Titanium Pipe/Tube

Ang titanium seamless tube ay pinoproseso sa pamamagitan ng pagkasira ng titanium ingot, extruding sa titanium tube billet.Pagkatapos ay gumawa ng mga titanium tubes sa naaangkop na laki na may serye ng mga proseso tulad ng maraming rolling, annealing, pickling, at grinding technology.

Ang titanium welded tube ay sa pamamagitan ng pagpili ng angkop na kapal ng mataas na kalidad na cold rolled titanium plate, pagkatapos ng proseso ng pagyupi, pagputol at paghuhugas, pagkatapos ay pinagsama ang titanium plate sa tubular, hinang ng buong awtomatikong kagamitan sa hinang.Ginagarantiyahan ng aming advanced na kagamitan sa hinang ang kalidad ng hinang.Sa huli ay tumulong upang makabuo ng mahusay na kalidad ng titanium tube.

Titanium na walang tahi na tubo

Grado: Gr1, Gr2, Gr7, Gr9, Gr11, Gr12, Gr16 atbp

Panlabas na diameter: 3~110mm

Kapal ng pader: 0.1~5.5mm

Haba: ≤19000mm

Titanium weld tube

Grado: Gr1, Gr2, Gr7, Gr9, Gr11, Gr12, Gr16 atbp

Panlabas na diameter: 10~1000mm

Kapal ng pader: 0.5~5.5mm

Haba: ≤19000mm

Gr5, Gr23 titanium alloy seamless tube

Panlabas na diameter: 20~110mm

Kapal ng pader: 1~50mm

Haba: ≤3000mm

Proseso ng paggawa: Pagbabarena, Hot Rolling

| SEAMLESS TITANIUM PIPE | ||||||||||

|

| S10 | S40 | S80 | |||||||

| Sukat ng Pipe | OD | Pader | Sa loob ni Dia. | lbs / ft | Pader | Sa loob ni Dia. | lbs / ft | Pader | Sa loob ni Dia. | lbs / ft |

| 1/8 | .405 | .049 | .307 | .1072 | .068 | .269 | .1408 | .095 | .215 | .1810 |

| 1/4 | .540 | .065 | .410 | .1897 | .088 | .364 | .2442 | .119 | .302 | .3079 |

| 3/8 | .675 | .065 | .545 | .2437 | .091 | .493 | .3266 | .126 | .423 | .4251 |

| 1/2 | .840 | .083 | .674 | .3861 | .109 | .622 | .4896 | .147 | .546 | .6260 |

| 3/4 | 1.050 | .083 | .884 | .4932 | .113 | .824 | .6506 | .154 | .742 | .8479 |

| 1 | 1.315 | .109 | 1.097 | .8078 | .133 | 1.049 | .9660 | .179 | .957 | 1.2495 |

| 1-1/4 | 1.660 | .109 | 1.442 | 1.0389 | .140 | 1.380 | 1.3077 | .191 | 1.278 | 1.7242 |

| 1-1/2 | 1.900 | .109 | 1.681 | 1.1996 | .145 | 1.610 | 1.5637 | .200 | 1.500 | 2.0893 |

| 2 | 2.375 | .109 | 2.157 | 1.5178 | .154 | 2.067 | 2.1018 | .218 | 1.939 | 2.8895 |

| 2-1/2 | 2.875 | .120 | 2.635 | 2.0315 | .203 | 2.469 | 3.3331 | .276 | 2.323 | 4.4080 |

| 3 | 3.500 | .120 | 3.260 | 2.4924 | .216 | 3.068 | 4.3589 | .300 | 2.900 | 5.8992 |

| 3-1/2 | 4.000 | .120 | 3.760 | 2.8611 | .226 | 3.548 | 5.2412 | .318 | 3.364 | 7.1950 |

| 4 | 4.500 | .120 | 4.260 | 3.2298 | .237 | 4.026 | 6.2085 | .337 | 3.826 | 8.6210 |

| 5 | 5.563 | .134 | 5.295 | 4.4704 | .258 | 5.047 | 8.4106 | .375 | 4.813 | 11.9550 |

| 6 | 6.625 | .134 | 6.357 | 5.3449 | .280 | 6.065 | 10.917 | .432 | 5.761 | 16.440 |

| WELDED TITANIUM PIPE | |||||||

|

| S10 | S40 | |||||

| Sukat ng Pipe | OD | Pader | Sa loob ni Dia. | lbs / ft | Pader | Sa loob ni Dia. | lbs / ft |

