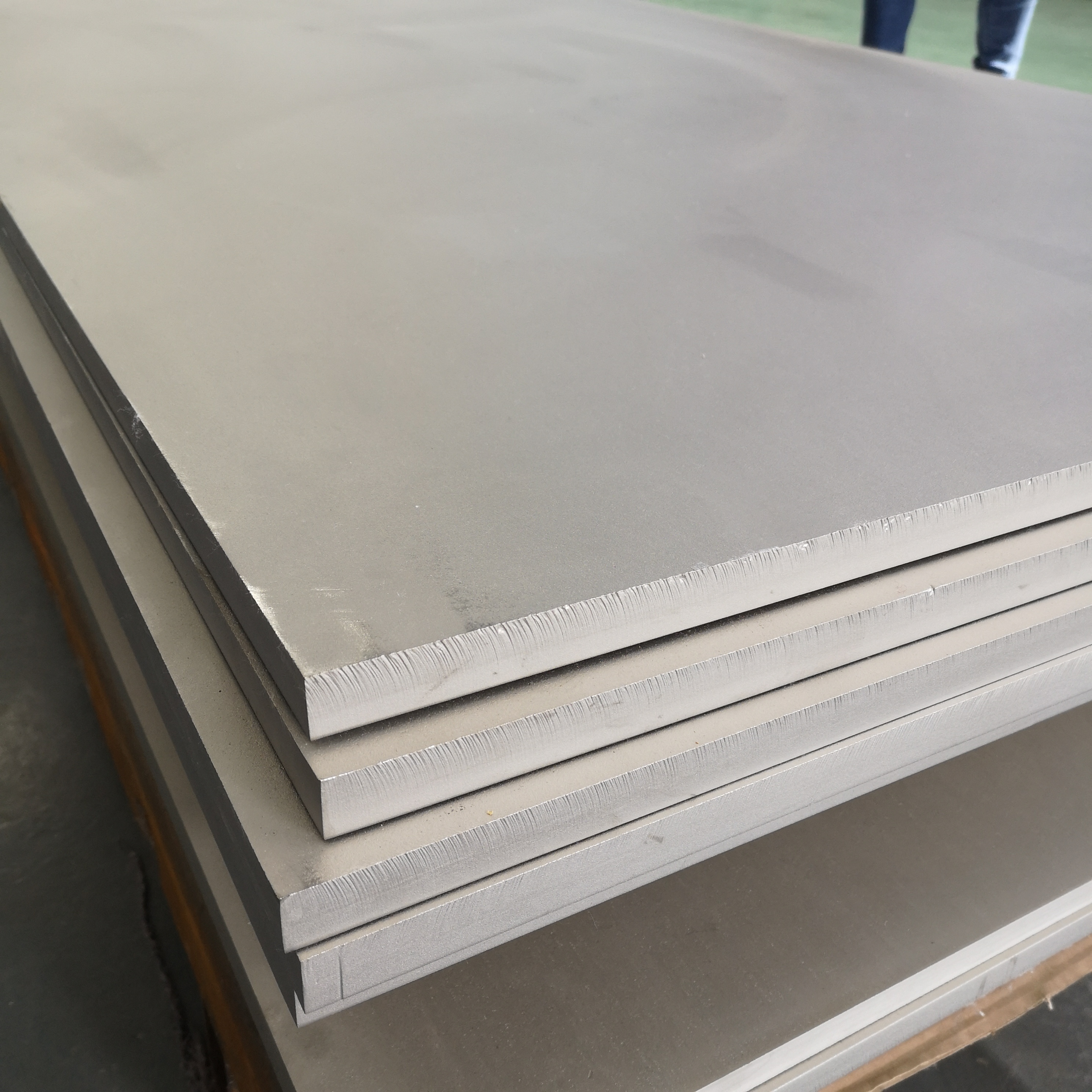

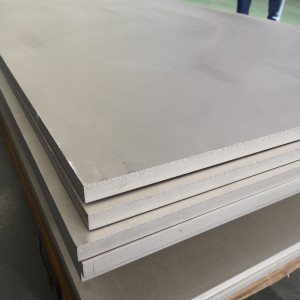

Lambaran Titanium / Lempeng

Kelas umum

Titanium Kelas 1mangrupa unalloyed, produk titanium kakuatan low ngandung oksigén low kalawan kamampuhan formulir tinggi;kelas titanium ieu dipaké dina pigura hawa, bursa panas sarta unit desalination.

