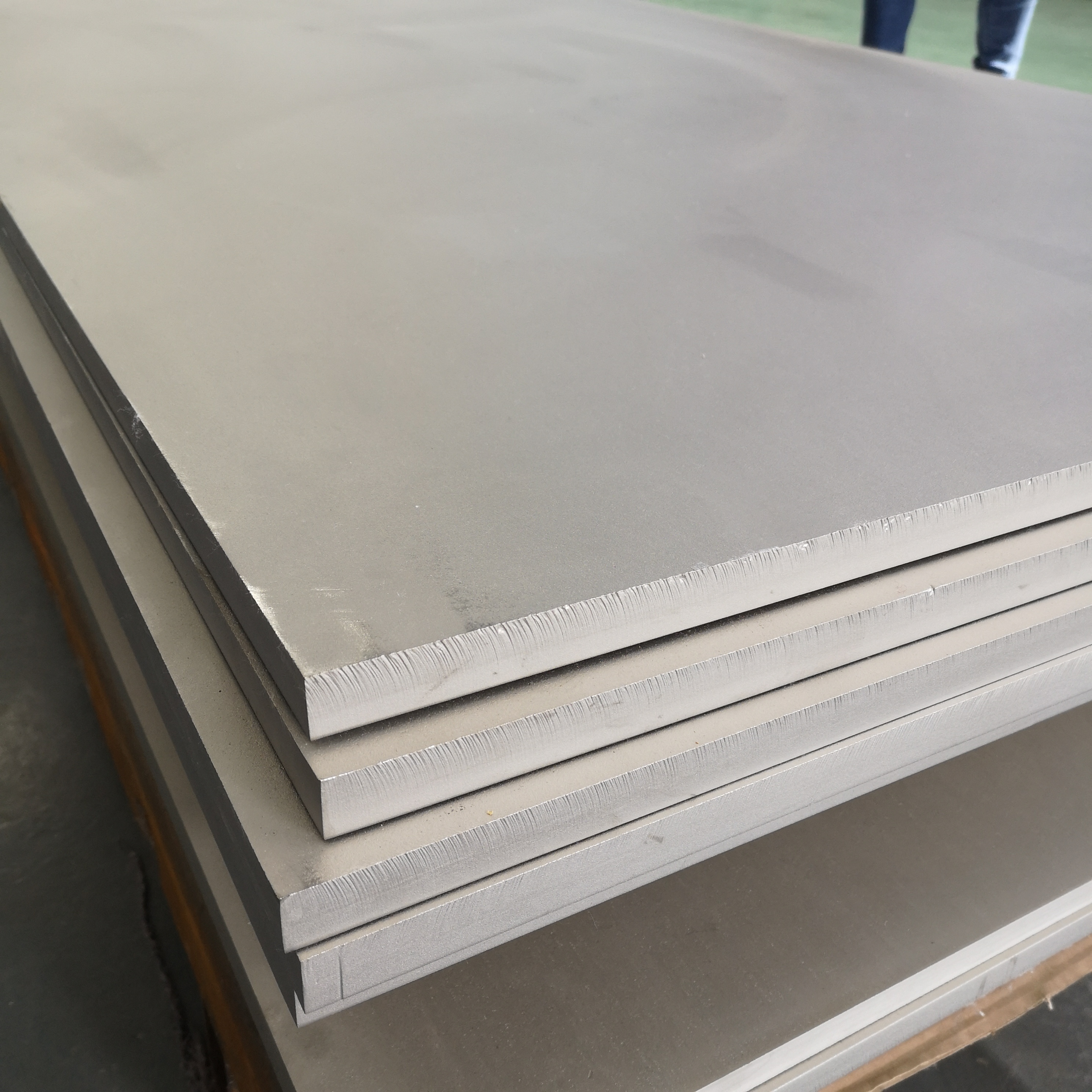

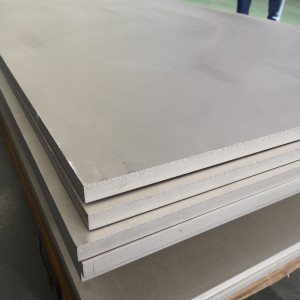

Titanium Sheet / Plate

Common Grades

Titanium Grade 1 is an unalloyed, low strength titanium product containing low oxygen with high form ability; this titanium grade is used in air frames, heat exchanges and desalination units.

Titanium Grade 2 is an unalloyed, medium strength titanium product. This titanium grade is used in air frames, aircraft engines and marine parts; good weld ability and corrosion resistance are its distinguishing characteristics.

Titanium Grade 3 is an unalloyed, high strength, titanium product providing excellent corrosion resistance and good weld ability. This titanium grade is primarily used in air frame and aircraft engine parts.

Titanium Grade 4 is the highest strength pure unalloyed titanium product. This titanium grade is used almost exclusively for air frame, aircraft engine parts, marine, surgical implants, hydraulic tubing. Good form ability and corrosion resistance are its hallmark.

