Titan Flange

Typen vun Titan Flange

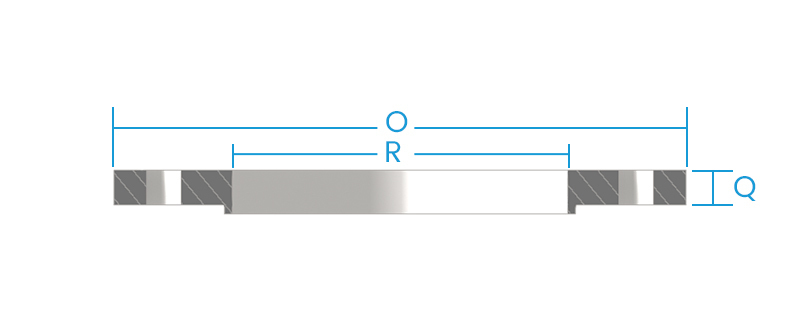

Blind Flanges

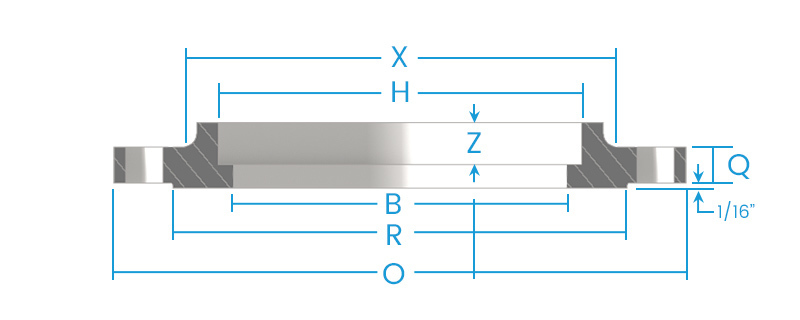

| NOMINAL | AUSSEN | DECKTE | DIA.VUN | NUMMER VUN | DIA.VUN | DIA.VUN |

| O | Q** | R | ||||

| 1/2 | 3-1/2 | 7/16 | 1-3/8 | 4 | 1/2 | 2-3/8 |

| 3/4 | 3-7/8 | 1/2 | 1-11/16 | 4 | 1/2 | 2-3/4 |

| 1 | 4-1/4 | 9/16 | 2 | 4 | 1/2 | 3-1/8 |

| 1-1/4 | 4-5/8 | 5/8 | 2-1/2 | 4 | 1/2 | 3-1/2 |

| 1-1/2 | 5 | 11/16 | 2-7/8 | 4 | 1/2 | 3-7/8 |

| 2 | 6 | 3/4 | 3-5/8 | 4 | 5/8 | 4-3/4 |

| 2-1/2 | 7 | 7/8 | 4-1/8 | 4 | 5/8 | 5-1/2 |

| 3 | 7-1/2 | 15/16 | 5 | 4 | 5/8 | 6 |

| 3-1/2 | 8-1/2 | 15/16 | 5-1/2 | 8 | 5/8 | 7 |

| 4 | 9 | 15/16 | 6-3/16 | 8 | 5/8 | 7-1/2 |

| 5 | 10 | 15/16 | 7-5/16 | 8 | 3/4 | 8-1/2 |

| 6 | 11 | 1 | 8-1/2 | 8 | 3/4 | 9-1/2 |

| 8 | 13-1/2 | 1-1/8 | 10-5/8 | 8 | 3/4 | 11-3/4 |

| 10 | 16 | 1-3/16 | 12-3/4 | 12 | 7/8 | 14-1/4 |

| 12 | 19 | 1-1/4 | 15 | 12 | 7/8 | 17 |

| 14 | 21 | 1-3/8 | 16-1/4 | 12 | 1 | 18-3/4 |

| 16 | 23-1/2 | 1-7/16 | 18-1/2 | 16 | 1 | 21-1/4 |

| 18 | 25 | 1-9/16 | 21 | 16 | 1-1/8 | 22-3/4 |

| 20 | 27-1/2 | 1-11/16 | 23 | 20 | 1-1/8 | 25 |

| 24 | 32 | 1-7/8 | 27-1/4 | 20 | 1-1/4 | 29-1/2 |

*Beim Bestellung spezifizéiert d'nominal Päifgréisst oder d'"O" Dimensioun an Zoll, wat beweist wat benotzt gëtt, Drockbewäertung vum Flange an Deelnummer.