Titanium Kelas 2mangrupa unalloyed, produk titanium kakuatan sedeng.kelas titanium ieu dipaké dina pigura hawa, mesin pesawat jeung bagian laut;pangabisa weld alus sarta lalawanan korosi mangrupakeun ciri distinguishing na.

Titanium Kelas 3mangrupa unalloyed, kakuatan tinggi, produk titanium nyadiakeun lalawanan korosi alus teuing jeung kamampuh weld alus.Kelas titanium ieu utamana dipaké dina pigura hawa jeung bagian mesin pesawat.

Titanium Kelas 4nyaeta kakuatan pangluhurna murni produk titanium unalloyed.Kelas titanium ieu dipaké ampir éksklusif pikeun pigura hawa, bagian mesin pesawat, laut, implants bedah, tubing hidrolik.Kamampuhan bentuk anu saé sareng résistansi korosi mangrupikeun ciri khasna.

Titanium Kelas 5 (6AL-4V)mangrupa produk titanium alloyed ngandung 6% Aluminium jeung 4% Vanadium;mangrupa produk kakuatan sedeng.kelas titanium ieu utamana dipaké dina airframe jeung bagian mesin turbin;sarta pikeun dipaké dina implants bedah.Inpo teknis Titanium 6AL–4V ELI mangrupa produk titanium alloyed ngandung 6% Aluminium jeung 4% Vanadium, ELI (Extra Low Interstitial).

6AL–2Sn–4Zr–2Bulan (6-2-4-2)mangrupa produk titanium alloyed ngandung 6% Aluminium, 2% Tin, 4% Zirconium, 2% Molybdenum.

6AL–6V–2Sn (6-6-2)mangrupa produk titanium alloyed ngandung 6% Aluminium, 6% Vanadium, 2% Tin.

5AL–2.5Sn & ELI (5-2.5)mangrupa produk titanium alloyed ngandung 5% Aluminium jeung 2,5% Tin.Ogé ELI (Extra Low Interstitial).

8AL–1V–1Bulan (8-1-1)mangrupa produk titanium alloyed ngandung 8% Aluminium, 1% Molybdenum jeung 1% Vanadium.

15V–3Cr–4AL–3Sn (15-3-4-3)mangrupa produk titanium alloyed ngandung 15% Vanadium, 3% Chromium, 4% Aluminium, 3% Tin.

