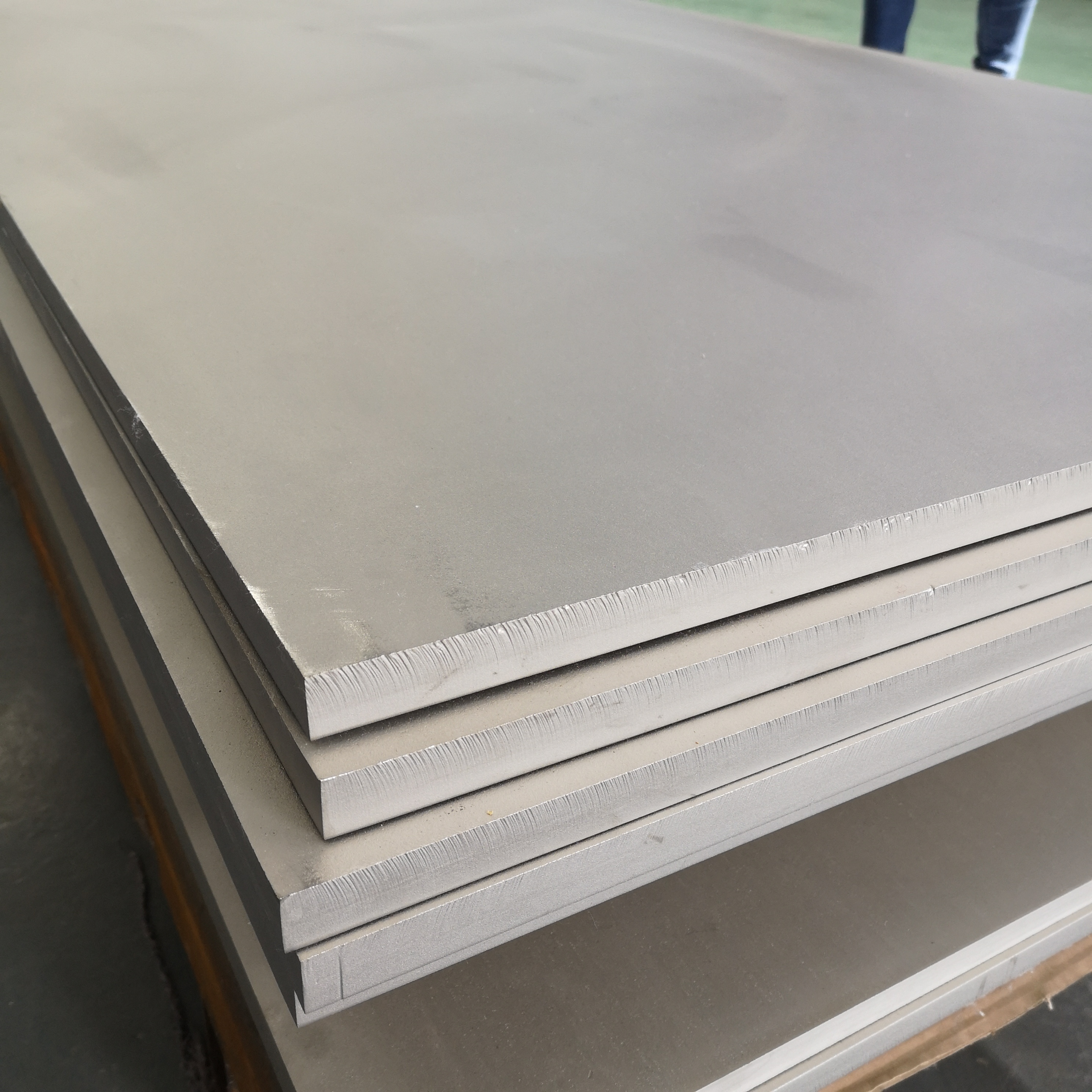

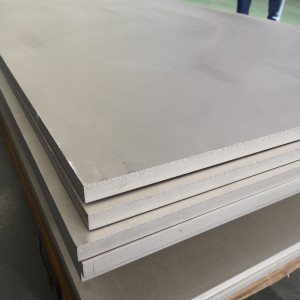

Mpempe akwụkwọ Titanium / efere

Ọkwa nkịtị

Titanium ọkwa 1bụ ngwaahịa titanium na-adịghị ike, nke nwere obere oxygen nwere ikike ụdị dị elu;A na-eji ọkwa titanium a na okpokolo agba ikuku, mgbanwe okpomọkụ na nkeji desalination.