** Den 1/16 ″ opgehuewe Gesiicht ass an der Dicke "Q" abegraff.

+ Bolt Lächer sinn 1/8 ″ méi grouss wéi Bolzen Duerchmiesser.

• Dës Längt enthalen Dicke vun zwee Nëss, awer net Héicht vun der Kroun.

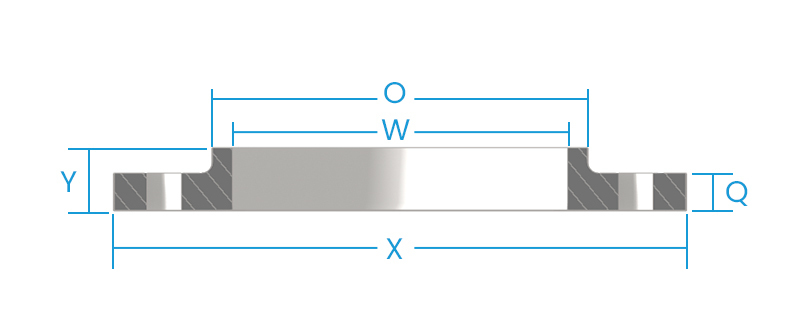

Slip-on Flanges

| NOMINAL | AUSSEN | DECKTE | DIA.VUN | DIA.VUN HUB | Längt | DIA.VUN BORE | NUMMER VUN | DIA.VUN | DIA.VUN |

| O | Q** | R | X | Y** | W | ||||

| 1/2 | 3-1/2 | 7/16 | 1-3/8 | 1-3/16 | 5/8 | .88 | 4 | 1/2 | 2-3/8 |

| 3/4 | 3-7/8 | 1/2 | 1-11/16 | 1-1/2 | 5/8 | 1.09 | 4 | 1/2 | 2-3/4 |

| 1 | 4-1/4 | 9/16 | 2 | 1-15/16 | 11/16 | 1.36 | 4 | 1/2 | 3-1/8 |

| 1-1/4 | 4-5/8 | 5/8 | 2-1/2 | 2-5/16 | 13/16 | 1,70 | 4 | 1/2 | 3-1/2 |

| 1-1/2 | 5 | 11/16 | 2-7/8 | 2-9/16 | 7/8 | 1,95 | 4 | 1/2 | 3-7/8 |

| 2 | 6 | 3/4 | 3-5/8 | 3-1/16 | 1 | 2.44 | 4 | 5/8 | 4-3/4 |

| 2-1/2 | 7 | 7/8 | 4-1/8 | 3-9/16 | 1-1/8 | 2,94 | 4 | 5/8 | 5-1/2 |

| 3 | 7-1/2 | 15/16 | 5 | 4-1/4 | 1-3/16 | 3,57 | 4 | 5/8 | 6 |

| 3-1/2 | 8-1/2 | 15/16 | 5-1/2 | 4-13/16 | 1-1/4 | 4.07 | 8 | 5/8 | 7 |

| 4 | 9 | 15/16 | 6-3/16 | 5-5/16 | 1-5/16 | 4,57 | 8 | 5/8 | 7-1/2 |

| 5 | 10 | 15/16 | 7-5/16 | 6-7/16 | 1-7/16 | 5,66 | 8 | 3/4 | 8-1/2 |

| 6 | 11 | 1 | 8-1/2 | 7-9/16 | 1-9/16 | 6,72 | 8 | 3/4 | 9-1/2 |

| 8 | 13-1/2 | 1-1/8 | 10-5/8 | 9-11/16 | 1-3/4 | 8,72 | 8 | 3/4 | 11-3/4 |

| 10 | 16 | 1-3/16 | 12-3/4 | 12 | 1-15/16 | 10.88 | 12 | 7/8 | 14-1/4 |

| 12 | 19 | 1-1/4 | 15 | 14-3/8 | 2-3/16 | 12.88 | 12 | 7/8 | 17 |

| 14 | 21 | 1-3/8 | 16-1/4 | 15-3/4 | 2-1/4 | 14.14 | 12 | 1 | 18-3/4 |

| 16 | 23-1/2 | 1-7/16 | 18-1/2 | 18 | 2-1/2 | 16.16 | 16 | 1 | 21-1/4 |

| 18 | 25 | 1-9/16 | 21 | 19-7/8 | 2-11/16 | 18.18 | 16 | 1-1/8 | 22-3/4 |

| 20 | 27-1/2 | 1-11/16 | 23 | 22 | 2-7/8 | 20.20 | 20 | 1-1/8 | 25 |

| 24 | 32 | 1-7/8 | 27-1/4 | 26-1/8 | 3-1/4 | 24.25 | 20 | 1-1/4 | 29-1/2 |

** Den 1/16 ″ opgehuewe Gesiicht ass an der Dicke "Q" a Längt "Y" abegraff.

+ Bolt Lächer sinn 1/8 ″ méi grouss wéi Bolzen Duerchmiesser.

