Duban Kayayyakin Bututu & Gwaji

A lokacin masana'antu daban-daban Dubawa & Gwaji ana gudanar da su akan kayan aikin bututu don tabbatar da ingancin samfurin.

Hydrotest donKayayyakin Bututu

- Gwajin Hydrostatic Ba'a buƙata don kayan aikin bututu sai dai idan mai siye ya buƙata ta musamman

- Ƙididdiga na lamba cewa kayan aiki za su iya jurewa ƙarƙashin matsin lamba da ake buƙata ta hanyar amfani da Lambobin Bututu.

- Yawancin masu siye sun ba da umarni, cewa a yi amfani da harsashin bututun ruwa da aka gwada don kera kayan aiki.

Gwajin Hujja

Gwajin Tabbacin Gwaji

Don cancantar ƙirar ƙirar bututun, masana'anta sun yi gwaji daban-daban gami da gwajin fashe don tabbatar da cewa ƙira zai cika duk ƙa'idodi & buƙatun lamba. A cikin wannan gwajin, ana welded bututu & kayan aiki ana shirya spool mai dummi. Ana matsar da wannan bututun bututu don tantance ma'aunin gwajin fashe da aka ƙididdige. Idan kayan aikin sun yi tsayin daka da gwajin, duk samfuran da aka kera na gaba ta amfani da wannan ƙirar za su yi la'akari da aminci don amfani.

Ƙarshen haɗin gwiwa na ƙwallon ƙafa ba a keɓance su daga gwajin hujja saboda ana amfani da su tare da haɗin flange da ƙira idan aka yi la'akari da ƙimar zafin jiki mai dacewa.

