Tubo sem costura de aço carbono

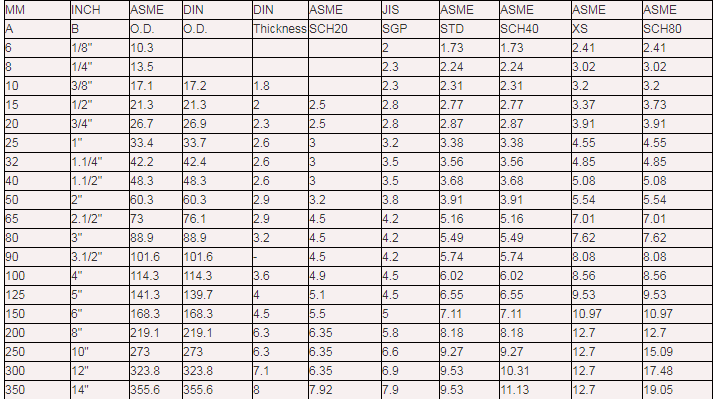

O tubo de aço sem costura é feito de aço redondo sólido'boleto'que é aquecido e empurrado ou puxado sobre uma forma até que o aço seja moldado em um tubo oco.O tubo sem costura é então acabado de acordo com as especificações dimensionais e de espessura da parede em tamanhos de 1/8 a 32 polegadas de diâmetro externo.Tubos / tubos sem costura de aço carbono O aço carbono é uma liga que consiste em ferro e carbono.A porcentagem de carbono no aço afeta a dureza, resistência, elasticidade e ductilidade do aço carbono.Tubo de aço carbono sem costura ou lingote de aço sólido é feito do tubo capilar através do orifício e, em seguida, através do laminado a quente, laminado a frio ou chamado a frio.O tubo de aço carbono sem costura na indústria siderúrgica da China ocupa uma posição importante.O material de tubo de aço carbono sem costura é um tubo redondo, embriões de máquina de corte de tubo para cortar cerca de 1 m de comprimento em branco e enviado por aquecimento de forno de correia transportadora.O tarugo é alimentado no forno de aquecimento, a temperatura é de cerca de 1200 graus Celsius.O combustível é hidrogênio ou acetileno.O controle da temperatura do forno é a questão principal.Um tubo redondo saiu para perfurar a máquina através da pressão do ar.Geralmente o punção mais comum é a máquina de perfuração de rolo cônico, o punção de alta eficiência de produção, qualidade do produto, expansão de furo de grande diâmetro, pode usar uma variedade de aço.A perfuração, tubo redondo, foi realizada em laminação cruzada, laminação ou extrusão de três rolos.Espremeu o tubo após o dimensionamento.Dimensionamento por meio de cone rotativo de alta velocidade, faça furos no tarugo para formar um tubo.Diâmetro do tubo pelo moinho de dimensionamento para determinar o comprimento do diâmetro da broca.Após o tubo passar pelo dimensionamento para a torre de resfriamento, o resfriamento por spray de água, o aço após o resfriamento, deve ser endireitado.Após a correia de aço ser enviada por endireitamento de máquina de teste de metal (ou teste de pressão) para testes internos.Se o tubo apresentar rachaduras internas, bolhas e outros problemas serão detectados.Após o tubo, mas também através de seleção manual de controle de qualidade rigoroso.Qualidade do aço, uso de números de tinta spray, especificações, número do lote de produção.Por um guindaste no armazém.

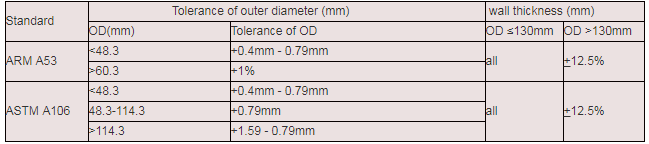

A espessura da parede do tubo sem costura

Tolerância do diâmetro externo e espessura da parede

| Padrão | Descrição |

| ASTM A179/A179M | Trocador de calor e tubos condensadores de aço de baixa liga trefilados a frio sem costura. |

| API 5L | Tubo de linha. |

| ASTM A53M | Tubo de aço soldado e sem costura revestido de preto e zinco. |

| ASTM A106M | Tubo de aço carbono sem costura para serviço em altas temperaturas. |

| ASTM A105M | Forjados em aço carbono para aplicações em tubulações. |

| ASTM A234M | Conexões de tubulação em aço carbono forjado e aço-liga para serviços em temperaturas moderadas e altas. |

| ASTM 3799 | Acessórios para tubos de aço, soldabilidade parafusada e de encaixe para a indústria petrolífera. |

| COMO 1163 | Seções ocas de aço estrutural |

| COMO 1074 | Tubos de aço e tubulares para serviços comuns |

| BS13872 | Tubos e tubulares de aço parafusados e encaixados |

| Padrão | Tipo de tubo | Aula | Nota |

| API SPEC 5L ISO 3183 | SMLS | PLS1 | L245B, L290 X42, L320 X46, L360 X52, L390 X56, L415 X60, L450 X65, L485 X70 |

| PLS2 | L245N BN, L290N X42N, L320N X46N, L360N X52N, L390N X56N, L415N X60N, L360Q X52Q, L390Q X56Q, L415Q X60Q, L485Q X70Q

| ||

| PLS2 Ambiente Azedo | L245NS BNS, L290NS X42NS, L320NS X46NS L360NS X52NS, L390NS X56NS, L415NS X60NS, L360QS X52QS, L390QS X56QS, L415QS X60QS L485QS X70QS