Titanium Grade 5 (6AL-4V)is an alloyed titanium product containing 6% Aluminum and 4% Vanadium; is a medium strength product. This titanium grade is predominantly used in airframe and turbine engine parts; and for use in surgical implants. Technical Info Titanium 6AL – 4V ELI is an alloyed titanium product containing 6% Aluminum and 4% Vanadium, ELI (Extra Low Interstitial).

6AL–2Sn–4Zr–2Mo (6-2-4-2)is an alloyed titanium product containing 6% Aluminum, 2% Tin, 4% Zirconium, 2% Molybdenum.

6AL–6V–2Sn (6-6-2)is an alloyed titanium product containing 6% Aluminum, 6% Vanadium, 2% Tin.

5AL–2.5Sn & ELI (5-2.5)is an alloyed titanium product containing 5% Aluminum and 2.5% Tin. Also ELI (Extra Low Interstitial).

8AL–1V–1Mo (8-1-1)is an alloyed titanium product containing 8% Aluminum, 1% Molybdenum and 1% Vanadium.

15V–3Cr–4AL–3Sn (15-3-4-3)is an alloyed titanium product containing 15% Vanadium, 3% Chromium, 4% Aluminum, 3% Tin.

|

Grade |

Status |

Specification |

||

|

Gr1,Gr2,Gr4,Gr5,Gr7,Gr9,Gr11, Gr12,Gr16,Gr23 |

Hot Rolled(R) Cold Rolled(Y) Annealed(M) Solution treatment(ST) |

Thickness(mm) |

Width(mm) |

Length(mm) |

|

0.3~60 |

≥400 |

≤ 6000 |

||

|

Titanium Sheet |

|||

| Thickness | Grades | ||

| .016 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .020 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .025 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .032 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .040 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .050 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .063 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .071 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .080 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .090 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .100 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .125 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

Note: Additional sizes available, not all sizes shown are available from stock. Please contact us to check availability.

| AMS: AMS 2631, AMS 4901, AMS 4907, AMS 4911ASTM: ASTM B265 Gr 23, ASTM B265 Gr 5, ASTM B265 Gr2, ASTM B265 Gr4, ASTM F136, ASTM F67MIL-T: MIL-T-9046, MIL-T-9046 CP1EN: EN 10204.3, EN 1-204:2005 3.1

NACE: NACE MR0175 ASME: ASME SB265 |

| Grade | AMS/MIL Specs | ASTM Specs |

| Grade 1 | AMS-T-9046B CP4 AMS 4940 MIL-T-9046J CP4 |

ASTM B265 Gr1 Sheet/plate ASTM B337 Gr1 pipe ASTM B338 Gr1 tube ASTM B348 Gr1 bar ASTM F67 Gr1 Surgical Implant |

| Grade 2 | Grade 2 AMS-T-9046B CP3 AMS 4902 MIL-T-9046J CP3 AMS 4941 AMS 4942 AMS 4951 Welding wire |

ASTM B265 Gr2 Sheet/plate ASTM B337 Gr2 pipe ASTM B338 Gr2 tube ASTM B348 Gr2 bar ASTM F67 Gr2 Surgical Implant |

| Grade 3 | AMS-T-9046B CP2 AMS 4900 MIL-T-9046J CP2 |

ASTM B265 Gr3 Sheet/plate ASTM B337 Gr3 pipe ASTM B338 Gr3 tube ASTM B348 Gr3 bar ASTM F67 Gr3 Surgical Implant |

| Grade 4 | AMS-T-9046B CP1 AMS-T-9047A CP70 AMS 4901 AMS 4921 MIL-T-9046J CP1 MIL-T-9047G CP70 |

ASTM B265 Gr4 Sheet/plate ASTM B337 Gr4 pipe ASTM B338 Gr4 tube ASTM B348 Gr4 bar ASTM F67 Gr4 Surgical Implant |

| Grade 7 | ASTM B265 Gr7 Sheet/plate ASTM B337 Gr7 pipe ASTM B338 Gr7 tube ASTM B348 Gr7 bar |

| Grade | US Specs | ASTM Specs |

| Grade 5 6Al-4V | AMS 4907 ELI AMS 4911 AMS 4928 AMS 4930 ELI AMS 4931 ELI Duplex ann AMS 4963 AMS 4965 AMS 4967 AMS 4985 AMS 4991 AMS 6931 AMS 6932 MIL-T-9046J AB-1 MIL-T-9046J AB-2 (ELI) MIL-T-9046H Type 3 Comp C MIL-T-9046H Type 3 Comp D AMS-T-9046B AB-1 AMS-T-9046B AB-2 (ELI) MIL-T-9047G 6Al-4v MIL-T-9047G 6Al-4v (ELI) AMS-T-9047A 6Al-4v AMS-T-9047A 6Al-4v (ELI) |

