Tuyaux en acier pour restes explosifs des guerres

(1) tube soudé provenant du soudage de plaques d'acier dans le tube rond, divisé en tube soudé par résistance à haute fréquence (tuyau soudé ERW), tube de soudage à l'arc à couture droite (LSAW), tube soudé en spirale. L'ingénierie électrique avec "SC", peut être utilisée car le tuyau de gaz d'eau peut également être utilisé comme tuyau de filetage, relativement épais.

(2) Le tuyau de pipeline, également connu sous le nom de tuyau métallique, est relativement fin, désigné par "T", et ne peut être utilisé que pour le filetage.Tuyau en acier ERWTuyau en acier ERW

(3) Le tube ERW est un "tube en acier de soudage par résistance à haute fréquence", et le processus de soudage commun est différent, la ligne de soudure provient du matériau de base du corps de la ceinture en acier fondu, la résistance mécanique est meilleure que celle du soudage général. pour le soudage par résistance, le soudage par résistance présente les caractéristiques d'une efficacité de production élevée, d'un faible coût, d'une économie de matériaux et d'une automatisation facile. Il est donc largement utilisé dans l'aviation, l'aérospatiale, l'énergie, l'électronique, l'automobile, l'industrie légère et d'autres secteurs industriels. procédés de soudage importants.

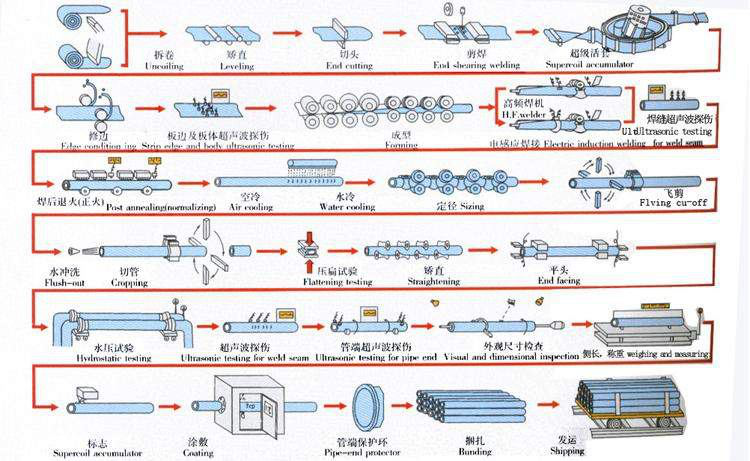

Processus de production des tuyaux en acier ERW :

Déroulage --- 2. Nivellement --- 3. Coupe d'extrémité --- 4. Soudage par cisaillement d'extrémité --- 5. Accumulateur de superbobine --- 6. Coupe de bord --- 7. Détection par ultrasons --- 8. Formage - -- 9. Soudage par induction électrique --- 10. Détection par ultrasons du cordon de soudure --- 11. Traitement thermique à moyenne fréquence --- 12. Refroidissement par air --- 13. Refroidissement par eau --- 14. Dimensionnement --- 15 Découpe à la volée --- 16. Rinçage --- 17. Recadrage --- 18. Test d'aplatissement --- 19. Redressage --- 20. Rabotage et chanfreinage --- 21. Test hydrodynamique --- 22 Détection par ultrasons du cordon de soudure --- 23. Détection par ultrasons de l'extrémité du tuyau --- 24. Inspection visuelle et dimensionnelle --- 25.Pesage et mesure --- 26. Marquage --- 27. Revêtement --- 28. Protection des extrémités de tuyaux --- 29. Cintrage --- 30. Expédition

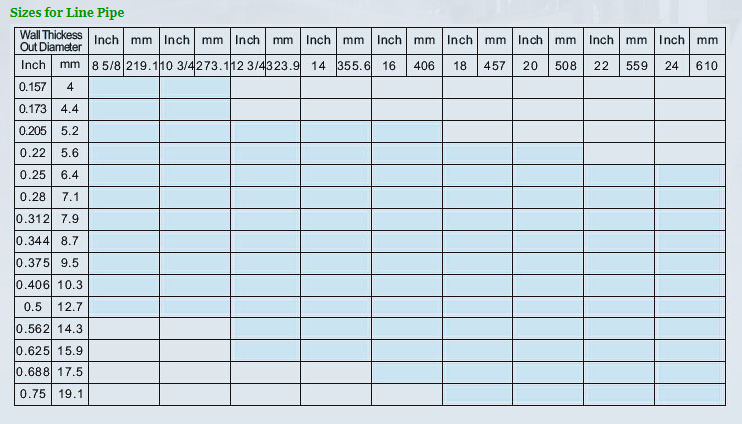

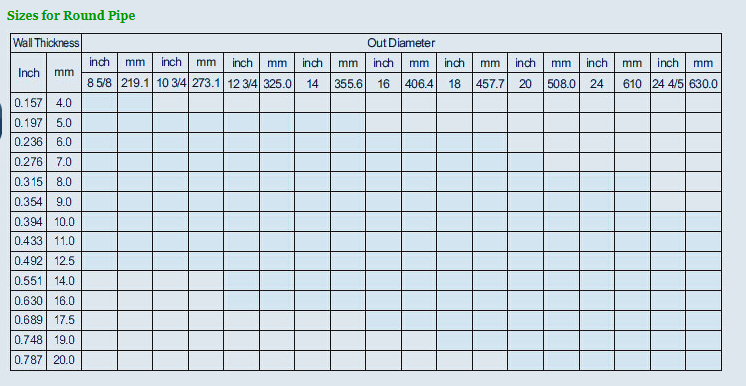

Dimensions, spécifications et tailles des tuyaux en acier ERW

| OD | WT | |||||||||||||||||||||||||

| Pouce | mm | Pouce | mm | Pouce | mm | Pouce | mm | Pouce | mm | Pouce | mm | Pouce | mm | Pouce | mm | Pouce | mm | Pouce | mm | Pouce | mm | Pouce | mm | Pouce | mm | |

| 0,157 | 4 | 0,173 | 4.4 | 0,205 | 5.2 | 0,22 | 5.6 | 0,25 | 6.4 | 0,28 | 7.1 | 0,312 | 7.9 | 0,344 | 8.7 | 0,375 | 9.5 | 0,406 | 10.3 | 0,5 | 12.7 | 0,562 | 14.3 | |||

| 8 5/8 | 219.1 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 10 3/4 | 273.1 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 12 3/4 | 323,9 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 14 | 355,6 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 16 | 406 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 18 | 457 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 20 | 508 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 10022 | 559 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 241 | 610 |

|

|

|

|

|

|

|

|

|

|

| ||||||||||||||

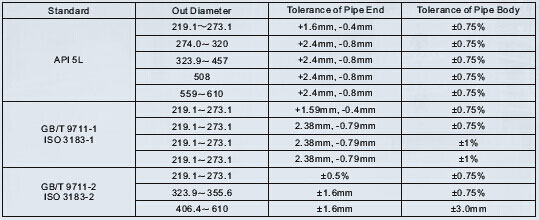

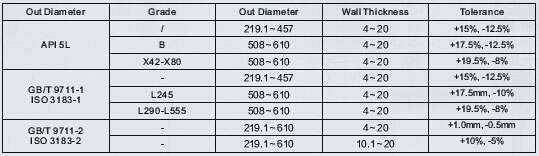

Tolérances de diamètre extérieur – Tuyaux en acier ERW

Tolérances d'épaisseur de paroi - Tuyaux en acier ERW

Légèrement huilé, galvanisé à chaud, électrozingué, noir, nu, revêtement vernis/huile antirouille, revêtements protecteurs