| ||

| SOLDAR | PLS1 | L245B, L290 X42, L320 X46, L360 X52 L390 X56, L415 X60, L450 X65, L485 X70 | |

| PLS2 | L245MBM, L290M X42M, L320M X46M, L360M X52M, L390M X56M, L415M X60M, L450M X65M, L485M X70M, L555M X80M, | ||

| Padrão | Nota |

| ASTM A 53M | UMA, B |

| ASTM A106M | A, B, C |

| JIS G 3454 | STPG 370, STPG 410 |

| JIS G 3455 | STPG370, STPG410, STPG480 |

| JIS G 3456 | STPG370, STPG410, STPG480 |

Nota: Composição química (%):

| Padrão | Nota | C | Si | Mn | P | S | Ni | Cr | Cu | Mo | V |

| ASTMA 53 milhões | A | ≤0,25 | - | ≤0,95 | ≤0,05 | ≤0,045 | ≤0,40 | ≤0,40 | ≤0,40 | ≤0,15 | ≤0,08 |

| B | ≤0,30 | - | ≤1,20 | ≤0,05 | ≤0,045 | ≤0,40 | ≤0,40 | ≤0,40 | ≤0,15 | ≤0,08 | |

| ASTM A106M | A | ≤0,25 | ≥0,10 | 0,27-0,93 | ≤0,035 | ≤0,035 | ≤0,40 | ≤0,40 | ≤0,40 | ≤0,15 | ≤0,08 |

| B | ≤0,30 | ≥0,10 | 0,29-1,06 | ≤0,035 | ≤0,035 | ≤0,40 | ≤0,40 | ≤0,40 | ≤0,15 | ≤0,08 | |

| C | ≤0,35 | ≥0,10 | 0,29-1,06 | ≤0,035 | ≤0,035 | ≤0,40 | ≤0,40 | ≤0,40 | ≤0,15 | ≤0,08 | |

| JIS G 3454 | STPG 370 | ≤0,25 | ≤0,35 | 0,30-0,90 | ≤0,040 | ≤0,040 | - | - | - | - | - |

| STPG 410 | ≤0,30 | ≤0,35 | 0h30-1h00 | ≤0,040 | ≤0,040 | - | - | - | - | - | |

| JIS G 3455 | STS 370 | ≤0,25 | 0,10-0,35 | 0h30-1h10 | ≤0,035 | ≤0,035 | - | - | - | - | - |

| STS 410 | ≤0,30 | 0,10-0,35 | 0,30-1,40 | ≤0,035 | ≤0,035 | - | - | - | - | - | |

| STS 480 | ≤0,33 | 0,10-0,35 | 0,30-1,50 | ≤0,035 | ≤0,035 | - | - | - | - | - | |

| JIS G 3456 | STPT 370 | ≤0,25 | 0,10-0,35 | 0,30-0,90 | ≤0,035 | ≤0,035 | - | - | - | - | - |

| STPT 410 | ≤0,30 | 0,10-0,35 | 0h30-1h00 | ≤0,035 | ≤0,035 | - | - | - | - | - | |

| STPT 480 | ≤0,33 | 0,10-0,35 | 0h30-1h00 | ≤0,035 | ≤0,035 | - | - | - | - | - |

Tratamento de superfície de tubo de aço: A fim de melhorar a vida útil do oleoduto, o tratamento de superfície geralmente é realizado para facilitar a combinação firme de tubo de aço e revestimento anticorrosivo. Os métodos de processamento comuns são: limpeza, remoção de ferrugem de ferramentas, decapagem, remoção de ferrugem por jateamento quatro categorias.1 limpezaGraxa, poeira, lubrificante, matéria orgânica aderida na superfície do tubo de aço, geralmente usando solvente, emulsão para limpar a superfície. No entanto, a ferrugem, a pele de óxido e a escória de soldagem na superfície do tubo de aço não podem ser removidas, então outros métodos de tratamento são necessários. Remoção de ferrugem da ferramenta Óxido de superfície do tubo de aço, ferrugem, escória de soldagem, pode usar escova de arame de aço para limpar e polir o tratamento de superfície. a remoção de ferrugem da ferramenta pode atingir o nível Sa3. Se a superfície do tubo de aço estiver fixada com uma camada de óxido particularmente forte, pode ser impossível remover a ferrugem com a ajuda de ferramentas, por isso precisamos encontrar outras maneiras.3 decapagem Os métodos comuns de decapagem incluem química e eletrólise. Mas apenas a decapagem química é usada para proteção contra corrosão de tubulações. tiro (areia) após o reprocessamento.4 jateamento para remoção de ferrugemPor motor de alta potência aciona as lâminas rotativas de alta velocidade, granalha de aço, granalha de aço, segmento, minerais e outros fios abrasivos sob a ação da força centrífuga na pulverização da superfície do tubo de aço e ejeção de massa, remova completamente a ferrugem, óxidos e sujeira por um lado, por outro lado, tubo de aço sob a ação de impacto violento abrasivo e força de fricção, para alcançar a rugosidade uniforme necessária. Entre os quatro métodos de tratamento, jateamento e remoção de ferrugem são um método de tratamento ideal para remoção de ferrugem de tubos.Geralmente, o jateamento e a remoção de ferrugem são usados principalmente para o tratamento da superfície interna de tubos de aço, e o jateamento e a remoção de ferrugem são usados principalmente para o tratamento da superfície externa de tubos de aço.

Tinta spray

Tinta spray

Embalagem à prova d'água