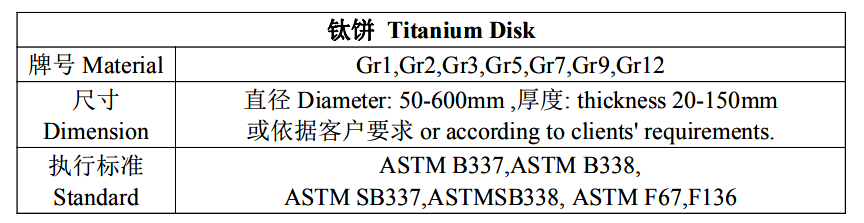

Titanium Disc / Target

| Name | Size(MM) | Grade | Specification |

| Titanium Disc | φ50-1000 Height:35-110 |

TA1,TA2, TA3,TA4, TC4, TC11, TC15etc |

GB/T,GJB, ASTM,A |

| Product | Size(mm) | Grade Nos | Specification | |

| Diameter | Section Height | |||

| Titanium & Titanium Alloy Discs | Φ(150~300) | 20~600 | TA1,TA2,TA3, TA4,TA9,TA10, TA15,TC4 |

GB/T,ASTM, ASME,AMS, ISO,JIS,MIL |

| Φ(300~500) | 20~600 | |||

| Φ(500~1100) | 35~600 | |||

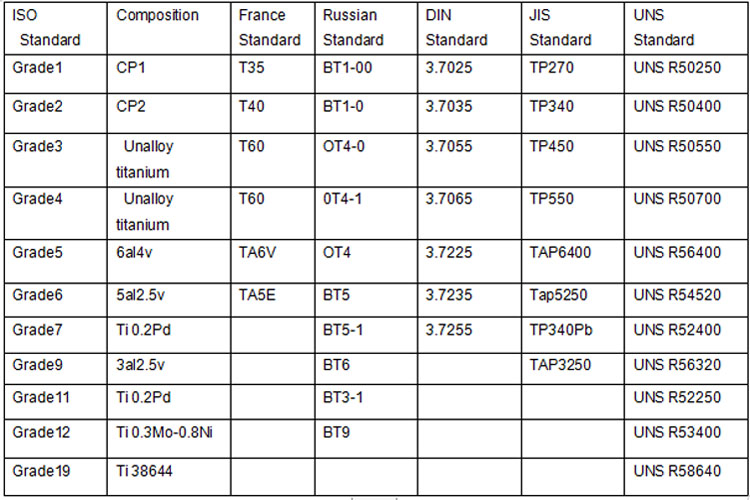

UNS No.

|

UNS No. |

UNS No. |

||||

|

Gr1 |

UNS R50250 |

CP-Ti |

Gr11 |

UNS R52250 |

Ti-0.15Pd |

|

Gr2 |

UNS R50400 |

CP-Ti |

Gr12 |

UNS R53400 |

Ti-0.3Mo-0.8Ni |

|

Gr4 |

UNS R50700 |

CP-Ti |

Gr16 |

UNS R52402 |

Ti-0.05Pd |

|

Gr7 |

UNS R52400 |

Ti-0.20Pd |

Gr23 |

UNS R56407 |

Ti-6Al-4V ELI |

|

Gr9 |

UNS R56320 |

Ti-3Al-2.5V |

|||

Chemical composition

|

Grade |

Chemical composition, weight percent (%) |

||||||||||||

|

C (≤) |

O (≤) |

N (≤) |

H (≤) |

Fe (≤) |

Al |

V |

Pd |

Ru |

Ni |

Mo |

Other Elements Max. each |

Other Elements Max. total |

|

|

Gr1 |

0.08 |

0.18 |

0.03 |

0.015 |

0.20 |

— |

— |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr2 |

0.08 |

0.25 |

0.03 |

0.015 |

0.30 |

— |

— |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr4 |

0.08 |

0.25 |

0.03 |

0.015 |

0.30 |

— |

— |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr5 |

0.08 |

0.20 |

0.05 |

0.015 |

0.40 |

5.5~6.75 |

3.5~4.5 |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr7 |

0.08 |

0.25 |

0.03 |

0.015 |

0.30 |

— |

— |

0.12~0.25 |

— |

0.12~0.25 |

— |

0.1 |

0.4 |

|

Gr9 |

0.08 |

0.15 |

0.03 |

0.015 |

0.25 |

2.5~3.5 |

2.0~3.0 |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr11 |

0.08 |

0.18 |

0.03 |

0.15 |

0.2 |

— |

— |

0.12~0.25 |

— |

— |

— |

0.1 |

0.4 |

|

Gr12 |

0.08 |

0.25 |

0.03 |

0.15 |

0.3 |

— |

— |

— |

— |

0.6~0.9 |

0.2~0.4 |

0.1 |

0.4 |

|

Gr16 |

0.08 |

0.25 |

0.03 |

0.15 |

0.3 |

— |

— |

0.04~0.08 |

— |

— |

— |

0.1 |

0.4 |

|

Gr23 |

0.08 |

0.13 |

0.03 |

0.125 |

0.25 |

5.5~6.5 |

3.5~4.5 |

— |

— |

— |

— |

0.1 |

0.1 |

Physical properties

|

Grade |

Physical properties |

|||||

|

Tensile strength Min |

Yield strength Min (0.2%, offset) |

Elongation in 4D Min (%) |

Reduction of Area Min (%) |

|||

|

ksi |

MPa |

ksi |

MPa |

|||

|

Gr1 |

35 |

240 |

20 |

138 |

24 |

30 |

|

Gr2 |

50 |

345 |

40 |

275 |

20 |

30 |

|

Gr4 |

80 |

550 |

70 |

483 |

15 |

25 |

|

Gr5 |

130 |

895 |

120 |

828 |

10 |

25 |

|

Gr7 |

50 |

345 |

40 |

275 |

20 |

30 |

|

Gr9 |

90 |

620 |

70 |

483 |

15 |

25 |

|

Gr11 |

35 |

240 |

20 |

138 |

24 |

30 |

|

Gr12 |

70 |

483 |

50 |

345 |

18 |

25 |

|

Gr16 |

50 |

345 |

40 |

275 |

20 |

30 |

|

Gr23 |

120 |

828 |

110 |

759 |

10 |

15 |

For the packing of small quantity products : Paper/Plastic and Carton

For the packing of large quantity products : Paper/foam inside,wooden pallet outside.