Ipayipi le-Carbon Steel elingenamthungo

Ipayipi Lensimbi Elingenamthungo lenziwe ngensimbi eqinile eyindilinga'billet'eshiselwa futhi iphushwe noma idonswe phezu kwefomu kuze kube yilapho insimbi ibunjwa ibe yishubhu elingenalutho.Ipayipi elingenamthungo libe seliqedwa libe ukucaciswa kobukhulu nokuqina kodonga ngosayizi ukusuka ku-1/8 intshi ukuya ku-32 intshi OD.I-Carbon Steel Seamless Pipes / Tubes Insimbi yensimbi iyingxubevange ehlanganisa insimbi nekhabhoni.Iphesenti lekhabhoni ensimbi lithinta ubulukhuni, amandla okunwebeka kanye ne-ductility ye-carbon steel.Ipayipi le-carbon steel engenamthungo noma ingot yensimbi eqinile yenziwa ngeshubhu le-capillary ngokusebenzisa imbobo, bese kwenziwa ucingo olugoqiwe olushisayo, olubandayo noma olubandayo.Ipayipi lensimbi elingenamthungo embonini yensimbi yaseChina linesikhundla esibalulekile.Impahla yepayipi lensimbi yensimbi engenamthungo iyishubhu eliyindilinga, imibungu yomshini wokusika amapayipi ukuze idlule ekusikeni okungaba ngu-1 m ubude, futhi ithunyelwe ukushisisa kwesithando somlilo sebhande elihambisayo.I-Billet ifakwa esithandweni sokushisa, izinga lokushisa lingaba ngu-1200 degrees Celsius.I-fuel i-hydrogen noma i-acetylene.Ukulawulwa kwezinga lokushisa kwesithando yinkinga eyinhloko.Ishubhu eliyindilinga laphuma lizobhoboza umshini ngomfutho womoya.Ngokuvamile, i-punch ejwayelekile kakhulu ingumshini wokubhoboza we-tapered roll, i-punch ephezulu yokukhiqiza, ikhwalithi yomkhiqizo, ukunwetshwa kwembobo enkulu, ingagqoka insimbi ehlukahlukene.Ukubhobozwa, ishubhu eliyindilinga bekulokhu kugingqika, ukugingqika noma ukuphuma.Ikhishwe kushubhu ngemuva kokulinganisa.Ukulinganisa ngezimbobo ze-rotary cone ezinesivinini esikhulu ku-billet ukuze kwakheke ishubhu.Ububanzi bepayipi ngomshini wokulinganisa ukuze kutholwe ubude bobubanzi bokubhoboza.Ngemva kwepayipi ngokulinganisa embhoshongweni wokupholisa, ukupholisa ngesifutho samanzi, insimbi emva kokupholisa, kufanele iqondiswe.Ngemuva kwebhande lensimbi elithunyelwe ngomshini wokuhlola insimbi yokuqondisa (noma ukuhlolwa kwengcindezi) ukuhlola kwangaphakathi.Uma ipayipi liqhekeka ngaphakathi, amabhamuza nezinye izinkinga zizotholwa.Ngemuva kwepayipi kodwa futhi ngokukhetha okuqinile kokulawulwa kwekhwalithi.Ikhwalithi yensimbi, ukusetshenziswa kwezinombolo zopende wesifutho, imininingwane, inombolo yenkatho yokukhiqiza.Nge-crane engena endlini yokugcina impahla.