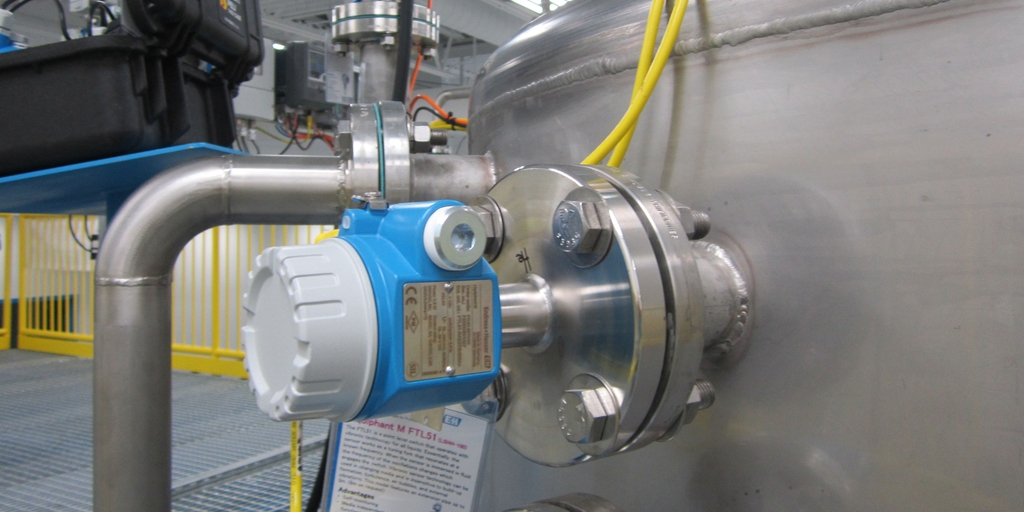

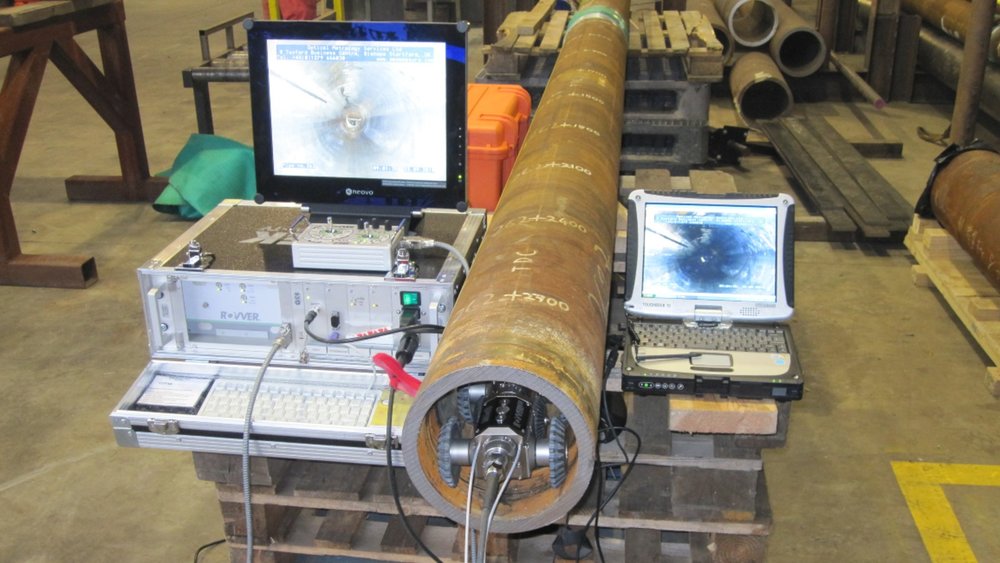

Gwajin mara lalacewa

Dangane da nau'in kayan aikin kowane ɗayan waɗannan gwaje-gwajen marasa lalacewa ana yin su akan kayan aikin da aka gama don tabbatar da ingancin samfur.

- Ultrasonic

- Radiography (Don Weld kawai)

- Gwajin barbashi na Magnetic

- Gwajin shigar ruwa

- Da kuma Gano Material Mai Kyau

Gwajin lalata

Ana yin gwaje-gwaje masu lalata don duba ƙarfin jiki da waldar samfurin.

- Gwajin tabbatarwa kuma ana kiranta da gwajin nau'in ko fashewa.

- Gwajin tensile

- Gwajin tasiri / Gwajin V-Notch Charpy

- Gwajin taurin

Gwajin lalata

Gwajin Karfe

Ana yin gwajin ƙarfe a jikin kayan aiki da walda don tabbatar da daidaitattun buƙatun

- Micro Analysis ko Chemical Analysis na

- Albarkatun kasa

- Samfura

- Weld

- Macro Analysis

- Weld

Gwajin Karfe

Gwaje-gwaje na Musamman

- Ana yin gwaje-gwaje na musamman akan kayan aiki don tabbatar da ikon jurewa a cikin mahalli masu lalata. Waɗannan gwaje-gwajen sune

- IGC- Gwajin Lalacewar Intergranular (SS)

- Ferrite (SS)

- HIC - Haɗaɗɗen hydrogen

- Kuma SSC- Sulfide Stress Lalacewar Cracking

- Girman hatsi (AS & SS) na kayan ana duba don tabbatar da ƙananan tsarin

Gwaje-gwaje na Musamman

GANIN KYAUTA

Ana gudanar da Duban gani akan kayan aiki don bincika kowane lahani na saman. Duka jikin kayan aiki da weld ana duba su ga duk wani lahani na bayyane kamar haƙora, alamomin mutuwa, porosity, yanke da sauransu. Yarda kamar yadda ya dace.

Duban gani

Alamar Daidaita Bututu

Za a yi alama mai zuwa akan Fittings

- Tambarin masana'anta

- ASTM material code

- Matsayin Material

- Girman, don girman Tee na reshe & bututun gudu da don rage girman ƙarshen duka biyun

- Kauri (Jadawalin A'a) na ƙarshen biyu idan an haɗa su da bututu mai kauri daban-daban

- Zafi A'a

- Yarda - don daidaitattun kayan aiki -WP, don kayan aiki na musamman S58, S8, SPLD da sauransu.

Alamar Kayan Aikin Bututu

Lokacin aikawa: Juni-14-2022