Tubería sin costura de acero al carbono

La tubería de acero sin costura está hecha de acero redondo sólido.'palanquilla'que se calienta y se empuja o tira sobre un molde hasta que el acero adquiere la forma de un tubo hueco.Luego, la tubería sin costura se termina según las especificaciones dimensionales y de espesor de pared en tamaños desde 1/8 de pulgada hasta 32 pulgadas de diámetro externo.Tubos/tubos sin costura de acero al carbono El acero al carbono es una aleación compuesta de hierro y carbono.El porcentaje de carbono en el acero afecta la dureza, la resistencia a la elasticidad y la ductilidad del acero al carbono.Se fabrica una tubería de acero al carbono sin costura o un lingote de acero sólido a partir del tubo capilar a través del orificio, luego se realiza el proceso laminado en caliente, laminado en frío o en frío.Los tubos de acero al carbono sin costura ocupan una posición importante en la industria siderúrgica de China.El material de tubería de acero al carbono sin costura es un tubo redondo, los embriones de la máquina cortadora de tuberías se cortan aproximadamente 1 m de longitud en blanco y se envían mediante calentamiento por horno con cinta transportadora.La palanquilla se introduce en el horno de calentamiento, cuya temperatura es de unos 1200 grados Celsius.El combustible es hidrógeno o acetileno.El control de la temperatura del horno es la cuestión clave.El tubo redondo salió para perforar la máquina mediante presión de aire.Generalmente, el punzón más común es la máquina perforadora de rodillos cónicos, el punzón tiene una alta eficiencia de producción, calidad del producto, expansión del orificio de gran diámetro y puede usar una variedad de acero.La perforación, el tubo redondo se ha realizado mediante laminado transversal, laminado o extrusión de tres rodillos.Exprimido del tubo después del dimensionamiento.Dimensionado mediante cono giratorio de alta velocidad, taladre agujeros en el tocho para formar un tubo.Diámetro de la tubería mediante el molino dimensionador para determinar la longitud del diámetro de perforación.Después de que la tubería pase por el dimensionamiento hasta la torre de enfriamiento, se debe enderezar el acero después del enfriamiento mediante pulverización de agua.Después de que la correa de acero se envíe mediante una máquina de prueba de metal enderezadora (o prueba de presión) para pruebas internas.Si la tubería tiene grietas internas, se detectarán burbujas y otros problemas.Después de la tubería, sino también mediante una estricta selección manual de control de calidad.Calidad del acero, número de uso de pintura en aerosol, especificaciones, número de lote de producción.Mediante grúa hasta el almacén.

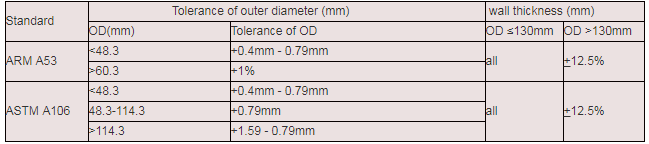

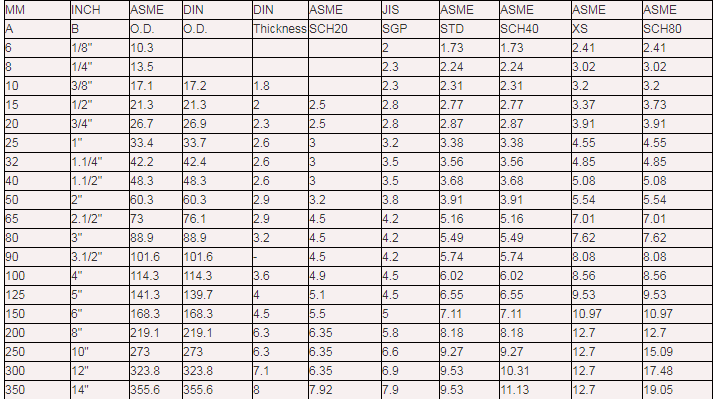

El espesor de pared de la tubería sin costura.

