أنابيب المرجل

أنابيب الغلايات هي واحدة من الأنابيب غير الملحومة.طرق التصنيع هي نفس طريقة تصنيع الأنابيب غير الملحومة، ولكن لديها متطلبات صارمة لتصنيع الأنابيب الفولاذية.وفقًا لمستوى درجة الحرارة، ينقسم أنبوب الغلاية إلى أنابيب غلاية عامة وأنبوب غلاية عالي الضغط.

أساليب الانتاج:

① درجة حرارة أنبوب الغلاية العامة أقل من 450 درجة مئوية، وذلك باستخدام الأنابيب الفولاذية المدرفلة على الساخن أو الأنابيب المسحوبة على البارد.

② يتم استخدام أنبوب الغلاية عالي الضغط في كثير من الأحيان في ظروف ارتفاع درجة الحرارة وأنابيب الضغط العالي، وتأثير ارتفاع درجة حرارة غاز المداخن وبخار الماء، والأكسدة والتآكل.الأنابيب الفولاذية ذات قوة تمزق عالية، ومقاومة عالية لتآكل الأكسجين ولها استقرار تنظيمي جيد.

أغراض أنابيب الغلايات:

① تستخدم أنابيب الغلايات العامة بشكل أساسي لتصنيع أنابيب جدار الماء، وأنابيب الماء المغلي وأنابيب البخار فائقة السخونة، وأنابيب غلايات قاطرة البخار فائقة السخونة، وأنابيب الدخان الكبيرة والصغيرة وطوب قوس الأنابيب.

② أنبوب الغلايات عالي الضغط يستخدم بشكل رئيسي لتصنيع أنابيب السخان الفائق للغلايات ذات الضغط العالي والضغط العالي للغاية، وأنابيب إعادة التسخين، ومجرى الهواء، وأنابيب البخار الرئيسية.

فئة:

أنابيب الغلايات العامة وأنبوب الغلايات ذات الضغط العالي تتعرض أنابيب الغلايات لأداء درجات الحرارة العالية.يمكن تقسيم أنابيب الغلايات بشكل عام، أو أنابيب الغلايات ذات الضغط العالي حسب استخدامها إلى مجموعة متنوعة من الأنابيب الفولاذية.

تتوفر المعايير والمواد الخاصة بالأنابيب الفولاذية في مواد الكربون والسبائك والفولاذ المقاوم للصدأ.

الصلب الكربوني:ASTM/ASME A/SA 106، ASTM A179، ASTM A192، ASTM/ASME A/SA 210، ASTM A333 Gr 1، 6,7 إلى Gr 9،

خليط معدني:ASTM/ASME A/SA 213 T1، T2، T5، T9، T11، T12، T22، T91، T92؛أستم A335 P1، P2، P5، P9، P11، P12، P22، P91، P92

الفولاذ المقاوم للصدأ:ASTM A268، ASTM A213، TP304/L، TP316/L، 310S، 309S، 317،317L، 321،321H، ومواد الفولاذ المقاوم للصدأ المزدوجة وما إلى ذلك.