• Dës Längt enthalen Dicke vun zwee Nëss, awer net Héicht vun der Kroun.

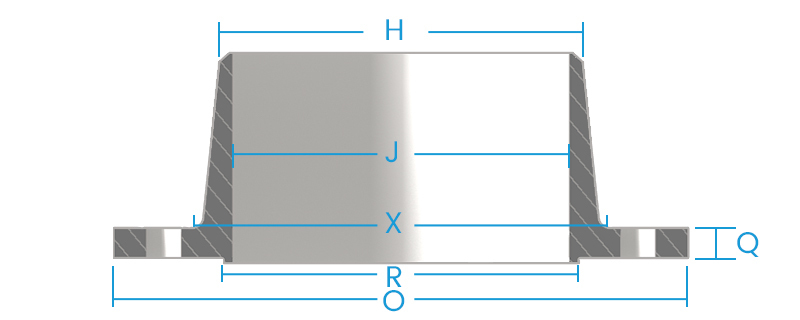

Weld HalsFlange

| NOMINAL | AUSSEN | DECKTE | DIA.VUN | DIA.VUN | MIN.DIA.VUN HUB AN PUNT VUN Schweess | Längt THRU HUB | DIA.VUN BORE | NUMMER VUN | DIA.VUN | DIA.VUN |

| O | Q** | R | X | H | Y** | J ♢ | ||||

| 1/2 | 3-1/2 | 7/16 | 1-3/8 | 1-3/16 | 0,84 | 1-7/8 | 0,62 | 4 | 1/2 | 2-3/8 |

| 3/4 | 3-7/8 | 1/2 | 1-11/16 | 1-1/2 | 1.05 | 2-1/16 | 0,82 | 4 | 1/2 | 2-3/4 |

| 1 | 4-1/4 | 9/16 | 2 | 1-15/16 | 1.32 | 2-3/16 | 1.05 | 4 | 1/2 | 3-1/8 |

| 1-1/4 | 4-5/8 | 5/8 | 2-1/2 | 2-5/16 | 1.66 | 2-1/4 | 1.38 | 4 | 1/2 | 3-1/2 |

| 1-1/2 | 5 | 11/16 | 2-7/8 | 2-9/16 | 1,90 | 2-7/16 | 1.61 | 4 | 1/2 | 3-7/8 |

| 2 | 6 | 3/4 | 3-5/8 | 3-1/16 | 2.38 | 2-1/2 | 2.07 | 4 | 5/8 | 4-3/4 |

| 2-1/2 | 7 | 7/8 | 4-1/8 | 3-9/16 | 2.88 | 2-3/4 | 2.47 | 4 | 5/8 | 5-1/2 |

| 3 | 7-1/2 | 15/16 | 5 | 4-1/4 | 3,50 | 2-3/4 | 3.07 | 4 | 5/8 | 6 |

| 3-1/2 | 8-1/2 | 15/16 | 5-1/2 | 4-13/16 | 4.00 | 2-13/16 | 3,55 | 8 | 5/8 | 7 |

| 4 | 9 | 15/16 | 6-3/16 | 5-5/16 | 4,50 | 3 | 4.03 | 8 | 5/8 | 7-1/2 |

| 5 | 10 | 15/16 | 7-5/16 | 6-7/16 | 5,56 | 3-1/2 | 5.05 | 8 | 3/4 | 8-1/2 |

| 6 | 11 | 1 | 8-1/2 | 7-9/16 | 6,63 | 3-1/2 | 6.07 | 8 | 3/4 | 9-1/2 |

| 8 | 13-1/2 | 1-1/8 | 10-5/8 | 9-11/16 | 8,63 | 4 | 7,98 | 8 | 3/4 | 11-3/4 |

| 10 | 16 | 1-3/16 | 12-3/4 | 12 | 10.75 | 4 | 10.02 | 12 | 7/8 | 14-1/4 |

| 12 | 19 | 1-1/4 | 15 | 14-3/8 | 12.75 | 4-1/2 | 12.00 | 12 | 7/8 | 17 |

| 14 | 21 | 1-3/8 | 16-1/4 | 15-3/4 | 14.00 Auer | 5 | 13.25 | 12 | 1 | 18-3/4 |

| 16 | 23-1/2 | 1-7/16 | 18-1/2 | 18 | 16.00 Auer | 5 | 15.25 | 16 | 1 | 21-1/4 |

