ERW-Stahlrohr

(1) Geschweißtes Rohr aus Stahlblech, das in ein rundes Rohr geschweißt wird, unterteilt in hochfrequenzgeschweißte Rohre (ERW-geschweißte Rohre), gerade Naht-Lichtbogenschweißrohre (LSAW) und spiralgeschweißte Rohre. Elektrotechnik mit „SC“ kann verwendet werden Als Wassergasrohr kann es auch als Gewinderohr verwendet werden, relativ dick.

(2) Rohrleitungsrohre, auch Drahtrohre genannt, sind relativ dünn, werden mit „T“ bezeichnet und können nur zum Gewindeschneiden verwendet werden.ERW-StahlrohrERW-Stahlrohr

(3) ERW-Rohr ist ein „Hochfrequenz-Widerstandsschweiß-Stahlrohr“, und das übliche Schweißverfahren ist unterschiedlich, die Schweißnaht besteht aus dem Grundmaterial des geschmolzenen Stahlbandkörpers, die mechanische Festigkeit ist besser als beim allgemeinen Schweißen. ERW steht Beim Widerstandsschweißen zeichnet sich das Widerstandsschweißen durch hohe Produktionseffizienz, niedrige Kosten, Materialeinsparung und einfache Automatisierung aus und wird daher häufig in der Luft- und Raumfahrt, Energie, Elektronik, Automobilindustrie, Leichtindustrie und anderen Industriezweigen eingesetzt wichtige Schweißprozesse.

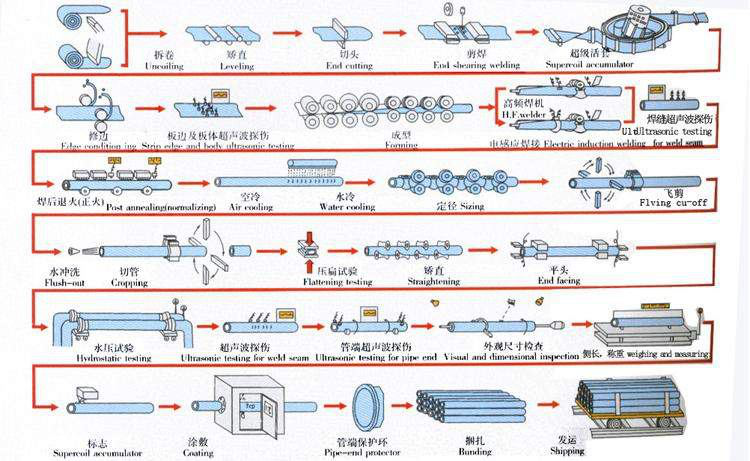

Produktionsprozess für ERW-Stahlrohre:

Abwickeln --- 2. Nivellieren --- 3. Endschneiden --- 4. Endscherschweißen --- 5. Supercoil-Akkumulator --- 6. Kantenschneiden --- 7. Ultraschallerkennung --- 8. Formen - -- 9. Elektrisches Induktionsschweißen --- 10. Ultraschallerkennung für Schweißnaht --- 11. Mittelfrequenz-Wärmebehandlung --- 12. Luftkühlung --- 13. Wasserkühlung --- 14. Dimensionierung --- 15 . Fliegendes Schneiden --- 16. Ausspülen --- 17. Beschneiden --- 18. Abflachungsprüfung --- 19. Richten --- 20. Endenbearbeitung und Abschrägung --- 21. Hydrodynamische Prüfung --- 22 . Ultraschallerkennung für Schweißnaht --- 23. Ultraschallerkennung für Rohrende --- 24. Sicht- und Maßkontrolle --- 25. Wiegen und Messen --- 26. Markieren --- 27. Beschichten --- 28. Rohrendenschutz --- 29. Biegen --- 30. Versand

