Paipu Pahu ʻole

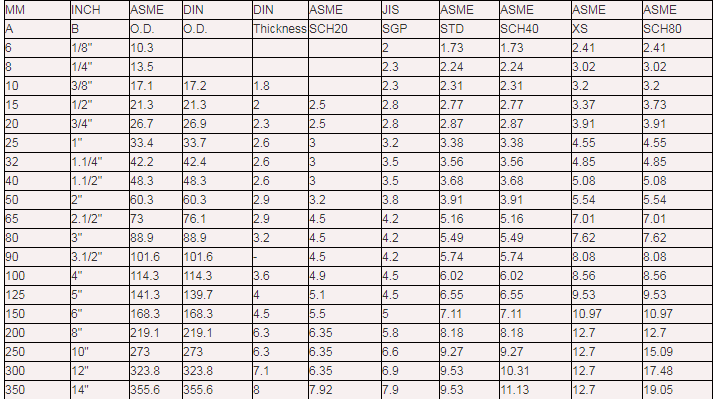

Hana ʻia ʻo Seamless Steel Pipe mai ke kila poepoe paʻa'billet'ʻo ia ka mea i hoʻomehana ʻia a hoʻokuʻu ʻia a huki ʻia paha ma luna o kahi ʻano a hiki i ke ʻano o ke kila i loko o kahi paipu puka.Hoʻopau ʻia ka paipu seamless i nā kikoʻī a me ka mānoanoa o ka paia i nā nui mai 1/8 iniha a 32 iniha OD.ʻO Carbon Steel Seamless Pipes / Tubes ʻO ke kila kila he mea hao i loko o ka hao a me ke kalapona.ʻO ka pākēneka o ke kalapona i ke kila e pili ana i ka paʻakikī, ka ikaika o ka elasticity a me ka ductility o ke kila kalapona.Hana ʻia ka paipu kila kalapona maʻemaʻe a i ʻole ke kila paʻa i ka pahu capillary ma o ka lua, a laila ma o ke kelepona wela, ʻōwili ʻia a i ʻole ke anu.He kūlana koʻikoʻi ko ka paipu kalapona kalapona ma ka ʻoihana kila o Kina.Seamless kalapona kila paipu mea he poepoe paipu, paipu oki mīkini embryos e hele ma ka oki ana ma kahi o 1 m o ka lōʻihi blank, a hoʻouna 'ia e conveyor kāʻei kapuahi wela.Hāʻawi ʻia ʻo Billet i loko o ka umu wela, ʻo ka mahana ma kahi o 1200 degere Celsius.He hydrogen a acetylene paha ka wahie.ʻO ka mālama ʻana i ka wela o ka umu ke kumu nui.Puka mai ka paipu poepoe e ku'i i ka mīkini ma ke kaomi ea.ʻO ka maʻamau maʻamau ʻoi aku ka tapered roll perforation machine, ka punch kiʻekiʻe o ka hana ʻana i ka maikaʻi, ka maikaʻi o ka huahana, ka hoʻonui ʻana o ka puka anawaena, hiki ke komo i nā ʻano kila.Perforation, poepoe paipu ua ma luna o ekolu-roll kea olokaa, olokaa a extrusion.ʻOki ʻia ka paipu ma hope o ka nui ʻana.ʻO ka hoʻopaʻa ʻana i nā lua i loko o ka billet e hana i kahi paipu.ʻO ke anawaena paipu e ka wili nui e hoʻoholo ai i ka lōʻihi o ke anawaena drill.Ma hope o ka paipu ma o ka nui ʻana i loko o ka hale hoʻoluʻu, e hoʻomaʻamaʻa ʻia e ka wai e hoʻoheheʻe ʻia, ke kila ma hope o ka hoʻoilo, pono e hoʻopololei.Ma hope o ke kāʻei kila i hoʻouna ʻia e ka mīkini hoʻāʻo metala (a i ʻole ka hoʻāʻo kaomi) no ka hoʻāʻo kūloko.Inā nahā ka paipu i loko, e ʻike ʻia nā ʻōpū a me nā pilikia ʻē aʻe.Ma hope o ka paipu akā ma o ke koho ʻana i ka manual quality control.ʻO ka maikaʻi kila, ka hoʻohana ʻana i nā helu pena spray, nā kikoʻī, ka helu hailona hana.Ma ka crane i loko o ka hale kūʻai.

