Titanium Pipe / Tube

Titanium seamless tube wurdt ferwurke troch de ôfbraak fan titanium ingot, extruding nei titanium tube billet.Produsearje dan titaniumbuizen nei passende grutte mei searjes fan prosessen lykas meardere rôljen, annealing, beitsen en slyptechnology.

Titanium laske buis is troch it selektearjen fan in geskikte dikte fan 'e hege kwaliteit kâld rôle titanium plaat, nei it proses fan flatten, snijden en waskjen, dan oprôle titanium plaat yn tubular, welding troch de heule automatyske welding-apparatuer.Us avansearre welding apparatuer garandearre de kwaliteit fan welding.Uteinlik helpe om de titaniumbuis fan poerbêste kwaliteit te produsearjen.

Titanium naadleaze buis

Klasse: Gr1, Gr2, Gr7, Gr9, Gr11, Gr12, Gr16 ensfh

Buitendiameter: 3 ~ 110 mm

Muorre dikte: 0.1~5.5mm

Lengte: ≤19000mm

Titanium weld buis

Klasse: Gr1, Gr2, Gr7, Gr9, Gr11, Gr12, Gr16 ensfh

Outer diameter: 10 ~ 1000mm

Muorre dikte: 0.5~5.5mm

Lengte: ≤19000mm

Gr5, Gr23 titanium alloy naadleaze buis

Buitendiameter: 20 ~ 110 mm

Muorre dikte: 1~50mm

Lengte: ≤3000mm

Manufacturing proses: Boarjen, Hot Rolling

| SEAMLESS TITANIUM PIPE | ||||||||||

|

| S10 | S40 | S80 | |||||||

| Pipe Grutte | OD | Muorre | Binnen Dia. | lbs/ft | Muorre | Binnen Dia. | lbs/ft | Muorre | Binnen Dia. | lbs/ft |

| 1/8 | .405 | .049 | .307 | .1072 | .068 | .269 | .1408 | .095 | .215 | .1810 |

| 1/4 | .540 | .065 | .410 | .1897 | .088 | .364 | .2442 | .119 | .302 | .3079 |

| 3/8 | .675 | .065 | .545 | .2437 | .091 | .493 | .3266 | .126 | .423 | .4251 |

| 1/2 | .840 | .083 | .674 | .3861 | .109 | .622 | .4896 | .147 | .546 | .6260 |

| 3/4 | 1.050 | .083 | .884 | .4932 | .113 | .824 | .6506 | .154 | .742 | .8479 |

| 1 | 1.315 | .109 | 1.097 | .8078 | .133 | 1.049 | .9660 | .179 | .957 | 1.2495 |

| 1-1/4 | 1.660 | .109 | 1.442 | 1.0389 | .140 | 1.380 | 1.3077 | .191 | 1.278 | 1.7242 |

| 1-1/2 | 1.900 | .109 | 1.681 | 1.1996 | .145 | 1.610 | 1.5637 | .200 | 1.500 | 2.0893 |

| 2 | 2.375 | .109 | 2.157 | 1.5178 | .154 | 2.067 | 2.1018 | .218 | 1.939 | 2.8895 |

| 2-1/2 | 2.875 | .120 | 2.635 | 2.0315 | .203 | 2.469 | 3.3331 | .276 | 2.323 | 4.4080 |

| 3 | 3.500 | .120 | 3.260 | 2.4924 | .216 | 3.068 | 4.3589 | .300 | 2.900 | 5.8992 |

| 3-1/2 | 4.000 | .120 | 3.760 | 2.8611 | .226 | 3.548 | 5.2412 | .318 | 3.364 | 7.1950 |

| 4 | 4.500 | .120 | 4.260 | 3.2298 | .237 | 4.026 | 6.2085 | .337 | 3.826 | 8.6210 |

| 5 | 5.563 | .134 | 5.295 | 4.4704 | .258 | 5.047 | 8.4106 | .375 | 4.813 | 11.9550 |

| 6 | 6.625 | .134 | 6.357 | 5.3449 | .280 | 6.065 | 10.917 | .432 | 5.761 | 16.440 |

| WELDED TITANIUM PIPE | |||||||

|

| S10 | S40 | |||||

| Pipe Grutte | OD | Muorre | Binnen Dia. | lbs/ft | Muorre | Binnen Dia. | lbs/ft |