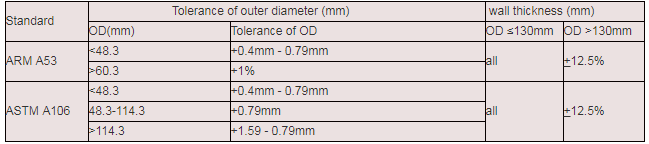

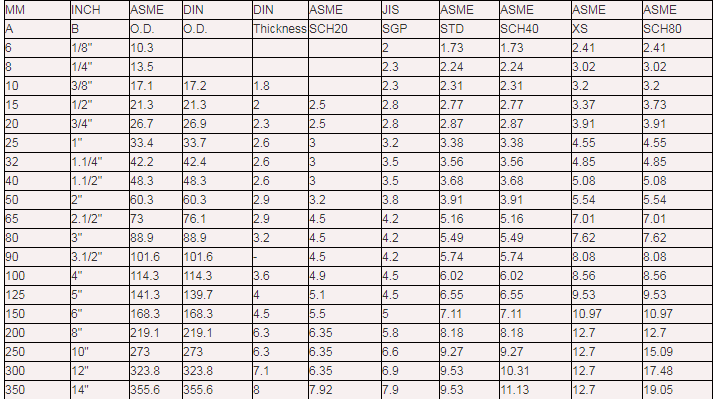

Ubukhulu bodonga lwepayipi elingenamthungo

Ukubekezelela Ububanzi Bangaphandle kanye Nokuqina Odongeni

| Okujwayelekile | Incazelo |

| I-ASTM A179/A179M | Isishintshi sokushisa esingenamthungo sensimbi esingenamthungo kanye namashubhu e-condenser. |

| I-API 5L | Ipayipi lomugqa. |

| I-ASTM A53M | Iphayiphu Lensimbi Elimnyama Nezinc Elihlanganisiwe futhi Elingenamthungo. |

| I-ASTM A106M | Ipayipi lensimbi ye-Seamless yesevisi yokushisa okuphezulu. |

| I-ASTM A105M | I-Carbon steel forgings yezinhlelo zokusebenza zamapayipi. |

| I-ASTM A234M | Ukufakwa kwamapayipi ensimbi eyenziwe nge-carbon steel ne-alloy steel yesevisi yezinga lokushisa elimaphakathi neliphezulu. |

| I-ASTM 3799 | Izinsimbi zamapayipi ensimbi, izikulufu kanye nokushisela kwesokhethi embonini ye-petroleum. |

| AS 1163 | Izingxenye ezingenalutho zensimbi yesakhiwo |

| AS 1074 | Amashubhu ensimbi namashubhu esevisi evamile |

| BS13872 | Amashubhu ensimbi ayisikulufa futhi anezisekelo namashubhu |

| Okujwayelekile | Uhlobo lwepayipi | Ikilasi | Ibanga |

| I-API SPEC 5L ISO 3183 | I-SMLS | I-PLS1 | L245B, L290 X42, L320 X46 , L360 X52, L390 X56, L415 X60, L450 X65, L485 X70 |

| I-PLS2 | I-L245N BN, L290N X42N, L320N X46N, L360N X52N, L390N X56N, L415N X60N, L360Q X52Q, L390Q X56Q, L415Q X60Q , L485Q X70Q

| ||

| I-PLS2 Imvelo Emuncu | L245NS BNS, L290NS X42NS, L320NS X46NS L360NS X52NS, L390NS X56NS, L415NS X60NS, L360QS X52QS, L390QS X56QS, L415QS X60QS L485QS X70QS

| ||

| WELD | I-PLS1 | L245B, L290 X42, L320 X46, L360 X52 L390 X56, L415 X60, L450 X65, L485 X70 | |

| I-PLS2 | L245M BM, L290M X42M, L320M X46M, L360M X52M, L390M X56M, L415M X60M, L450M X65M, L485M X70M, L555M X80M, | ||

| Okujwayelekile | Ibanga |

| I-ASTM A 53 M | A, B |

| I-ASTM A 106M | A, B, C |

| I-JIS G 3454 | I-STPG 370, STPG 410 |

| I-JIS G 3455 | STPG370, STPG410, STPG480 |

| I-JIS G 3456 | STPG370, STPG410, STPG480 |

Ibanga: Ukwakheka Kwekhemikhali (%):

| Okujwayelekile | Ibanga | C | Si | Mn | P | S | Ni | Cr | Cu | Mo | V |

| I-ASTMA 53M | A | ≤0.25 | - | ≤0.95 | ≤0.05 | ≤0.045 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 |

| B | ≤0.30 | - | ≤1.20 | ≤0.05 | ≤0.045 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| I-ASTM A 106M | A | ≤0.25 | ≥0.10 | 0.27-0.93 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 |

| B | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| C | ≤0.35 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| I-JIS G 3454 | I-STPG 370 | ≤0.25 | ≤0.35 | 0.30-0.90 | ≤0.040 | ≤0.040 | - | - | - | - | - |