| 3/4 | .1.050 | .083 | .884 | .4932 | .113 | .824 | .6506 |

| 1 | 1.315 | .109 | 1.097 | .8078 | .133 | 1.049 | .9660 |

| 1-1/4 | 1.660 | .109 | 1.442 | 1.0389 | .140 | 1.380 | 1.3077 |

| 1-1/2 | 1.900 | .109 | 1.681 | 1.1996 | .145 | 1.610 | 1.5637 |

| 2 | 2.375 | .109 | 2.157 | 1.5178 | .154 | 2.067 | 2.1018 |

| 2-1/2 | 2.875 | .120 | 2.635 | 2.0315 | .203 | 2.469 | 3.3331 |

| 3 | 3.500 | .120 | 3.260 | 2.4924 | .216 | 3.068 | 4.3589 |

| 3-1/2 | 4.000 | .120 | 3.760 | 2.8611 | .226 | 3.548 | 5.2412 |

| 4 | 4.500 | .120 | 4.260 | 3.2298 | .237 | 4.026 | 6.2085 |

| 5 | 5.563 | .134 | 5.295 | 4.4704 | .258 | 5.047 | 8.4106 |

| 6 | 6.625 | .134 | 6.357 | 5.3449 | .280 | 6.065 | 10.917 |

| 8 | 8.625 | .148 | 8.329 | 7.7095 | .322 | 7.981 | 16.429 |

| 10 | 10.750 | .165 | 10.420 | 10.732 | .365 | 10.020 | 23.293 |

| 12 | 12.750 | .180 | 12.390 | 13.904 | .375 | 12.000 | 28.517 |

| 14 | 14.000 | .188 | 13.624 | 15.956 | .375 | 13.250 | 31.397 |

| 16 | 16.000 | .188 | 15.624 | 18.267 | .375 | 15.250 | 36.006 |

| 18 | 18.000 | .188 | 17.624 | 20.577 | .375 | 17.250 | 40.615 |

| 20 | 20,000 | .218 | 19.564 | 26.500 | .375 | 19.250 | 45.223 |

| 24 | 24.000 | .250 | 23.500 | 36.486 | .375 | 23.250 | 54.441 |

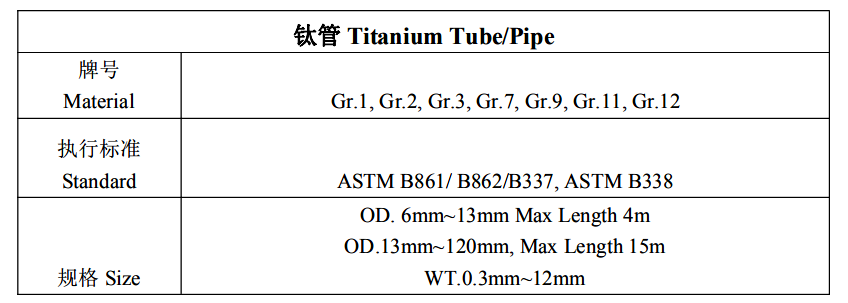

ASTM B338 – 10e1 Standard Specification para sa Seamless at Welded Titanium at Titanium Alloy Tubes para sa Condensers at Heat Exchanger

ASTM B862 – 09 Standard na Pagtutukoy para sa Titanium at Titanium Alloy Welded Pipe

ASTM B861 – 10 Standard na Pagtutukoy para sa Titanium at Titanium Alloy Seamless Pipe, ASTM B337

| Titanium Tube / Pipe | Pangalan ng Produkto | Grade | Detalye(mm) | Pamantayan |

| Walang tahi na Tube | Gr.1 Gr.2 Gr.7 Gr.9 Gr.12

| OD(3-114)×THK(0.5-10) ×≤ haba 12000 | ASTM B337 ASTM B338 ASTM B 861 | |

| Welding Pipe | Gr.1 Gr.2 Gr.7 Gr.12 | ≥OD133 | ASTM B862 | |

| Tube(Russia) | BT1-0 | OD(3-114)×THK(0.5-10) ×≤ haba 12000 | GOST22879 | |

Komposisyong kemikal

| Grade | Komposisyon ng kemikal, porsyento ng timbang (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Iba pang Elemento Max.bawat isa | Iba pang Elemento Max.kabuuan | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5~6.75 | 3.5~4.5 | — | — | — | — | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | — | — | 0.12~0.25 | — | 0.12~0.25 | — | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5~3.5 | 2.0~3.0 | — | — | — | — | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | — | — | 0.12~0.25 | — | — | — | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | — | — | — | — | 0.6~0.9 | 0.2~0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | — | — | 0.04~0.08 | — | — | — | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5~6.5 | 3.5~4.5 | — | — | — | — | 0.1 | 0.1 |

Mga katangiang pisikal

| Grade | Mga katangiang pisikal | ||||

| lakas ng makunat Min | lakas ng ani Min (0.2%, offset) | Pagpahaba sa 2in o 50mm Min (%) | |||

| ksi | MPa | ksi | MPa | ||

| Gr1 | 35 | 240 | 20 | 138 | 24 |

| Gr2 | 50 | 345 | 40 | 275 | 20 |

| Gr5 | 130 | 895 | 120 | 828 | 10 |

| Gr7 | 50 | 345 | 40 | 275 | 20 |

| Gr9 | 90 | 620 | 70 | 483 | 15 |

| Gr11 | 35 | 240 | 20 | 138 | 24 |

| Gr12 | 70 | 483 | 50 | 345 | 18 |

| Gr16 | 50 | 345 | 40 | 275 | 20 |

| Gr23 | 120 | 828 | 110 | 759 | 10 |