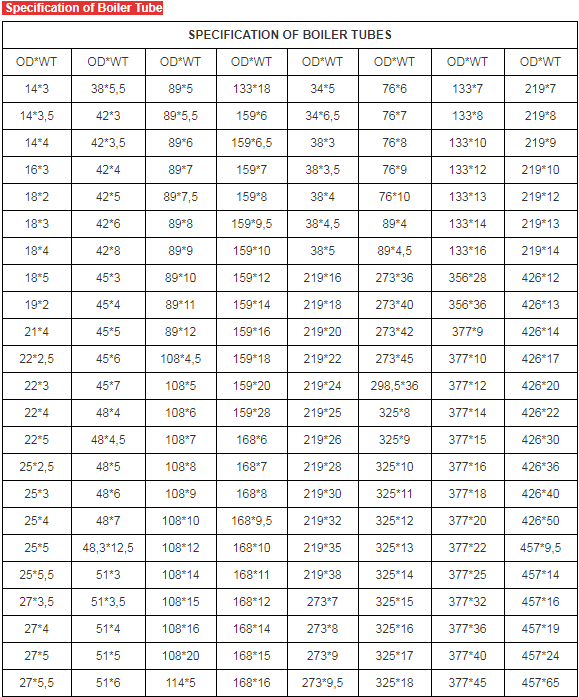

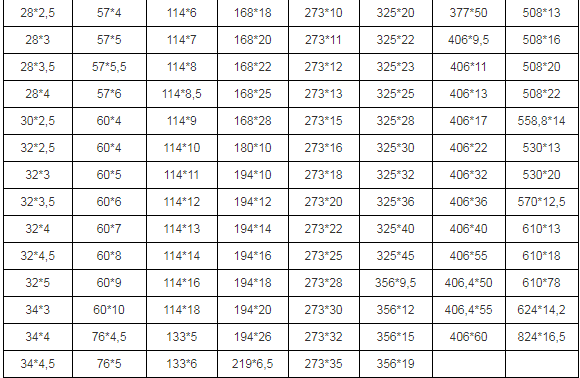

الأحجام المشتركة: OD من 6 مم إلى 1240 مم، سمك من 1 مم إلى 50 مم

الأنواع:أنبوب غلاية مستقيم، وأنابيب فولاذية على شكل U لحزمة مبادل الأنبوب.

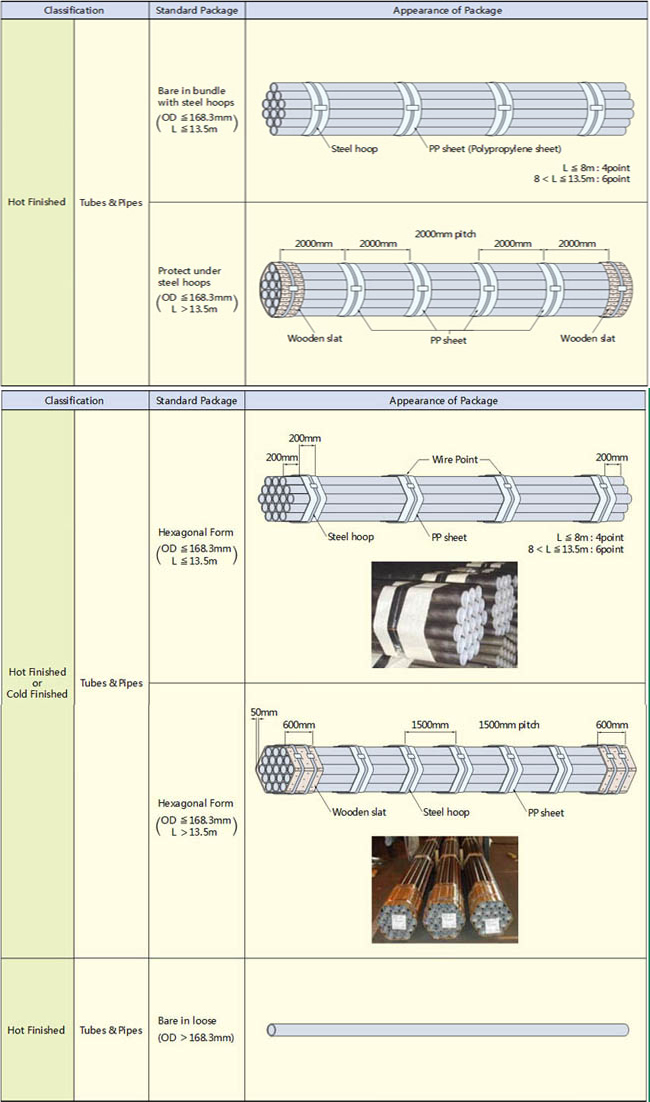

تحدد هذه المعايير التصنيف والحجم والشكل والوزن والانحراف المسموح به والمتطلبات الفنية والفحص والاختبار والتعبئة ووضع العلامات وشهادة الجودة للأنابيب الفولاذية غير الملحومة للغلاية.