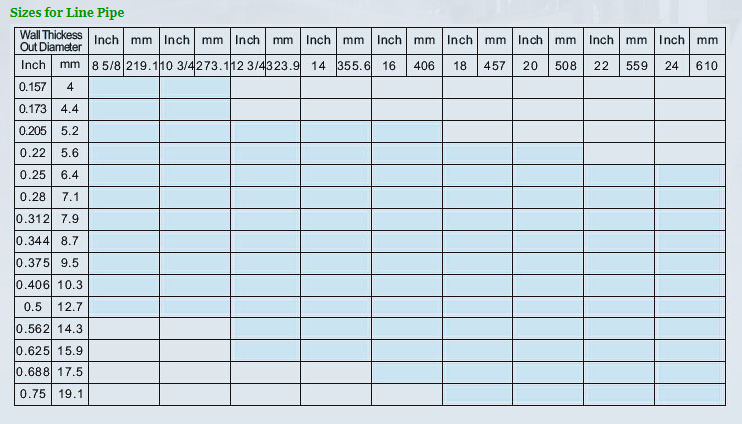

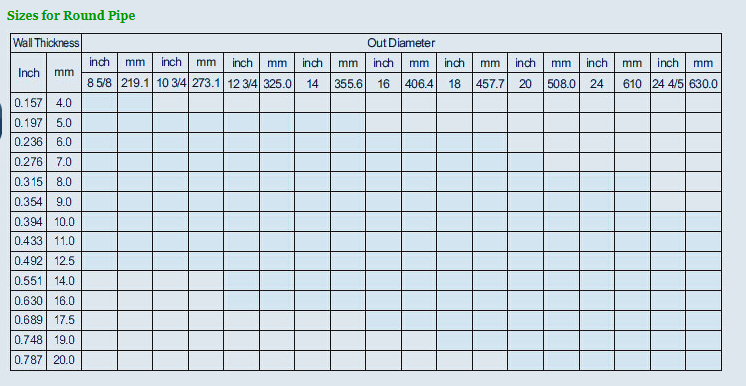

Abmessungen, Spezifikationen, Größen von ERW-Stahlrohren

| OD | WT | |||||||||||||||||||||||||

| Zoll | mm | Zoll | mm | Zoll | mm | Zoll | mm | Zoll | mm | Zoll | mm | Zoll | mm | Zoll | mm | Zoll | mm | Zoll | mm | Zoll | mm | Zoll | mm | Zoll | mm | |

| 0,157 | 4 | 0,173 | 4.4 | 0,205 | 5.2 | 0,22 | 5.6 | 0,25 | 6.4 | 0,28 | 7.1 | 0,312 | 7.9 | 0,344 | 8.7 | 0,375 | 9.5 | 0,406 | 10.3 | 0,5 | 12.7 | 0,562 | 14.3 | |||

| 8 5/8 | 219.1 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 10 3/4 | 273.1 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 12 3/4 | 323,9 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 14 | 355,6 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 16 | 406 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 18 | 457 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 20 | 508 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 10022 | 559 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 241 | 610 |

|

|

|

|

|

|

|

|

|

|

| ||||||||||||||

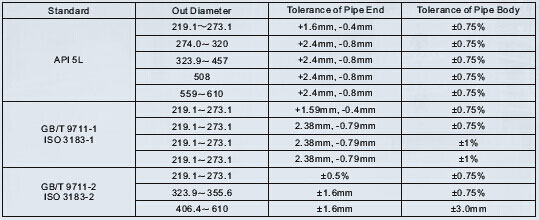

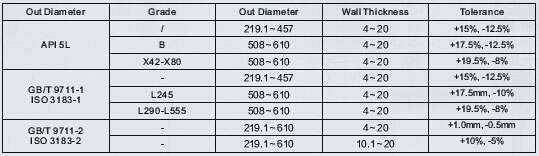

Toleranzen des Außendurchmessers – ERW-Stahlrohr

Toleranzen der Wandstärke – ERW-Stahlrohr

Leicht geölt, feuerverzinkt, elektroverzinkt, schwarz, blank, Lackbeschichtung/Rostschutzöl, Schutzbeschichtungen