Tolerancia del diámetro exterior y el espesor de la pared.

| Estándar | Descripción |

| ASTM A179/A179M | Tubos de intercambiador de calor y condensador de acero de baja aleación estirado en frío sin soldadura. |

| API 5L | Tuberia. |

| ASTM A53M | Tubería de acero soldada y sin costura recubierta de zinc y negro. |

| ASTM A106M | Tubería de acero al carbono sin costura para servicio a alta temperatura. |

| ASTM A105M | Piezas forjadas de acero al carbono para aplicaciones de tuberías. |

| ASTM A234M | Accesorios de tubería de acero al carbono forjado y acero aleado para servicio a temperatura moderada y alta. |

| ASTM 3799 | Accesorios para tuberías de acero, soldabilidad roscada y encaje para la industria petrolera. |

| COMO 1163 | Secciones huecas de acero estructural |

| COMO 1074 | Tubos y tubulares de acero para servicio ordinario |

| BS13872 | Tubos y tubulares de acero atornillados y encajados |

| Estándar | tipo de tubería | Clase | Calificación |

| ESPECIFICACIÓN API 5L ISO 3183 | SMLS | PLS1 | L245B, L290 X42, L320 X46, L360 X52, L390 X56, L415 X60, L450 X65, L485 X70 |

| PLS2 | L245N BN, L290N X42N, L320N X46N, L360N X52N, L390N X56N, L415N X60N, L360Q X52Q, L390Q X56Q, L415Q X60Q, L485Q X70Q

| ||

| PLS2 Ambiente ácido | L245NS BNS, L290NS X42NS, L320NS X46NS L360NS X52NS, L390NS X56NS, L415NS X60NS, L360QS X52QS, L390QS X56QS, L415QS X60QS L485QS X70QS

| ||

| SOLDAR | PLS1 | L245B, L290 X42, L320 X46, L360 X52 L390 X56, L415 X60, L450 X65, L485 X70 | |

| PLS2 | L245M BM, L290M X42M, L320M X46M, L360M X52M, L390M X56M, L415M X60M, L450M X65M, L485M X70M, L555M X80M, | ||

| Estándar | Calificación |

| ASTM A 53M | A, B |

| ASTM A 106M | A B C |

| JIS G 3454 | STPG 370, STPG 410 |

| JIS G 3455 | STPG370, STPG410, STPG480 |

| JIS G 3456 | STPG370, STPG410, STPG480 |

Calificación: Composición química (%):