| 18 | 25 | 1-9/16 | 21 | 19-7/8 | 18.00 Auer | 5-1/2 | 17.25 | 16 | 1-1/8 | 22-3/4 |

| 20 | 27-1/2 | 1-11/16 | 23 | 22 | 20.00 Auer | 5-11/16 | 19.25 | 20 | 1-1/8 | 25 |

| 24 | 32 | 1-7/8 | 27-1/4 | 26-1/8 | 24.00 Auer | 6 | 23.25 | 20 | 1-1/4 | 29-1/2 |

** Den 1/16 ″ opgehuewe Gesiicht ass an der Dicke "Q" a Längt "Y" abegraff.

+ Bolt Lächer sinn 1/8 ″ méi grouss wéi Bolzen Duerchmiesser.

• Dës Längt enthalen Dicke vun zwee Nëss, awer net Héicht vun der Kroun.

♢ Wann net anescht bestallt, sinn Flanges zu dësen Dimensiounen langweilen déi der ID vun Standard Gewiicht Päif entspriechen wéi am American Standard B36.10 opgezielt.

Socket WeldFlange

| NOMINAL | AUSSEN | DECKTE | DIA.VUN | DIA.VUN HUB | Längt | DIA.VUN | DIA.VUN | Déift VUN |

| O | Q** | R | X | Y** | B | A | Z | |

| 1/4 | 3-1/2 | 7/16 | 1-3/8 | 1-3/16 | 5/8 | 0,364 | 0,580 | 3/8 |

| 3/8 | 3-1/2 | 7/16 | 1-3/8 | 1-3/16 | 5/8 | 0,493 | 0,715 | 3/8 |

| 1/2 | 3-1/2 | 7/16 | 1-3/8 | 1-3/16 | 5/8 | 0,622 | 0,88 | 3/8 |

| 3/4 | 3-7/8 | 1/2 | 1-11/16 | 1-1/2 | 5/8 | 0,824 | 1.09 | 7/16 |

| 1 | 4-1/4 | 9/16 | 2 | 1-15/16 | 1-1/16 | 1.049 | 1.36 | 1/2 |

| 1-1/4 | 4-5/8 | 5/8 | 2-1/2 | 2-5/16 | 1-3/16 | 1.380 | 1,70 | 9/16 |

| 1-1/2 | 5 | 11/16 | 2-7/8 | 2-9/16 | 7/8 | 1.610 | 1,95 | 5/8 |

| 2 | 6 | 3/4 | 3-5/8 | 3-1/16 | 1 | 2.067 | 2.44 | 11/16 |

| 2-1/2 | 7 | 7/8 | 4-1/8 | 3-9/16 | 1-1/8 | 2.469 | 2,94 | 3/4 |

| 3 | 7-1/2 | 15/16 | 5 | 4-1/4 | 1-3/16 | 3.068 | 3,57 | 13/16 |

| 3-1/2 | 8-1/2 | 15/16 | 5-1/2 | 4-13/16 | 1-1/4 | 3.548 | 4.07 | 7/8 |

| 4 | 9 | 15/16 | 6-3/16 | 5-5/16 | 1-5/16 | 4,026 | 4,56 | 15/16 |

| 5 | 10 | 15/16 | 7-5/16 | 6-7/16 | 1-7/16 | 5.047 | 5,66 | 15/16 |

| 6 | 11 | 1 | 8-1/2 | 7-9/16 | 1-9/16 | 6.065 | 6,72 | 1-1/16 |

| 8 | 13-1/2 | 1-1/8 | 10-5/8 | 9-11/16 | 1-3/4 | 7.981 | 8,72 | 1-1/4 |

| 10 | 16 | 1-3/16 | 12-3/4 | 12 | 1-15/16 | 10.020 | 10.88 | 1-5/16 |

| 12 | 19 | 1-1/4 | 15 | 14-3/8 | 2-3/16 | 12.000 | 12.88 | 1-9/16 |

| 14 | 21 | 1-3/8 | 16-1/4 | 15-3/4 | 2-1/4 | 13.250 | 14.19 | 1-5/8 |

| 16 | 23-1/2 | 1-7/16 | 18-1/2 | 18 | 2-1/2 | 15.250 | 16.19 | 1-3/4 |

| 18 | 25 | 1-9/16 | 21 | 19-7/8 | 2-11/16 | 17.250 | 18.19 | 1-15/16 |

| 20 | 27-1/2 | 1-11/16 | 23 | 22 | 2-7/8 | 19.250 | 20.19 | 2-1/8 |

| 24 | 32 | 1-7/8 | 27-1/4 | 26-1/8 | 3-1/4 | 23.250 | 24.19 | 2-1/2 |

* Gréissten 1/2 ″ bis 3 ″ sinn an ASA B16/5-1953 abegraff.Dimensiounen fir all aner Gréissten ausser fir d'Buer Dimensioun sinn déi selwecht wéi ASA Slip-on flanges.