Titanium ọkwa 2bụ ngwaahịa titanium na-enweghị ntụ, ọkara ike.A na-eji ọkwa titanium a na okpokolo agba ikuku, injin ụgbọ elu na akụkụ mmiri;ezi weld ike na corrosion iguzogide bụ ya iche iche àgwà.

Titanium ọkwa 3bụ unalloyed, elu ike, titanium ngwaahịa na-enye magburu onwe corrosion eguzogide na ezi weld ike.A na-eji ọkwa titanium a nke ọma na etiti ikuku na akụkụ injin ụgbọ elu.

Titanium ọkwa 4bụ ike kasị elu dị ọcha unalloyed titanium ngwaahịa.A na-eji ọkwa titanium a ihe fọrọ nke nta ka ọ bụrụ naanị maka etiti ikuku, akụkụ engine ụgbọ elu, mmiri mmiri, ntinye ịwa ahụ, tubing hydraulic.Ezi ikike ụdị na nguzogide corrosion bụ akara ya.

Titanium ọkwa 5 (6AL-4V)bụ ngwaahịa titanium alloyed nwere 6% Aluminom na 4% Vanadium;bụ ngwaahịa ike ọkara.A na-ejikarị ọkwa titanium a eme ihe na ikuku ikuku na akụkụ injin turbine;na maka ojiji na ịwa ahụ implants.Ozi nka nka Titanium 6AL-4V ELI bụ ngwaahịa titanium alloyed nwere 6% Aluminom na 4% Vanadium, ELI (Extra Low Interstitial).

6 AL-2Sn-4Zr-2Mo (6-2-4-2)bụ ngwaahịa titanium alloyed nwere 6% Aluminom, 2% Tin, 4% Zirconium, 2% Molybdenum.

6 AL-6V-2Sn (6-6-2)bụ ngwaahịa titanium alloyed nwere 6% Aluminom, 6% Vanadium, 2% Tin.

5AL-2.5Sn & ELI (5-2.5)bụ ngwaahịa titanium alloyed nwere 5% Aluminom na 2.5% Tin.Ọzọkwa ELI (Extra Low Interstitial).

8 AL-1V-1Mo (8-1-1)bụ ngwaahịa titanium alloyed nwere 8% Aluminom, 1% Molybdenum na 1% Vanadium.

15V-3Cr-4 AL-3Sn (15-3-4-3)bụ ngwaahịa titanium alloyed nwere 15% Vanadium, 3% Chromium, 4% Aluminom, 3% Tin.