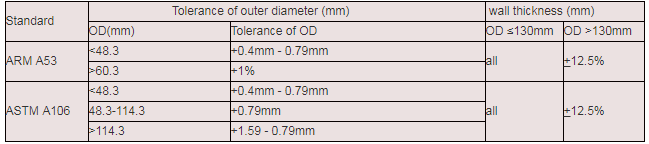

ʻO ka mānoanoa o ka pā o ka paipu ʻole

ʻO ka hoʻomanawanui o ka anawaena waho a me ka mānoanoa o ka pā

| Kūlana | wehewehe |

| ASTM A179/A179M | He mea hoʻololi wela mehana hoʻoheheʻe haʻahaʻa i huki ʻia i ke anu a me nā paipu condenser. |

| API 5L | Paipu laina. |

| ASTM A53M | ʻEleʻele a me Zinc i uhi ʻia i ka huila a me ka maʻemaʻe. |

| ASTM A106M | ʻO ka paipu kila carbon seamless no ka lawelawe wela kiʻekiʻe. |

| ASTM A105M | ʻO nā kalapona kalapona no ka hoʻohana ʻana i ka paipu. |

| ASTM A234M | ʻO nā paipu paipu o ke kila kalapona i hana ʻia a me ke kila kila no ka lawelawe wela haʻahaʻa a kiʻekiʻe. |

| ASTM 3799 | ʻO nā lako paipu kila, nā wili a me nā kumu hoʻoheheʻe no ka ʻoihana ʻaila. |

| AS 1163 | Nā ʻāpana hollow kila kila |

| AS 1074 | ʻO nā paipu kila a me nā tubular no ka lawelawe maʻamau |

| BS13872 | ʻO nā paipu kila wili a me nā kumu |

| Kūlana | ʻAno paipu | Papa | Papa |

| API SPEC 5L ISO 3183 | SMLS | PLS1 | L245B, L290 X42, L320 X46 , L360 X52, L390 X56, L415 X60, L450 X65, L485 X70 |

| PLS2 | L245N BN, L290N X42N, L320N X46N, L360N X52N, L390N X56N, L415N X60N, L360Q X52Q, L390Q X56Q, L415Q X60Q , L485Q X70Q

| ||

| PLS2 Sour Environment | L245NS BNS, L290NS X42NS, L320NS X46NS L360NS X52NS, L390NS X56NS, L415NS X60NS, L360QS X52QS, L390QS X56QS, L415QS X60QS L485QS X70QS

| ||

| WELD | PLS1 | L245B, L290 X42, L320 X46, L360 X52 L390 X56, L415 X60, L450 X65, L485 X70 | |

| PLS2 | L245M BM, L290M X42M, L320M X46M, L360M X52M, L390M X56M, L415M X60M, L450M X65M, L485M X70M, L555M X80M, | ||

| Kūlana | Papa |

| ASTM A 53 M | A , B |

| ASTM A 106M | A, B, C |

| JIS G 3454 | STPG 370, STPG 410 |

| JIS G 3455 | STPG370, STPG410, STPG480 |

| JIS G 3456 | STPG370, STPG410, STPG480 |

Papa: Huina Kemika (%):

| Kūlana | Papa | C | Si | Mn | P | S | Ni | Cr | Cu | Mo | V |

| ASTMA 53M | A | ≤0.25 | - | ≤0.95 | ≤0.05 | ≤0.045 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 |

| B | ≤0.30 | - | ≤1.20 | ≤0.05 | ≤0.045 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| ASTM A 106M | A | ≤0.25 | ≥0.10 | 0.27-0.93 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 |

| B | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| C | ≤0.35 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| JIS G 3454 | STPG 370 | ≤0.25 | ≤0.35 | 0.30-0.90 | ≤0.040 | ≤0.040 | - | - | - | - | - |