ASTM B265 Gr5 Sheet/plate ASTM B348 Gr5 bar ASTM F136 Gr5 Implant Grade |

| Grade 9 3Al-2.5V | AMS 4943 AMS 4944 AMS 4945 AMS-T-9046B AB-5 AMS-T-9047A 3Al-2.5V MIL-T-9046J AB-5 MIL-T-9047 3Al-2.5V |

ASTM B265 Gr6 Sheet/plate ASTM B348 Gr6 bar |

| Grade 23 6Al-4V ELI | AMS 4907 AMS 4930 AMS 6932 AMS-T-9046 AB-2 6AL-4V (ELI) AMS-T-9047 AB-2 6AL-4V (ELI) MIL-T-9046 AB-2 6AL-4V (ELI) MIL-T-9047 6AL-4V (ELI) |

ASTM B265 Gr23 sheet/plate/strip ASTM B348 Gr23 bar/billet ASTM F136 Gr23 Implant Gra |

Chemical composition

|

Grade |

Chemical composition, weight percent (%) |

||||||||||||

|

C ≤ |

O ≤ |

N ≤ |

H ≤ |

Fe ≤ |

Al |

V |

Pd |

Ru |

Ni |

Mo |

Other Elements Max. each |

Other Elements Max. total |

|

|

Gr1 |

0.08 |

0.18 |

0.03 |

0.015 |

0.20 |

— |

— |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr2 |

0.08 |

0.25 |

0.03 |

0.015 |

0.30 |

— |

— |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr4 |

0.08 |

0.25 |

0.03 |

0.015 |

0.30 |

— |

— |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr5 |

0.08 |

0.20 |

0.05 |

0.015 |

0.40 |

5.5~6.75 |

3.5~4.5 |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr7 |

0.08 |

0.25 |

0.03 |

0.015 |

0.30 |

— |

— |

0.12~0.25 |

— |

0.12~0.25 |

— |

0.1 |

0.4 |

|

Gr9 |

0.08 |

0.15 |

0.03 |

0.015 |

0.25 |

2.5~3.5 |

2.0~3.0 |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr11 |

0.08 |

0.18 |

0.03 |

0.15 |

0.2 |

— |

— |

0.12~0.25 |

— |

— |

— |

0.1 |

0.4 |

|

Gr12 |

0.08 |

0.25 |

0.03 |

0.15 |

0.3 |

— |

— |

— |

— |

0.6~0.9 |

0.2~0.4 |

0.1 |

0.4 |

|

Gr16 |

0.08 |

0.25 |

0.03 |

0.15 |

0.3 |

— |

— |

0.04~0.08 |

— |

— |

— |

0.1 |

0.4 |

|

Gr23 |

0.08 |

0.13 |

0.03 |

0.125 |

0.25 |

5.5~6.5 |

3.5~4.5 |

— |

— |

— |

— |

0.1 |

0.1 |

Physical properties

|

Grade |

Physical properties |

||||||

|

Tensile strength Min |

Yield strength (0.2%, offset) |

Elongation in 50mm Min (%) |

|||||

|

ksi |

MPa |

Min |

Max |

||||

|

ksi |

MPa |

ksi |

MPa |

||||

|

Gr1 |

35 |

240 |

20 |

138 |

45 |

310 |

24 |

|

Gr2 |

50 |

345 |

40 |

275 |

65 |

450 |

20 |

|

Gr4 |

80 |

550 |

70 |

483 |

95 |

655 |

15 |

|

Gr5 |

130 |

895 |

120 |

828 |

— |

— |

10 |

|

Gr7 |

50 |

345 |

40 |

275 |

65 |

450 |

20 |

|

Gr9 |

90 |

620 |

70 |

483 |

— |

— |

15 |

|

Gr11 |

35 |

240 |

20 |

138 |

45 |

310 |

24 |

|

Gr12 |

70 |

483 |

50 |

345 |

— |

— |

18 |

|

Gr16 |

50 |

345 |

40 |

275 |

65 |

450 |

20 |

|

Gr23 |

120 |

828 |

110 |

759 |

— |

— |

10 |

Tolerance (mm)

|

Thickness |

Width tolerance |

||

|

400~1000 |

1000~2000 |

>2000 |

|

|

5.0~6.0 |

±0.35 |

±0.40 |

±0.60 |

|

6.0~8.0 |

±0.40 |

±0.60 |

±0.80 |

|

8.0~10.0 |

±0.50 |

±0.60 |

±0.80 |

|

10.0~15.0 |

±0.70 |

±0.80 |

±1.00 |

|

15.0~20.0 |

±0.70 |

±0.90 |

±1.10 |

|

20.0~30.0 |

±0.90 |

±1.00 |

±1.20 |

|

30.0~40.0 |

±1.10 |

±1.20 |

±1.50 |

|

40.0~50.0 |

±1.20 |

±1.50 |

±2.00 |

|

50.0~60.0 |

±1.60 |

±2.00 |

±2.50 |