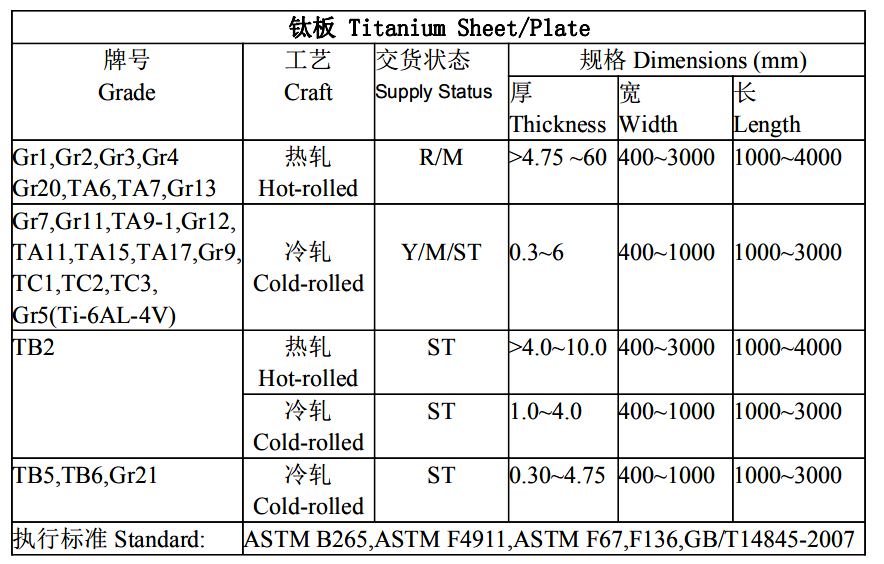

| Ọkwa | Ọnọdụ | Nkọwapụta | ||

| Gr1,Gr2,Gr4,Gr5,Gr7,Gr9,Gr11, Gr12,Gr16,Gr23 | Hot Rolled(R) Oyi Rolled(Y) Annealed(M) Ọgwụgwọ ọgwụgwọ (ST) | Ọkpụrụkpụ (mm) | Obosara (mm) | Ogologo(mm) |

| 0.3 ~ 60 | ≥400 | ≤ 6000 | ||

| Titanium mpempe akwụkwọ | |||

| Ọkpụrụkpụ | akara ule | ||

| .016 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .020 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .025 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .032 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .040 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .050 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .063 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .071 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .080 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .090 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .100 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .125 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

Mara: Nha agbakwunyere dị, ọ bụghị nha niile egosiri dị na ngwaahịa.Biko kpọtụrụ anyị ka ịlele ịdị adị.

| AMS:AMS 2631, AMS 4901, AMS 4907, AMS 4911ASTM: ASTM B265 Gr 23, ASTM B265 Gr 5, ASTM B265 Gr2, ASTM B265 Gr4, ASTM F136, ASTM F67MIL-T:MIL-T-9046, MIL-T-9046 CP1EN:EN 10204.3, EN 1-204:2005 3.1 NACE:NACE MR0175 ASME:ASME SB265 |

| Ọkwa | Nkọwa AMS/MIL | Nkọwa ASTM |

| Nkeji 1 | AMS-T-9046B CP4 AMS 4940 MIL-T-9046J CP4 | ASTM B265 Gr1 mpempe akwụkwọ / efere ASTM B337 Gr1 ọkpọkọ ASTM B338 Gr1 tube ASTM B348 Gr1 mmanya ASTM F67 Gr1 Ịwa Ahụ |

| Nkeji 2 | Ọkwa 2 AMS-T-9046B CP3 AMS 4902 MIL-T-9046J CP3 AMS 4941 AMS 4942 AMS 4951 Welding waya | ASTM B265 Gr2 mpempe akwụkwọ / efere ASTM B337 Gr2 ọkpọkọ ASTM B338 Gr2 tube ASTM B348 Gr2 mmanya ASTM F67 Gr2 Ịwa Ahụ |

| Nkeji 3 | AMS-T-9046B CP2 AMS 4900 MIL-T-9046J CP2 | ASTM B265 Gr3 mpempe akwụkwọ/efere ASTM B337 Gr3 ọkpọkọ ASTM B338 Gr3 tube ASTM B348 Gr3 mmanya ASTM F67 Gr3 Ịwa Ahụ |

| Nkeji 4 | AMS-T-9046B CP1 AMS-T-9047A CP70 AMS 4901 AMS 4921 MIL-T-9046J CP1 MIL-T-9047G CP70 | ASTM B265 Gr4 mpempe akwụkwọ/efere ASTM B337 Gr4 ọkpọkọ ASTM B338 Gr4 tube ASTM B348 Gr4 mmanya ASTM F67 Gr4 Ịwa Ahụ |

| Nkeji 7 | ASTM B265 Gr7 mpempe akwụkwọ/efere ASTM B337 Gr7 ọkpọkọ ASTM B338 Gr7 tube ASTM B348 Gr7 mmanya |

