Pipe Fitting Inspection & Testing

During the manufacturing various Inspection & Testing are carried out on pipe fitting to ensure quality of the product.

Hydrotest for Pipe Fittings

- Hydrostatic Test Not required for pipe fittings unless specifically requested by purchaser

- Code mandate that fittings shall be able to withstand under pressure required by applicable Piping Code.

- Most purchasers mandate, that a hydro tested pipe shell be used to manufacture fittings.

Proof Test

Brust Test Proof Test

To qualified the design of the pipe fitting, manufacturer performed a various test including burst test to ensure that design will meet the all the standard & code requirements. In this test, a pipe & fittings are welded and a dummy pipe spool is prepared. This pipe spool is then pressurized to pre-define calculated burst test pressure. If the fittings withstand the test, all the future product manufactured using that design will consider safe to use.

Lap joint stub ends are exempt from the proof test because they are used with flange assembly and design considering applicable pressure- temperature ratings.

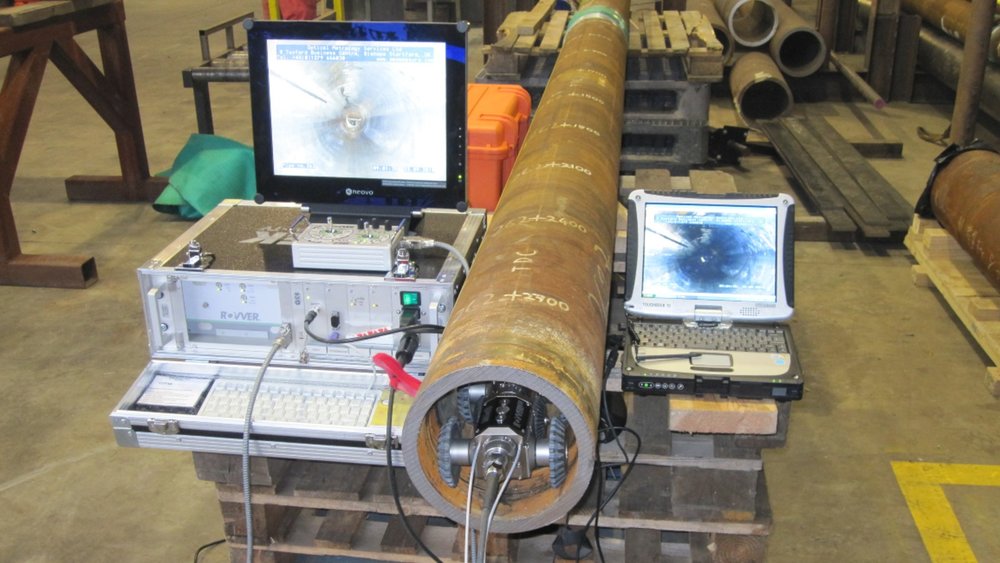

Non-Destructive testing

Based on the type of fittings any of the following Non-Destructive testings are performed on finished fittings to ensure the soundness of product.

- Ultrasonic

- Radiography (Only for Weld)

- Magnetic particle test

- Liquid penetrant test

- And Positive Material Identification

Destructive Testing

Destructive Testings are performed to check the strength of the body and weld of the product.

- The proof test is also known as type test or burst test.

- Tensile test

- Impact test / Charpy V-Notch Test

- Hardness test

Destructive Testing

Metallurgical Tests

Metallurgical Tests are performed on fittings body and weld to confirm standard requirements

- Micro Analysis or Chemical Analysis of

- Raw material

- Product

- Weld

- Macro Analysis

- Weld

Metallurgical Tests

Special Tests

- Special tests are carried out on fittings to confirm its ability to withstand in corrosive environments. These tests are

- IGC- Intergranular Corrosion Test(SS)

- Ferrite (SS)

- HIC- Hydrogen-induced Cracking

- And SSC- Sulfide Stress Corrosion Cracking

- Grain size (AS & SS) of material are checked to confirm microstructure

Special Tests

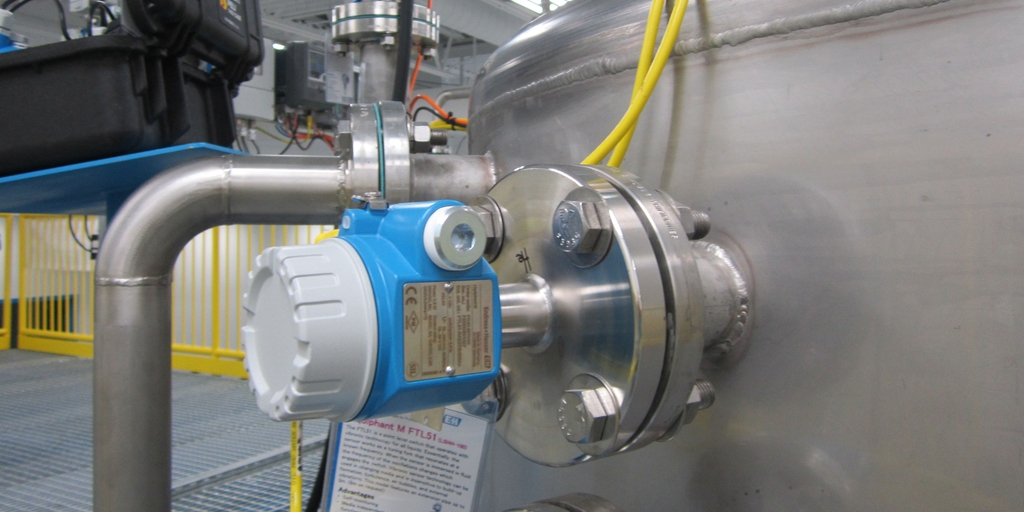

VISUAL INSPECTION

Visual Inspection is conducted on fittings to check any surface imperfections. Both fittings body and weld are checked for any visible surface imperfections such as dents, die marks, porosity, undercuts etc. Acceptance as per applicable standard.

Visual Inspection

Pipe Fitting Marking

Following shall be marked on Fittings

- Manufacturer logo

- ASTM material code

- Material Grade

- Size, for tee size of branch & run pipe and for reducer size of both end

- Thickness (Schedule No) for both the ends if they are connected to different thickness pipe

- Heat No

- Compliance – for standard fittings –WP, for Special fittings S58, S8, SPLD etc.

Pipe Fittings Marking

Post time: Jun-14-2022