المعايير:

GB (المعايير الوطنية الصينية)

(2) GB 5310: أنبوب فولاذي غير ملحوم لغلاية الضغط العالي

(3) GB 13296: أنابيب فولاذية غير ملحومة للغلايات والمبادلات الحرارية

(4) GB 6479: أنابيب فولاذية غير ملحومة لمعدات الأسمدة الكيماوية ذات الضغط العالي

(5) GB 9948: أنابيب فولاذية غير ملحومة لتكسير البترول

ASME (الجمعية الأمريكية للمهندسين الميكانيكيين)

(2) ASME SA-192M: أنابيب غلايات غير ملحومة من الفولاذ الكربوني للضغط العالي

(3) ASME SA-209M: غلاية غير ملحومة مصنوعة من سبائك الصلب والكربون والموليبدينوم وأنابيب التسخين الفائق

(4) ASME SA-210M: غلايات فولاذية متوسطة الكربون وأنابيب محمصة غير ملحومة

(5) ASME SA-213M: غلايات فولاذية غير ملحومة من سبائك الحديد والأوستنيتي، وأنابيب التسخين والمبادل الحراري

(6) ASME SA178: غلاية ومسخن فولاذي كربوني ملحوم بالمقاومة الكهربائية وفولاذ منغنيز الكربون

ASTM (المعايير الوطنية الصينية)

(2) SA213-T2: يحتوي ASME SA213 T2 على ضغوط مسموح بها تصل إلى 1000 فهرنهايت في كود غلاية ASME.

(3)SA213-T9

(4) SA213-T12: غلاية مصنوعة من سبائك الصلب الحديدي والأوستنيتي غير الملحومة، مسخن فائق، أنابيب مبادل حراري.

(5) SA213-T11: تستخدم الأنابيب في المبادلات الحرارية والسخانات الفائقة والغلايات.

(6) SA213-T22: أنبوب الغلاية ASM T22 عبارة عن أنبوب يتحمل درجات الحرارة العالية يستخدم في البيئات الحمضية والمسببة للتآكل مثل معالجة الهيدروكلوريك وفي محفز كلوريد الألومنيوم الذي يتضمن التطبيقات.

(7) ASTM A 106M: أنابيب الصلب الكربوني غير الملحومة للخدمة في درجات الحرارة العالية

(8) ASTM A192M: أنابيب غلايات من الصلب الكربوني غير الملحومة للضغط العالي

(9) ASTM A210M: غلايات فولاذية متوسطة الكربون غير ملحومة وأنابيب محمصة

(10) ASTM A 335M: أنابيب فولاذية من سبائك الحديد غير الملحومة للخدمة في درجات الحرارة العالية

EN 10216-2: أنابيب فولاذية غير ملحومة لأغراض الضغط

جيس

(1) JIS G3461: غلايات من الصلب الكربوني وأنابيب مبادل حراري

(2) JIS G3462: غلايات من سبائك الصلب وأنابيب مبادل حراري

(3) JIS G3463: الفولاذ المقاوم للصدأ لأنابيب الغلايات والمبادلات الحرارية

الفولاذ المقاوم للصدأ

SA213-T304:– تتكون مادة SA 213 Tp 304 من 18% من الكروم والكربون والمنغنيز والفوسفور والكبريت والسيليكون والنيكل في التركيبة.

SA213-T316:– أنبوب SA213 TP316 هو معيار المواد لأنابيب المبادلات الحرارية المصنوعة من الفولاذ المقاوم للصدأ الأوستنيتي 316.

SA213-TP321 و347– SA213 TP321 هي مواصفات أنابيب المبادلات الحرارية المصنوعة من الفولاذ المقاوم للصدأ الأوستنيتي 321.

عارية، مزيتة قليلاً، طلاء أسود/أحمر/أصفر، طلاء الزنك/مقاوم للتآكل

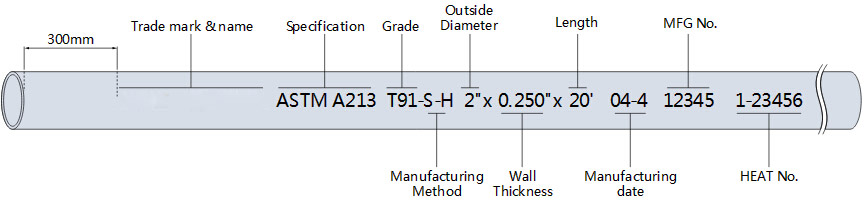

وضع العلامات القياسية