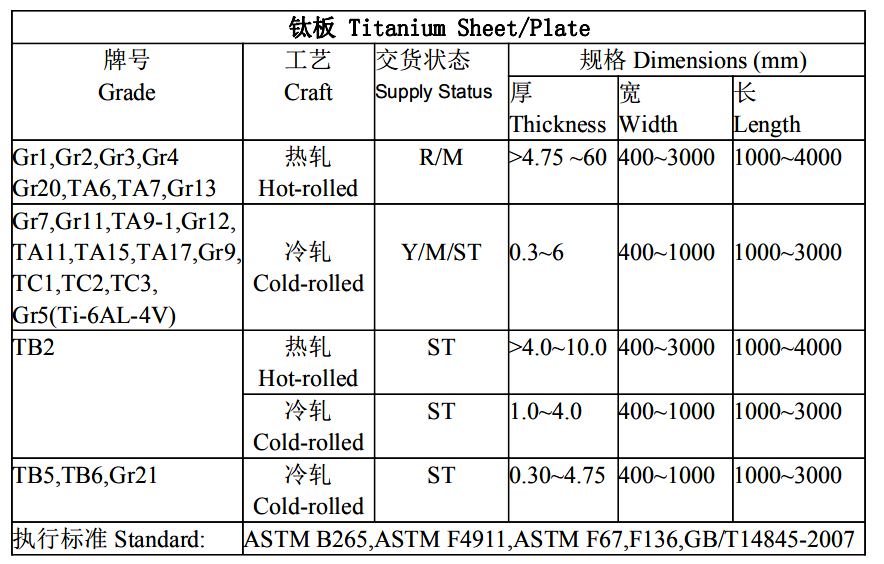

| Kelas | Status | Spésifikasi | ||

| Gr1, Gr2, Gr4, Gr5, Gr7, Gr9, Gr11, Gr12, Gr16, Gr23 | Hot Rolled (R) Cold Rolled(Y) Annealed(M) Pangobatan solusi (ST) | Ketebalan (mm) | Lebar (mm) | Panjangna (mm) |

| 0.3~60 | ≥400 | ≤ 6000 | ||

| Lambaran titanium | |||

| Kandelna | Sasmita | ||

| .016 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .020 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .025 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .032 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .040 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .050 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .063 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .071 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .080 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .090 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .100 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .125 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

Catetan: Ukuran tambahan sayogi, henteu sadayana ukuran anu ditampilkeun sayogi tina saham.Mangga ngahubungan kami pikeun pariksa kasadiaan.

| AMS:AMS 2631, AMS 4901, AMS 4907, AMS 4911ASTM: ASTM B265 Gr 23, ASTM B265 Gr 5, ASTM B265 Gr2, ASTM B265 Gr4, ASTM F136, ASTM F67MIL-T:MIL-T-9046, MIL-T-9046 CP1EN:EN 10204.3, EN 1-204:2005 3.1 NACE:NACE MR0175 ASME:ASME SB265 |

| Kelas | Spésifikasi AMS/MIL | Spésifikasi ASTM |

| Kelas 1 | AMS-T-9046B CP4 AMS 4940 MIL-T-9046J CP4 | ASTM B265 Gr1 Lambaran/piring Pipa ASTM B337 Gr1 pipah ASTM B338 Gr1 ASTM B348 Gr1 bar ASTM F67 Gr1 Implan Bedah |

| Kelas 2 | Kelas 2 AMS-T-9046B CP3 AMS 4902 MIL-T-9046J CP3 AMS 4941 AMS 4942 AMS 4951 kawat las | ASTM B265 Gr2 Lambaran/piring Pipa ASTM B337 Gr2 pipah ASTM B338 Gr2 ASTM B348 Gr2 bar ASTM F67 Gr2 Implan Bedah |

| Kelas 3 | AMS-T-9046B CP2 AMS 4900 MIL-T-9046J CP2 | ASTM B265 Gr3 Lambaran / piring Pipa ASTM B337 Gr3 pipah ASTM B338 Gr3 ASTM B348 Gr3 bar ASTM F67 Gr3 Implan Bedah |

| Kelas 4 | AMS-T-9046B CP1 AMS-T-9047A CP70 AMS 4901 AMS 4921 MIL-T-9046J CP1 MIL-T-9047G CP70 | ASTM B265 Gr4 Lambaran/piring Pipa ASTM B337 Gr4 pipah ASTM B338 Gr4 ASTM B348 Gr4 bar ASTM F67 Gr4 Implan Bedah |

| Kelas 7 | ASTM B265 Gr7 Lambaran/piring Pipa ASTM B337 Gr7 pipah ASTM B338 Gr7 ASTM B348 Gr7 bar |

| Kelas | Spésifikasi AS | Spésifikasi ASTM |

| Kelas 5 6Al-4V | AMS 4907 ELI AMS 4911 AMS 4928 AMS 4930 ELI AMS 4931 ELI Duplex ann AMS 4963 AMS 4965 AMS 4967 AMS 4985 AMS 4991 AMS 6931 AMS 6932 MIL-T-9046J AB-1 MIL-T-9046J AB-2 (ELI) MIL-T-9046H Tipe 3 Comp C MIL-T-9046H Tipe 3 Comp D AMS-T-9046B AB-1 AMS-T-9046B AB-2 (ELI) MIL-T-9047G 6Al-4v MIL-T-9047G 6Al-4v (ELI) AMS-T-9047A 6Al-4v AMS-T-9047A 6Al-4v (ELI) | ASTM B265 Gr5 Lambaran/piring ASTM B348 Gr5 bar ASTM F136 Gr5 Implant Kelas |