** Den 1/16 ″ opgehuewe Gesiicht ass an der Dicke "Q" a Längt "Y" abegraff.Flanges sinn déi selwecht wéi ASA 150-lb gebuert.flanges.

Fir aner Titan Flange Typen a Gréissten, kontaktéiert eis w.e.g

| ASME/ANSI B 16.5 | Welding Neck Flange, Rutsch op Flange, Blind Flange, High Hub Blind Flange, Socket Weld Flange, Lap Joint Flange, Threaded Flange, Ring Type Joint Flange |

| Drock KLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| ASME/ANSI B 16.47 | Schweißhalsflänz, Blindflänz [Serie A & B] |

| Drock KLASS | 75, 150, 300, 400, 600, 900 |

| ASME/ANSI B 16.36 | Schweess Hals Flange, Rutsch op Flange, Threaded Flange |

| Drock KLASS | 300, 400, 600, 900, 1500, 2500 |

| BS 4504 SEC 3.1 | Schweißhalsflänz, Hubbed Slip on Flange, Hubbed Threaded Flange, Lapped Pipe End Flange, Plate Flange, Lose Plate Flange, Loose Plate With Weld Neck Flange, Blank Flange |

| Drock KLASS | PN 2,5 BIS PN 40 |

| BS 4504[PART 1] | Schweess Hals Flange, Hubbed Slip-On Hubbed Threaded, Plack Flange, Lose Plack Mat Weld On Plack Collar, Blank Flange |

| Drock KLASS | PN 2,5 BIS PN 400 |

| BS 1560 BOSS | Welding Neck Flange, Socket Welding Flange, Slip-On Flange, Blind Flange, Screwed Boss Flange, Lapped Flange |

| Drock KLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| BS 10 | Welding Neck Flange, Plate Slip-On Flange, Screwed Boss Flange, Slip-On Boss Flange, Blind Flange |

| TABEL | D, E, F, H |

| DIN FLANGES | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634. |

| Drock KLASS | PN 6 BIS PN 100 |

Chemesch Zesummesetzung

| Grad | Chemesch Zesummesetzung, Gewiicht Prozent (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Aner Elementer Max.jeweils | Aner Elementer Max.am Ganzen | |

| Gr 1 | 0,08 | 0.18 | 0,03 | 0,015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr 2 | 0,08 | 0,25 | 0,03 | 0,015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| gr4 | 0,08 | 0,25 | 0,03 | 0,015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| gr5 | 0,08 | 0.20 | 0,05 | 0,015 | 0,40 | 5,5-6,75 | 3.5-4.5 | - | - | - | - | 0.1 | 0.4 |

| gr7 | 0,08 | 0,25 | 0,03 | 0,015 | 0.30 | - | - | 0.12-0.25 | - | 0.12-0.25 | - | 0.1 | 0.4 |

| gr9 | 0,08 | 0.15 | 0,03 | 0,015 | 0,25 | 2,5-3,5 | 2.0-3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr 11 | 0,08 | 0.18 | 0,03 | 0.15 | 0.2 | - | - | 0.12-0.25 | - | - | - | 0.1 | 0.4 |

| Gr 12 | 0,08 | 0,25 | 0,03 | 0.15 | 0.3 | - | - | - | - | 0,6-0,9 | 0.2-0.4 | 0.1 | 0.4 |

| Gr 16 | 0,08 | 0,25 | 0,03 | 0.15 | 0.3 | - | - | 0.04-0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0,08 | 0.13 | 0,03 | 0,125 | 0,25 | 5.5-6.5 | 3.5-4.5 | - | - | - | - | 0.1 | 0.1 |