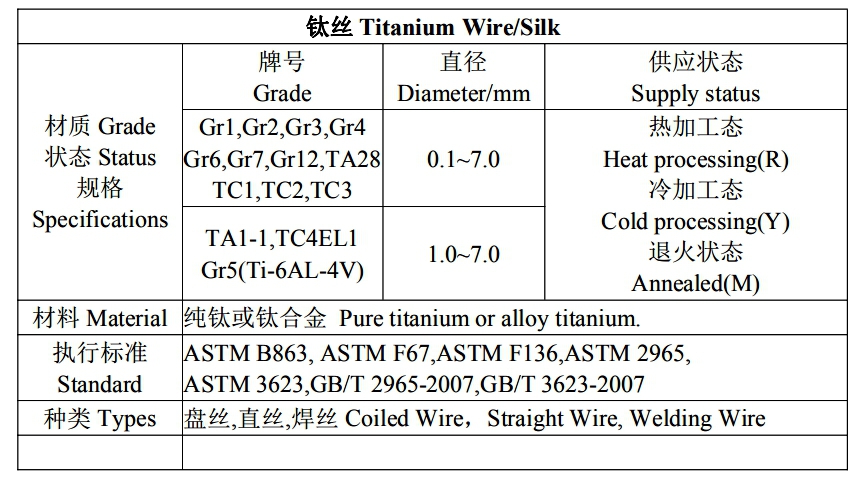

Titanium Wire / Silk

We could provide tantalum wire of vacuum electron beam melting and powder metallurgy technology, General purpose of tantalum wire was produced by vacuum electron beam melting technology,it has a relatively high purity. Capacitor grade tantalum wire usually was produced by powder metallurgy technology, it contains more special metal elements. Tantalum wire was produced on the basis of tantalum bar. first of all, rolling out the appropriate size of tantalum bar, cleaning the tantalum bar, to remove surface magazine and oil pollution, trimming the tantalum bar and clean again, then through stretching and annealing for many times, eventually get the specifications of customer requirements, through cleaning, straightening, winding, we can get the straight wire or coil. Giant Metal unique method of rolling, stretching process, compression ratio control, annealing temperature and annealing time control could guarantee tantalum wire have excellent mechanical properties, make the surface smooth, clean, no oil, there is no cracks and burrs, no mess around, and observed under 25 times magnification, it have not continuous dents and scratches, have good metallurgical structure, so as to ensure the quality of tantalum wire are better than other companies in the same industry.

In addition to provide pure tantalum wire, our company also provide tantalum alloy wire.

Material:

Tantalum Niobium wire (TaNb3, TaNb20, TaNb40)

Tantalum Tungsten wire (Ta2.5W, Ta10W)

Diameter: 0.1~4mm

Standard: ASTM B365

Shape: Straight, Coil

Status: Hard, Semi-hard, Mild

Application

Capacitor grade tantalum wire is mainly used for making tantalum electrolytic capacitor anode lead. tantalum wire is the key material to tantalum capacitor, tantalum capacitor is the best capacitor, about 65% of the world’s tantalum used in this field.

Be used to produce tantalum mesh.

Be used to suture to compensate muscle tissue, stitch nerves and tendons, production blood vessels stent, etc.

Be used to produce vacuum high temperature furnace heating components.

Used for vacuum electron emitting cathode source, ion sputtering and coating materials, etc.

|

Titanium Wire Diameters and Types |

||||

|

Diameter & Types |

||||

|

Diameter Range |

Types |

|||

| mm | inch | Coil | Spool | Straight |

| 0.05 to 0.78 | 0.002 to 0.031 | Y | Y | N |

| >0.78 to 3.25 | >0.031 to 0.128 | Y | Y | Y |

| > 3.25 to 6.00 | > 0.128 to 0.236 | Y | N | Y |

Diameter Tolerance: +/-0.05mm (+/-0.002”) or finer. Spools: 100mm – 300mm (3.9” – 12”). Straight Length: 300mm – 3000mm (12” – 118”)