| STPG 410 | ≤0.30 | ≤0.35 | 0.30-1.00 | ≤0.040 | ≤0.040 | - | - | - | - | - | |

| JIS G 3455 | STS 370 | ≤0.25 | 0.10-0.35 | 0.30-1.10 | ≤0.035 | ≤0.035 | - | - | - | - | - |

| STS 410 | ≤0.30 | 0.10-0.35 | 0.30-1.40 | ≤0.035 | ≤0.035 | - | - | - | - | - | |

| STS 480 | ≤0.33 | 0.10-0.35 | 0.30-1.50 | ≤0.035 | ≤0.035 | - | - | - | - | - | |

| JIS G 3456 | STPT 370 | ≤0.25 | 0.10-0.35 | 0.30-0.90 | ≤0.035 | ≤0.035 | - | - | - | - | - |

| STPT 410 | ≤0.30 | 0.10-0.35 | 0.30-1.00 | ≤0.035 | ≤0.035 | - | - | - | - | - | |

| STPT 480 | ≤0.33 | 0.10-0.35 | 0.30-1.00 | ≤0.035 | ≤0.035 | - | - | - | - | - |

Ka mālama ʻana o ka paipu kila: I mea e hoʻomaikaʻi ai i ke ola lawelawe o ka pipeline aila, hana maʻamau ka mālama ʻana i ka ʻili e hoʻomaʻamaʻa i ka hui paʻa o ka paipu kila a me ka uhi anticorrosive. ʻehā ʻāpana.1 hoʻomaʻemaʻe ʻO ka momona, ka lepo, ka lubricant, nā mea organik i hoʻopili ʻia ma ka ʻili o ka paipu kila, e hoʻohana pinepine i ka solvent, emulsion e hoʻomaʻemaʻe i ka ʻili. pono ka lapaʻau 'ano hana.Tool rust removalSteel paipu ili oxide, rust, welding slag, hiki ke hoʻohana i ke kila uea palaki e hoʻomaʻemaʻe a me ka poli i ka ili treatment.Tool derusting hiki ke maheleia i ka manual a me ka mana, manual mea paahana derusting hiki ke hiki i Sa 2 pae, mana. hiki ke hoʻopau i ka mea hana i ka pae Sa3. Inā pili ka ʻili o ka paipu kila me kahi ʻili oxide ikaika loa, ʻaʻole hiki ke wehe i ka ʻōpala me ke kōkua o nā mea hana, no laila pono mākou e ʻimi i nā ala ʻē aʻe.3 pickling ʻO nā ʻano pickling maʻamau ka kemika a me ka electrolysis. Akā ʻo ka pickling kemika wale nō i hoʻohana ʻia no ka pale ʻana i ka corrosion pipeline. Hiki i ka pickling kemika ke hoʻokō i kahi degere o ka maʻemaʻe a me ka ʻawaʻawa ma ka ʻili o ka paipu kila, kahi kūpono no nā laina heleuma ma hope. pana (sand) ma hope o ka hana hou ʻana.4 pana ʻana no ka hoʻohemo ʻana i ka ʻōpalaMa o ka mana kiʻekiʻe e hoʻokele i ka wikiwiki o ka ʻili ʻana i nā lau, ke kila kila, ka pana kila, ka ʻāpana, nā minelala a me nā uea abrasive ʻē aʻe ma lalo o ka hana o ka ikaika centrifugal ma luna o ka paila kila a me ka ejection nui, e wehe pono i ka ʻōpala, oxides. a me ka lepo ma kekahi lima, ma ka lima 'ē aʻe, kila paipu ma lalo o ka hana o ka abrasive violent hopena a me friction ikaika, e hoʻokō i ka pono like roughness.Among na eha lapaʻau kaʻina hana, pana blasting a me ka derusting mea he kūpono lapaʻau ala no ka paipu derusting.ʻO ka maʻamau, hoʻohana nui ʻia ka puhi ʻana a me ka derusting no ka mālama ʻana i ka ʻili o loko o ka paipu kila, a ʻo ka puhi ʻana a me ka derusting i hoʻohana nui ʻia no ka mālama ʻana i waho o ka paipu kila.

Pepa pena

Pepa pena

Puke wai