 8. Formação - -- 9. Soldagem por indução elétrica --- 10. Detecção ultrassônica para costura de solda --- 11. Tratamento térmico de média frequência --- 12. Resfriamento de ar --- 13. Resfriamento de água --- 14. Dimensionamento --- 15 Corte voador --- 16. Revestimento --- 17. Corte --- 18. Teste de achatamento --- 19. Endireitamento --- 20. Faceamento final e chanfro --- 21. Teste hidrodinâmico --- 22 Detecção ultrassônica para costura de solda --- 23. Detecção ultrassônica para extremidade do tubo --- 24. Inspeção visual e de dimensões --- 25.Pesagem e medição --- 26. Marcação --- 27. Revestimento --- 28. Proteção da extremidade do tubo --- 29. Dobra --- 30. Envio

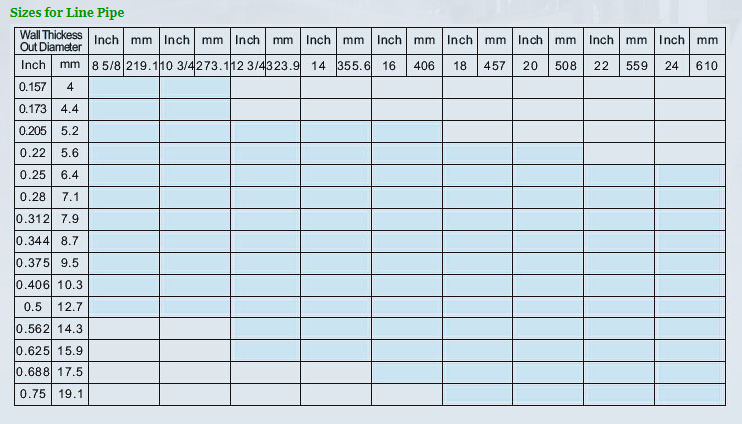

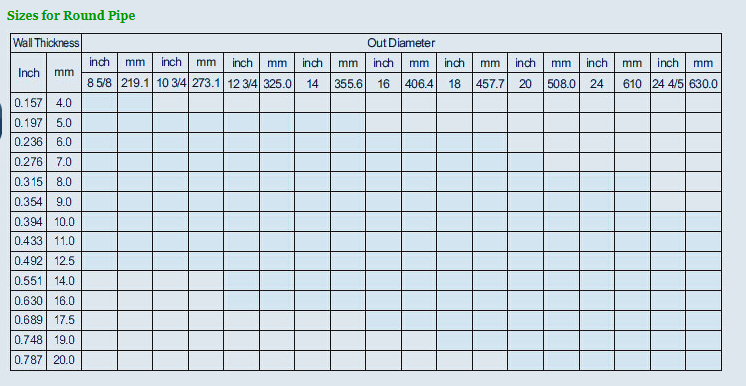

Dimensões, especificações e tamanhos de tubo de aço ERW

| OD | WT | |||||||||||||||||||||||||

| Polegada | mm | Polegada | mm | Polegada | mm | Polegada | mm | Polegada | mm | Polegada | mm | Polegada | mm | Polegada | mm | Polegada | mm | Polegada | mm | Polegada | mm | Polegada | mm | Polegada | mm | |

| 0,157 | 4 | 0,173 | 4.4 | 0,205 | 5.2 | 0,22 | 5.6 | 0,25 | 6.4 | 0,28 | 7.1 | 0,312 | 7,9 | 0,344 | 8.7 | 0,375 | 9,5 | 0,406 | 10.3 | 0,5 | 12,7 | 0,562 | 14.3 | |||

| 8 5/8 | 219.1 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 10 3/4 | 273,1 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 12 3/4 | 323,9 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 14 | 355,6 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 16 | 406 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 18 | 457 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 20 | 508 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 10022 | 559 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 241 | 610 |

|

|

|

|

|

|

|

|

|

|

| ||||||||||||||

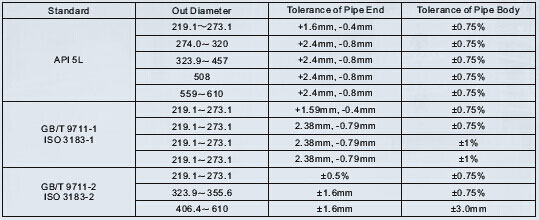

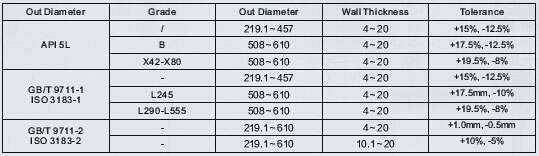

Tolerâncias de Diâmetro Externo – Tubo de Aço ERW

Tolerâncias de Espessura de Parede – Tubo de Aço ERW

Levemente oleado, galvanizado por imersão a quente, eletrogalvanizado, preto, nu, revestimento de verniz/óleo anti-ferrugem, revestimentos protetores