|

Grade |

Specifications |

||

| AWS A5.16 | ASTM B863 | AMS | |

| Commercial Pure Titanium | ERTi-1,2,3,4 | ASTM B863 Gr1,2,3,4 | AMS 4951 |

| ASTM F67 Gr1,2,3,4 | AMS 4921 | ||

| Ti 6Al-4V | ERTi-5 | ASTM B863 Gr5 | AMS 4954 |

| Ti 6Al-4V Eli | ERTi-5 Eli | ASTM B863 Gr23 | AMS 4956 |

| ASTM F136 Eli | |||

| Ti 0.2 Pd | ERTi-7 | ASTM B863 Gr7 | – |

| Ti 3Al-2.5V | ERTi-9 | ASTM B863 Gr9 | – |

| Ti 0.3Mo-0.8Ni | ERTi-12 | ASTM B863 Gr12 | – |

Chemical composition

|

Composition (%) |

|||||||||||||

|

Grade |

Main elements |

Impurity content (≤) |

|||||||||||

|

Ta |

Nb |

Fe |

Si |

Ni |

W |

Mo |

Ti |

Nb |

O |

C |

H |

N |

|

|

Ta1 |

Bal |

— |

0.005 |

0.005 |

0.002 |

0.01 |

0.01 |

0.002 |

0.03 |

0.015 |

0.01 |

0.0015 |

0.005 |

|

Ta2 |

Bal |

— |

0.03 |

0.02 |

0.005 |

0.04 |

0.03 |

0.005 |

0.1 |

0.02 |

0.01 |

0.0015 |

0.005 |

|

TaNb3 |

Bal |

1.5~3.5 |

0.03 |

0.03 |

0.005 |

0.04 |

0.03 |

0.005 |

— |

0.02 |

0.01 |

0.005 |

0.01 |

|

TaNb20 |

Bal |

17.0~23.0 |

0.03 |

0.03 |

0.005 |

0.04 |

0.03 |

0.005 |

— |

0.02 |

0.01 |

0.005 |

0.01 |

|

TaNb40 |

Bal |

35.0~42.0 |

0.01 |

0.005 |

0.01 |

0.05 |

0.02 |

0.01 |

— |

0.02 |

0.01 |

0.015 |

0.01 |

|

Ta2.5W |

Bal |

— |

0.01 |

0.005 |

0.01 |

2.0 ~ 3.5 |

0.01 |

0.002 |

0.1 |

0.01 |

0.01 |

0.0015 |

0.01 |

|

Ta10W |

Bal |

— |

0.01 |

0.005 |

0.01 |

9.0 ~ 11.0 |

0.01 |

0.002 |

0.1 |

0.015 |

0.01 |

0.0015 |

0. |

Mechanical properties

|

Status |

Tensile strength (Mp) |

Elongation (%) |

|

Mild |

300~750 |

10~30 |

|

Semi-hard |

750~1250 |

1~6 |

|

Hard |

>1250 |

1~5 |

| TaNb3,TaNb20, the mechanical properties according to the factory measured. | ||

Tolerance (mm)

|

Diameter |

Tolerance |

|

0.1~0.2 |

< 0.005 |

|

0.2~0.5 |

< 0.007 |

|

0.5~0.7 |

< 0.010 |

|

0.7~1.5 |

< 0.015 |

|

1.5~2.0 |

< 0.020 |

|

2.0~3.0 |

< 0.030 |

|

3.0~4.0 |

< 0.040 |

Antioxidant brittleness

|

Grade |

Diameter (mm) |

Antioxidant brittleness Number of bending (≥) |

|

Ta1 |

0.10~0.40 |

3 |

|

>0.40 |

4 |

|

|

Ta2 |

0.10~0.40 |

4 |

|

>0.40 |

6 |

Coil wire: After the wind and parcel with pearl cotton(expandable polyethylene), then packed in wooden cases.

Straight wire: Pack the tantalum wire in plastic bags and put in plastic straight barrel, then packed in wooden cases.