| Ọkwa | Nkọwa US | Nkọwa ASTM |

| Ọkwa 5 6 Al-4V | AMS 4907 ELI AMS 4911 AMS 4928 AMS 4930 ELI AMS 4931 ELI Duplex ann AMS 4963 AMS 4965 AMS 4967 AMS 4985 AMS 4991 AMS 6931 AMS 6932 MIL-T-9046J AB-1 MIL-T-9046J AB-2 (ELI) MIL-T-9046H Ụdị 3 Comp C MIL-T-9046H Ụdị 3 Comp D AMS-T-9046B AB-1 AMS-T-9046B AB-2 (ELI) MIL-T-9047G 6Al-4v MIL-T-9047G 6Al-4v (ELI) AMS-T-9047A 6Al-4v AMS-T-9047A 6Al-4v (ELI) | ASTM B265 Gr5 mpempe akwụkwọ / efere ASTM B348 Gr5 mmanya ASTM F136 Gr5 Ntinye ọkwa |

| Ọkwa 9 3 Al-2.5V | AMS 4943 AMS 4944 AMS 4945 AMS-T-9046B AB-5 AMS-T-9047A 3Al-2.5V MIL-T-9046J AB-5 MIL-T-9047 3Al-2.5V | ASTM B265 Gr6 mpempe akwụkwọ/efere ASTM B348 Gr6 mmanya |

| Ọkwa 23 6Al-4V ELI | AMS 4907 AMS 4930 AMS 6932 AMS-T-9046 AB-2 6AL-4V (ELI) AMS-T-9047 AB-2 6AL-4V (ELI) MIL-T-9046 AB-2 6AL-4V (ELI) MIL-T-9047 6AL-4V (ELI) | ASTM B265 Gr23 mpempe akwụkwọ / efere / eriri ASTM B348 Gr23 mmanya/billet ASTM F136 Gr23 Implant Gra |

Ngwakọta kemịkalụ

| Ọkwa | Ngwakọta kemịkalụ, pasentị arọ (%) | ||||||||||||

| C ≤ | O ≤ | N ≤ | H ≤ | Fe ≤ | Al | V | Pd | Ru | Ni | Mo | Ihe ndị ọzọ Oke.nke ọ bụla | Ihe ndị ọzọ Oke.ngụkọta | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5~6.75 | 3.5~4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12~0.25 | - | 0.12~0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5~3.5 | 2.0~3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12~0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6~0.9 | 0.2~0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04~0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5~6.5 | 3.5~4.5 | - | - | - | - | 0.1 | 0.1 |

Njirimara anụ ahụ

| Ọkwa | Njirimara anụ ahụ | ||||||

| Ike tensile Min | Mpụta ike (0.2%, akwụ ụgwọ) | Elongation na 50mm Nkeji (%) | |||||

| ksi | MPa | Min | Oke | ||||

| ksi | MPa | ksi | MPa | ||||

| Gr1 | 35 | 240 | 20 | 138 | 45 | 310 | 24 |

| Gr2 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| Gr4 | 80 | 550 | 70 | 483 | 95 | 655 | 15 |

| Gr5 | 130 | 895 | 120 | 828 | - | - | 10 |

| Gr7 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| Gr9 | 90 | 620 | 70 | 483 | - | - | 15 |

| Gr11 | 35 | 240 | 20 | 138 | 45 | 310 | 24 |

| Gr12 | 70 | 483 | 50 | 345 | - | - | 18 |

| Gr16 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| Gr23 | 120 | 828 | 110 | 759 | - | - | 10 |

Ndigide (mm)

| Ọkpụrụkpụ | Ogologo ndidi | ||

| 400-1000 | 1000-2000 | 2000 | |

| 5.0-6.0 | ±0.35 | ±0.40 | ±0.60 |

| 6.0-8.0 | ±0.40 | ±0.60 | ± 0,80 |

| 8.0 ruo 10.0 | ±0.50 | ±0.60 | ± 0,80 |

| 10.0 ~ 15.0 | ± 0,70 | ± 0,80 | ± 1.00 |

| 15.0-20.0 | ± 0,70 | ±0.90 | ± 1.10 |

| 20.0 ~ 30.0 | ±0.90 | ± 1.00 | ± 1.20 |

| 30-40.0 | ± 1.10 | ± 1.20 | ± 1.50 |

| 40-50.0 | ± 1.20 | ± 1.50 | ± 2.00 |

| 50-60.0 | ± 1.60 | ± 2.00 | ± 2.50 |