| Kelas 9 3Al-2.5V | AMS 4943 AMS 4944 AMS 4945 AMS-T-9046B AB-5 AMS-T-9047A 3Al-2.5V MIL-T-9046J AB-5 MIL-T-9047 3Al-2.5V | ASTM B265 Gr6 Lambaran/piring ASTM B348 Gr6 bar |

| Kelas 23 6Al-4V ELI | AMS 4907 AMS 4930 AMS 6932 AMS-T-9046 AB-2 6AL-4V (ELI) AMS-T-9047 AB-2 6AL-4V (ELI) MIL-T-9046 AB-2 6AL-4V (ELI) MIL-T-9047 6AL-4V (ELI) | ASTM B265 Gr23 lembar / piring / strip ASTM B348 Gr23 bar / billet ASTM F136 Gr23 susuk Gra |

Komposisi kimiawi

| Kelas | Komposisi kimia, persén beurat (%) | ||||||||||||

| C ≤ | O ≤ | N ≤ | H ≤ | Fe ≤ | Al | V | Pd | Ru | Ni | Mo | Unsur séjén Max.masing-masing | Unsur séjén Max.total | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0,015 | 0.20 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0,015 | 0.30 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0,015 | 0.30 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0,015 | 0.40 | 5.5~6.75 | 3.5~4.5 | — | — | — | — | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0,015 | 0.30 | — | — | 0.12~0.25 | — | 0.12~0.25 | — | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0,015 | 0.25 | 2.5~3.5 | 2.0~3.0 | — | — | — | — | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | — | — | 0.12~0.25 | — | — | — | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | — | — | — | — | 0.6~0.9 | 0.2~0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | — | — | 0.04~0.08 | — | — | — | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5~6.5 | 3.5~4.5 | — | — | — | — | 0.1 | 0.1 |

sipat fisik

| Kelas | sipat fisik | ||||||

| Kakuatan tensile Min | kakuatan ngahasilkeun (0,2%, offset) | Elongation dina 50mm Min (%) | |||||

| ksi | MPa | Min | Max | ||||

| ksi | MPa | ksi | MPa | ||||

| Gr1 | 35 | 240 | 20 | 138 | 45 | 310 | 24 |

| Gr2 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| Gr4 | 80 | 550 | 70 | 483 | 95 | 655 | 15 |

| Gr5 | 130 | 895 | 120 | 828 | — | — | 10 |

| Gr7 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| Gr9 | 90 | 620 | 70 | 483 | — | — | 15 |

| Gr11 | 35 | 240 | 20 | 138 | 45 | 310 | 24 |

| Gr12 | 70 | 483 | 50 | 345 | — | — | 18 |

| Gr16 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| Gr23 | 120 | 828 | 110 | 759 | — | — | 10 |

Kasabaran (mm)

| Kandelna | kasabaran lebar | ||

| 400~1000 | 1000~2000 | > 2000 | |

| 5.0~6.0 | ± 0,35 | ± 0,40 | ± 0,60 |

| 6.0~8.0 | ± 0,40 | ± 0,60 | ± 0,80 |

| 8.0~10.0 | ± 0,50 | ± 0,60 | ± 0,80 |

| 10.0~15.0 | ± 0,70 | ± 0,80 | ± 1.00 |

| 15.0~20.0 | ± 0,70 | ± 0,90 | ± 1.10 |

| 20.0~30.0 | ± 0,90 | ± 1.00 | ± 1.20 |

| 30.0~40.0 | ± 1.10 | ± 1.20 | ± 1,50 |

| 40.0~50.0 | ± 1.20 | ± 1,50 | ± 2.00 |

| 50.0~60.0 | ± 1,60 | ± 2.00 | ± 2,50 |