| 3/4 | .1.050 | .083 | .884 | .4932 | .113 | .824 | .6506 |

| 1 | 1.315 | .109 | 1.097 | .8078 | .133 | 1.049 | .9660 |

| 1-1/4 | 1.660 | .109 | 1.442 | 1.0389 | .140 | 1.380 | 1.3077 |

| 1-1/2 | 1.900 | .109 | 1.681 | 1.1996 | .145 | 1.610 | 1.5637 |

| 2 | 2.375 | .109 | 2.157 | 1.5178 | .154 | 2.067 | 2.1018 |

| 2-1/2 | 2.875 | .120 | 2.635 | 2.0315 | .203 | 2.469 | 3.3331 |

| 3 | 3.500 | .120 | 3.260 | 2.4924 | .216 | 3.068 | 4.3589 |

| 3-1/2 | 4.000 | .120 | 3.760 | 2.8611 | .226 | 3.548 | 5.2412 |

| 4 | 4.500 | .120 | 4.260 | 3.2298 | .237 | 4.026 | 6.2085 |

| 5 | 5.563 | .134 | 5.295 | 4.4704 | .258 | 5.047 | 8.4106 |

| 6 | 6.625 | .134 | 6.357 | 5.3449 | .280 | 6.065 | 10.917 |

| 8 | 8.625 | .148 | 8.329 | 7.7095 | .322 | 7.981 | 16.429 |

| 10 | 10.750 | .165 | 10.420 | 10.732 | .365 | 10.020 | 23.293 |

| 12 | 12.750 | .180 | 12.390 | 13.904 | .375 | 12.000 | 28.517 |

| 14 | 14.000 | .188 | 13.624 | 15.956 | .375 | 13.250 | 31.397 |

| 16 | 16.000 | .188 | 15.624 | 18.267 | .375 | 15.250 | 36.006 |

| 18 | 18.000 | .188 | 17.624 | 20.577 | .375 | 17.250 | 40.615 |

| 20 | 20.000 | .218 | 19.564 | 26.500 | .375 | 19.250 | 45.223 |

| 24 | 24.000 | .250 | 23.500 | 36.486 | .375 | 23.250 | 54.441 |

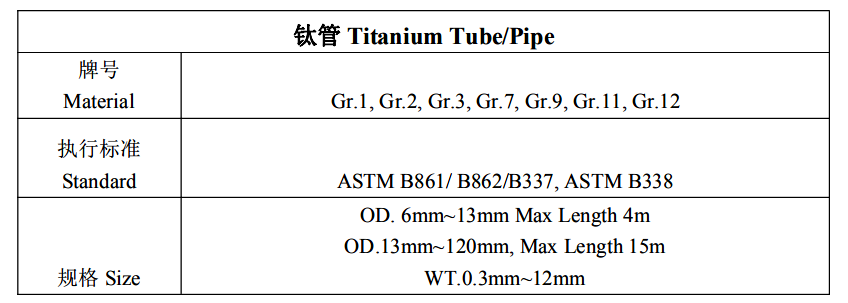

ASTM B338 - 10e1 Standertspesifikaasje foar naadleaze en laske buizen fan titanium en titaniumlegering foar kondensers en waarmtewikselers

ASTM B862 - 09 Standert spesifikaasje foar titanium en titanium alloy laske piip

ASTM B861 - 10 Standert spesifikaasje foar naadleaze piip fan titanium en titaniumlegering, ASTM B337

| Titanium Tube / Pipe | Produkt Namme | Klasse | Spesifikaasje (mm) | Standert |

| Naadleaze Tube | Gr.1 Gr.2 Gr.7 Gr.9 Gr.12

| OD(3-114)×THK(0,5-10) ×≤ lingte 12000 | ASTM B337 ASTM B338 ASTM B 861 | |

| Welding Pipe | Gr.1 Gr.2 Gr.7 Gr.12 | ≥OD133 | ASTM B862 | |

| Tube (Ruslân) | BT1-0 | OD(3-114)×THK(0,5-10) ×≤ lingte 12000 | GOST 22879 | |

Gemyske gearstalling

| Klasse | Gemyske gearstalling, gewicht persintaazje (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Oare eleminten Max.elk | Oare eleminten Max.totaal | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5-6.75 | 3.5-4.5 | - | - | - | - | 0.1 | 0.4 |

| gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12 ~ 0.25 | - | 0.12 ~ 0.25 | - | 0.1 | 0.4 |

| gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5-3.5 | 2.0-3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12 ~ 0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6 ~ 0.9 | 0.2~0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04-0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5-6.5 | 3.5-4.5 | - | - | - | - | 0.1 | 0.1 |

Fysike eigenskippen

| Klasse | Fysike eigenskippen | ||||

| Treksterkte Min | Yield sterkte Min (0.2%, offset) | Ferlinging yn 2in of 50mm Min (%) | |||

| ksi | MPa | ksi | MPa | ||

| Gr1 | 35 | 240 | 20 | 138 | 24 |

| Gr2 | 50 | 345 | 40 | 275 | 20 |

| Gr5 | 130 | 895 | 120 | 828 | 10 |

| gr7 | 50 | 345 | 40 | 275 | 20 |

| gr9 | 90 | 620 | 70 | 483 | 15 |

| Gr11 | 35 | 240 | 20 | 138 | 24 |

| Gr12 | 70 | 483 | 50 | 345 | 18 |

| Gr16 | 50 | 345 | 40 | 275 | 20 |

| Gr23 | 120 | 828 | 110 | 759 | 10 |