| Estándar | Calificación | C | Si | Mn | P | S | Ni | Cr | Cu | Mo | V |

| ASTMA 53M | A | ≤0,25 | - | ≤0,95 | ≤0,05 | ≤0,045 | ≤0,40 | ≤0,40 | ≤0,40 | ≤0,15 | ≤0,08 |

| B | ≤0,30 | - | ≤1,20 | ≤0,05 | ≤0,045 | ≤0,40 | ≤0,40 | ≤0,40 | ≤0,15 | ≤0,08 | |

| ASTM A 106M | A | ≤0,25 | ≥0,10 | 0,27-0,93 | ≤0,035 | ≤0,035 | ≤0,40 | ≤0,40 | ≤0,40 | ≤0,15 | ≤0,08 |

| B | ≤0,30 | ≥0,10 | 0,29-1,06 | ≤0,035 | ≤0,035 | ≤0,40 | ≤0,40 | ≤0,40 | ≤0,15 | ≤0,08 | |

| C | ≤0,35 | ≥0,10 | 0,29-1,06 | ≤0,035 | ≤0,035 | ≤0,40 | ≤0,40 | ≤0,40 | ≤0,15 | ≤0,08 | |

| JIS G 3454 | STGP 370 | ≤0,25 | ≤0,35 | 0,30-0,90 | ≤0,040 | ≤0,040 | - | - | - | - | - |

| STGP 410 | ≤0,30 | ≤0,35 | 0,30-1,00 | ≤0,040 | ≤0,040 | - | - | - | - | - | |

| JIS G 3455 | SAS 370 | ≤0,25 | 0,10-0,35 | 0,30-1,10 | ≤0,035 | ≤0,035 | - | - | - | - | - |

| STS 410 | ≤0,30 | 0,10-0,35 | 0,30-1,40 | ≤0,035 | ≤0,035 | - | - | - | - | - | |

| SAS 480 | ≤0,33 | 0,10-0,35 | 0,30-1,50 | ≤0,035 | ≤0,035 | - | - | - | - | - | |

| JIS G 3456 | STPT 370 | ≤0,25 | 0,10-0,35 | 0,30-0,90 | ≤0,035 | ≤0,035 | - | - | - | - | - |

| STPT 410 | ≤0,30 | 0,10-0,35 | 0,30-1,00 | ≤0,035 | ≤0,035 | - | - | - | - | - | |

| STPT 480 | ≤0,33 | 0,10-0,35 | 0,30-1,00 | ≤0,035 | ≤0,035 | - | - | - | - | - |

Tratamiento de la superficie de la tubería de acero: para mejorar la vida útil del oleoducto, generalmente se lleva a cabo un tratamiento de la superficie para facilitar la combinación firme de la tubería de acero y el revestimiento anticorrosivo. Los métodos de procesamiento comunes son: limpieza, desoxidación con herramientas, decapado, desoxidación con granalla. cuatro categorías.1 limpieza Grasa, polvo, lubricante, materia orgánica adherida a la superficie de la tubería de acero, generalmente usando solvente, emulsión para limpiar la superficie. Sin embargo, el óxido, la piel de óxido y la escoria de soldadura en la superficie de la tubería de acero no se pueden eliminar, por lo que otros Se necesitan métodos de tratamiento. Eliminación de óxido de herramientas. Óxido de la superficie de la tubería de acero, óxido, escoria de soldadura, puede usar un cepillo de alambre de acero para limpiar y pulir el tratamiento de la superficie. La eliminación de óxido de la herramienta se puede dividir en manual y eléctrica, la eliminación de óxido de la herramienta manual puede alcanzar el nivel Sa 2, potencia. La eliminación de óxido con herramientas puede alcanzar el nivel Sa3. Si la superficie de la tubería de acero está unida con una capa de óxido particularmente fuerte, puede ser imposible eliminar el óxido con la ayuda de herramientas, por lo que debemos encontrar otras formas.3 decapado Los métodos de decapado comunes incluyen la química y la electrólisis. Pero solo se utiliza el decapado químico para la protección contra la corrosión de las tuberías. El decapado químico puede lograr un cierto grado de limpieza y rugosidad en la superficie de la tubería de acero, lo cual es conveniente para líneas de anclaje posteriores. Generalmente como granalla (arena) después del reprocesamiento.4 granallado para la eliminación de óxido Mediante un motor de alta potencia, las cuchillas giratorias de alta velocidad, arena de acero, granalla de acero, segmentos, minerales y otros cables abrasivos bajo la acción de la fuerza centrífuga sobre la superficie de la tubería de acero se rocían y se expulsan en masa, eliminan completamente el óxido y los óxidos. y suciedad, por un lado, y, por el otro, tubos de acero bajo la acción de un impacto abrasivo violento y una fuerza de fricción, para lograr la rugosidad uniforme requerida. Entre los cuatro métodos de tratamiento, el granallado y la desoxidación son un método de tratamiento ideal para la desoxidación de tuberías.Generalmente, el granallado y la desoxidación se utilizan principalmente para el tratamiento de la superficie interior de tubos de acero, y el granallado y la desoxidación se utilizan principalmente para el tratamiento de la superficie exterior de tubos de acero.

Pintura en aerosol

Pintura en aerosol

Embalaje impermeable