Titanium Ring

Large titanium rings are manufactured by the large grinding ring machine, small titanium rings can be achieved by forging machine. As a company with more than 20 years of production experience, we have a series of rigorous forging process and operation manual, including the heating steps, heating time and heat preservation time. The 35MN and 16MN rapid forging machine guaranteed the multiple forging in the suitable temperature range, and changed the internal physical structure of titanium rings. Greatly improved the quality of our products.

In addition to titanium ring, we also provide the production of titanium disc, titanium block etc.

|

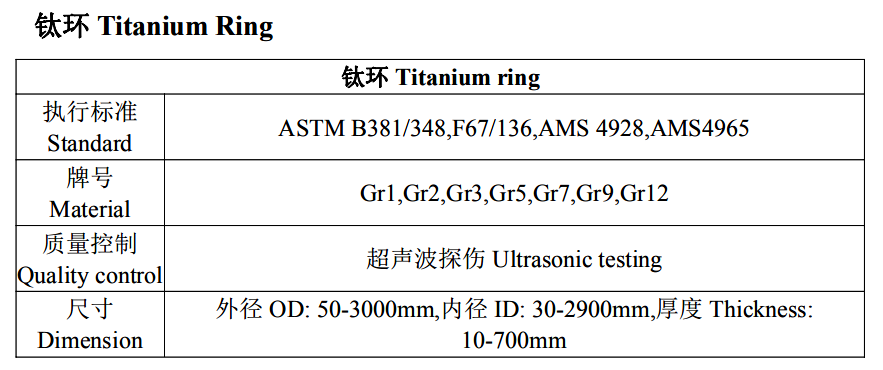

product name |

Titanium Ring |

|

Size |

OD(max3000mm)×ID(max2900mm)×length(maximum length 1000mm) |

|

Grade |

TA1/TA2/TA5/TA6/TA9/TA10/TA15/TA19/TC1/TC2/TC4/TC11/ GR1/GR2/GR5/GR7/GR9/GR12/GR23 |

|

Standards |

ASTM B381/348,F67/136,AMS4928,AMS4965,AMS,MIL,DIN,BS,JIS,GB / T,ISO etc |

|

Density |

4.51g / cm3 High performance industrial forging, gr12 Titanium forged rolling ring |

|

Technology |

Forging, rolling, grinding high performance industrial forging GR12 titanium forging rolling ring |

|

Type |

The process of seamless ring rolling involves cutting a hole in the forged material and rolling it into a thin ring. Compared to plate firing or butt welding, the rolled forged ring provides a concentric improvement with a smooth surface ring Ring high performance industrially forged GR12 titanium forged rolling ring |

| Application | 1. Electroplating;2. Chemical and petrochemical technology;3. Medical high performance industrial forging GR12 titanium forging rolling ring |

ASTM B381/348,F67/136,AMS4928,AMS4965

Chemical composition

|

Grade |

Chemical composition, weight percent (%) |

||||||||||||

|

C (≤) |

O (≤) |

N (≤) |

H (≤) |

Fe (≤) |

Al |

V |

Pd |

Ru |

Ni |

Mo |

Other Elements Max. each |

Other Elements Max. total |

|

|

Gr1 |

0.08 |

0.18 |

0.03 |

0.015 |

0.20 |

— |

— |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr2 |

0.08 |

0.25 |

0.03 |

0.015 |

0.30 |

— |

— |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr4 |

0.08 |

0.25 |

0.03 |

0.015 |

0.30 |

— |

— |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr5 |

0.08 |

0.20 |

0.05 |

0.015 |

0.40 |

5.5~6.75 |

3.5~4.5 |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr7 |

0.08 |

0.25 |

0.03 |

0.015 |

0.30 |

— |

— |

0.12~0.25 |

— |

0.12~0.25 |

— |

0.1 |

0.4 |

|

Gr9 |

0.08 |

0.15 |

0.03 |

0.015 |

0.25 |

2.5~3.5 |

2.0~3.0 |

— |

— |

— |

— |

0.1 |

0.4 |

|

Gr11 |

0.08 |

0.18 |

0.03 |

0.15 |

0.2 |

— |

— |

0.12~0.25 |

— |

— |

— |

0.1 |

0.4 |

|

Gr12 |

0.08 |

0.25 |

0.03 |

0.15 |

0.3 |

— |

— |

— |

— |

0.6~0.9 |

0.2~0.4 |

0.1 |

0.4 |

|

Gr16 |

0.08 |

0.25 |

0.03 |

0.15 |

0.3 |

— |

— |

0.04~0.08 |

— |

— |

— |

0.1 |

0.4 |

|

Gr23 |

0.08 |

0.13 |

0.03 |

0.125 |

0.25 |

5.5~6.5 |

3.5~4.5 |

— |

— |

— |

— |

0.1 |

0.1 |

Physical properties

|

Grade |

Physical properties |

|||||

|

Tensile strength Min |

Yield strength Min (0.2%, offset) |

Elongation in 4D Min (%) |

Reduction of Area Min (%) |

|||

|

ksi |

MPa |

ksi |

MPa |

|||

|

Gr1 |

35 |

240 |

20 |

138 |

24 |

30 |

|

Gr2 |

50 |

345 |

40 |

275 |

20 |

30 |

|

Gr4 |

80 |

550 |

70 |

483 |

15 |

25 |

|

Gr5 |

130 |

895 |

120 |

828 |

10 |

25 |

|

Gr7 |

50 |

345 |

40 |

275 |

20 |

30 |

|

Gr9 |

90 |

620 |

70 |

483 |

15 |

25 |

|

Gr11 |

35 |

240 |

20 |

138 |

24 |

30 |

|

Gr12 |

70 |

483 |

50 |

345 |

18 |

25 |

|

Gr16 |

50 |

345 |

40 |

275 |

20 |

30 |

|

Gr23 |

120 |

828 |

110 |

759 |

10 |

15 |