| I-STPG 410 | ≤0.30 | ≤0.35 | 0.30-1.00 | ≤0.040 | ≤0.040 | - | - | - | - | - | |

| I-JIS G 3455 | I-STS 370 | ≤0.25 | 0.10-0.35 | 0.30-1.10 | ≤0.035 | ≤0.035 | - | - | - | - | - |

| I-STS 410 | ≤0.30 | 0.10-0.35 | 0.30-1.40 | ≤0.035 | ≤0.035 | - | - | - | - | - | |

| I-STS 480 | ≤0.33 | 0.10-0.35 | 0.30-1,50 | ≤0.035 | ≤0.035 | - | - | - | - | - | |

| I-JIS G 3456 | Isinyathelo 370 | ≤0.25 | 0.10-0.35 | 0.30-0.90 | ≤0.035 | ≤0.035 | - | - | - | - | - |

| I-STPT 410 | ≤0.30 | 0.10-0.35 | 0.30-1.00 | ≤0.035 | ≤0.035 | - | - | - | - | - | |

| Isinyathelo 480 | ≤0.33 | 0.10-0.35 | 0.30-1.00 | ≤0.035 | ≤0.035 | - | - | - | - | - |

Ukwelashwa okungaphezulu kwepayipi lensimbi: Ukuze kuthuthukiswe impilo yesevisi yepayipi likawoyela, ukwelashwa kwendawo ngokuvamile kuyenziwa ukuze kube lula ukuhlanganiswa okuqinile kwepayipi lensimbi kanye ne-anticorrosive coating. Izindlela zokucubungula ezivamile yilezi: ukuhlanza, ukuchithwa kwamathuluzi, ukuchotshozwa, ukuqhunyiswa kokudubula. izigaba ezine.I-1 yokuhlanza Amafutha, uthuli, i-lubricant, i-organic matter enamathela phezu kwepayipi lensimbi, ngokuvamile isebenzisa i-solvent, i-emulsion ukuhlanza indawo. izindlela zokwelapha ziyadingeka.Ukususwa kokugqwala kwethuluziIpayipi lensimbi elingaphezulu kwe-oxide, ukugqwala, i-welding slag, lingasebenzisa ibhulashi lensimbi yensimbi ukuze lihlanze futhi lipholishe indawo yokwelapha.Ukukhipha ithuluzi kungahlukaniswa kube imanuwali namandla, ithuluzi lemanuwali derusting lingafinyelela ku-Sa 2 level, amandla ukuchithwa kwethuluzi kungafinyelela izinga le-Sa3. Uma ubuso bepayipi lensimbi buhlanganiswe nesikhumba esiqinile se-oxide, kungase kungenzeki ukususa ukugqwala ngosizo lwamathuluzi, ngakho-ke sidinga ukuthola ezinye izindlela.3 pickling Izindlela ezivamile zokukhetha zihlanganisa ikhemistri kanye ne-electrolysis.Kodwa ukucotshwa kwamakhemikhali kuphela okusetshenziselwa ukuvikela ukugqwala kwepayipi.Ukucosha ngamakhemikhali kungafinyelela izinga elithile lokuhlanzeka kanye nokubamadlakela ebusweni bepayipi lensimbi, elilungele imigqa yehange elandelayo.Ngokuvamile njenge-a ukudubula (isihlabathi) ngemva kokucubungula kabusha.4 shot ukuqhuma ukuze kukhishwe ukugqwalaNgenjini enamandla amakhulu ukushayela ama-blades azungezayo anesivinini esikhulu, igrit yensimbi, isibhamu sensimbi, ingxenye, amaminerali nolunye izintambo ezilumayo ngaphansi kokusebenza kwamandla aphakathi nendawo kusifutho sepayipi lensimbi kanye nokukhishwa okukhulu, susa ukugqwala, ama-oxide. kanye nokungcola ngakolunye uhlangothi, ngakolunye uhlangothi, ipayipi lensimbi ngaphansi kwesenzo somthelela wodlame olubi namandla okungqubuzana, ukuze kuzuzwe ubulukhuni obufanayo obudingekayo.Phakathi kwezindlela ezine zokwelapha, ukudubula ukuqhuma nokususa kuyindlela ekahle yokwelapha yokususa ipayipi.Ngokuvamile, ukuqhunyiswa kwesibhamu kanye nokususa insimbi kusetshenziselwa ikakhulukazi ukwelashwa kwendawo yangaphakathi yepayipi lensimbi, futhi ukudubula nokususa ipayipi kusetshenziswa kakhulu ukwelapha ngaphandle kwepayipi lensimbi.

Futha ngopende

Futha ngopende

Ukupakisha okungangeni manzi