Rostfreies nahtloses Rohr

Härte:

Zur Messung der Härte von Brinell, Rockwell und Vickers werden üblicherweise Edelstahlrohre verwendet.Brinell-Härte Unter den Edelstahlrohrnormen ist die Brinell-Härte die am weitesten verbreitete, und die Härte des Materials wird oft durch den Einkerbungsdurchmesser ausgedrückt, was sowohl intuitiv als auch praktisch ist.Für Stahlrohre aus härterem oder dünnerem Stahl ist es jedoch nicht geeignet.

Rockwell-Härte:

Der Rockwell-Härtetest für Edelstahlrohre ist derselbe wie der Brinell-Härtetest.Der Unterschied besteht darin, dass die Tiefe der Vertiefung gemessen wird.Der Rockwell-Härtetest ist eine weit verbreitete Methode, bei der HRC in Stahlrohrnormen nach der Brinell-Härte HB an zweiter Stelle steht.Die Rockwell-Härte kann zur Bestimmung von Metallmaterialien von extrem weich bis sehr hart angewendet werden.Es kompensiert die Brinell-Methode.Sie ist einfacher als die Brinell-Methode und kann den Härtewert direkt vom Zifferblatt der Härtemaschine ablesen.Aufgrund der geringen Einkerbung ist der Härtewert jedoch nicht so genau wie bei der Brinell-Methode.

Vickers-Härte

Der Vickers-Härtetest für Edelstahlrohre ist auch eine Eindruckprüfmethode zur Messung sehr dünner Metallmaterialien und der Oberflächenschichthärte.Sie verfügt über die Hauptvorteile der Brinell- und Rockwell-Methoden und überwindet deren grundlegende Nachteile, ist jedoch nicht so einfach wie die Rockwell-Methode.Die Vickers-Methode wird in Stahlrohrnormen selten verwendet.

Härtetest

Das Edelstahlrohr hat einen Innendurchmesser von 6,0 mm oder mehr und ein geglühtes Edelstahlrohr mit einer Wandstärke von 13 mm oder weniger.Es kann sich um einen Vickers-Härteprüfer vom Typ W-B75 handeln.Es ist sehr schnell und einfach zu prüfen und eignet sich für die schnelle und zerstörungsfreie Prüfung von Edelstahlrohren.Edelstahlrohre mit einem Innendurchmesser von mehr als 30 mm und einer Wandstärke von mehr als 1,2 mm werden mit einem Rockwell-Härteprüfgerät auf HRB- und HRC-Härte geprüft.Edelstahlrohre mit einem Innendurchmesser von mehr als 30 mm und einer Wandstärke von weniger als 1,2 mm werden mit einem Oberflächen-Rockwell-Härteprüfgerät zur Prüfung der HRT- oder HRN-Härte geprüft.Bei Edelstahlrohren mit einem Innendurchmesser von weniger als 0 mm und mehr als 4,8 mm wird die Härte von HR15T mit einem speziellen Rockwell-Härteprüfer für Rohre geprüft.Wenn der Innendurchmesser des Edelstahlrohrs größer als 26 mm ist, kann die Härte der Innenwand des Rohrs auch mit einem Ro geprüft werden

Chemische Zusammensetzung

| Noten | C max | Mn max | P max | S max | Si max | Cr | Ni | Mo |

| 304 | 0,08 | 2,00 | 0,04 | 0,03 | 0,075 | 18.00-20.00 Uhr | 8.00-11.00 Uhr | / |

| 304L | 0,035 | 2,00 | 0,04 | 0,03 | 0,075 | 18.00-20.00 Uhr | 8.00-13.00 Uhr | / |

| 316 | 0,08 | 2,00 | 0,04 | 0,03 | 0,075 | 16.00-18.00 Uhr | 11.00-14.00 Uhr | 2.00-3.00 |

| 316L | 0,035 | 2,00 | 0,04 | 0,03 | 0,075 | 16.00-18.00 Uhr | 10.00-15.00 Uhr | 2.00-3.00 |

Mechanische Eigenschaften

| Noten | Itemper | Zug-Psi | Ertrag Psi | Dehnung % | Rockwell-Härte |

| 304 | Geglüht | 85000-105000 | 35000-75000 | 20-55 | 80-95 |

| 304L | Geglüht I1/8 Schwer | 80000-105000 | 30000-75000 | 20-55 | 75-95 |

| 316 | Geglüht | 85000 Min | 35000 Min | 50 Min | 80 Min |

| Geglüht | 80000 Min | 30000 Min | 50 Min | 75 Min |

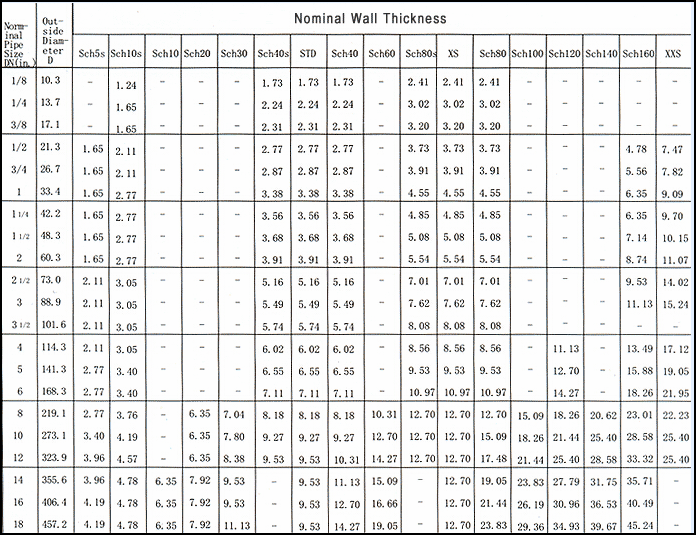

Größen von Edelstahlrohren

Geglüht und gebeizt, blankgeglüht, poliert

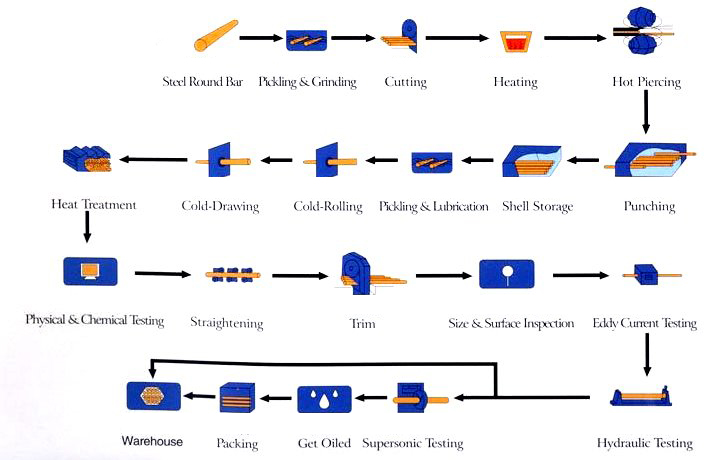

Verfahren