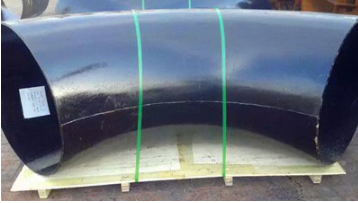

Gokora

Seamless Elbow Manufacturing process (Kupeta Kupisa & Kutonhora Kubhenda)

Imwe yedzakajairika nzira dzekugadzira magokora kushandisa inopisa mandrel kukotama kubva kune yakatwasuka simbi pombi.Mushure mekupisa pombi yesimbi pakupisa kwakakwirira, pombi inosundirwa, yakawedzerwa, yakakotamiswa nemidziyo yemukati ye mandrel nhanho nhanho.Kuisa inopisa mandrel bending kunogona kugadzira yakakura saizi renji isina musono gokora.Hunhu hwemandrel kukotama hunoenderana zvakanyanya neiyo yakabatanidzwa chimiro uye zviyero zve mandrel.Iko kushandisa zvakanakira kupisa kwekupeta magokora kunosanganisira kutsauka kweukobvu kudiki uye yakasimba kubhenda radius pane imwe bending methond mhando.Zvichakadaro, kushandisa kupeta panzvimbo pemabhenji ekare kunoderedza huwandu hwemawelds anodiwa.Izvi zvinoderedza kuwanda kwebasa rinodiwa uye zvinowedzera kunaka uye kushandiswa kwepombi.Nekudaro, kukotama kunotonhora maitiro ekukotamisa pombi yesimbi yakatwasuka patembiricha yakajairwa mumuchina wekupeta.Cold bending inokodzera mapaipi ane kunze dhayamita 17.0 kusvika 219.1 mm, uye madziro ukobvu 2.0 kusvika 28.0 mm.Iyo yakakurudzirwa kubhenda radius ndeye 2.5 x Ita.Kazhinji pakukotama radius ye40D.Nekushandisa kukotama kunotonhora, tinogona kuwana magokora madiki eradius, asi isu tinofanirwa kurongedza zvemukati nejecha kudzivirira kuunyana.Kukotama kunotonhora inzira inokurumidza uye isingadhure yekukotama.Iyo inokwikwidza sarudzo yekugadzira mapaipi uye zvikamu zvemuchina.

Welded Elbow Manufacturing process (Idiki & Hombe)

Welded elbows anogadzirwa kubva kumarata esimbi, saka haisi seamless simbi magokora.Shandisa mold uye wodzvanya ndiro yesimbi kune chimiro chegokora, wobva waisa musono kuti ive simbi yekupedzisa gokora.Ndiyo nzira yekare yekugadzira yemagokora.Makore achangopfuura masaizi madiki magokora anenge akagadzirwa kubva papombi dzesimbi izvozvi.Pamagokora mahombe, semuenzaniso, zvakaoma kugadzira magokora anopfuura 36” OD kubva papombi dzesimbi.Saka inowanzogadzirwa kubva kumarata esimbi, kudzvanya ndiro kusvika pachimiro chehafu yegokora, uye kubatanidza mahafu maviri pamwechete.Sezvo magokora akaiswa mukati memuviri wayo, kuongororwa kwejoinhi rewelding kunodiwa.Kazhinji isu tinoshandisa iyo X-Ray yekuongorora seNDT.

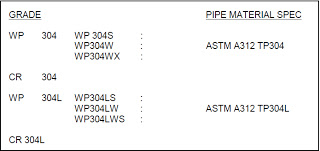

| Nominal pombi saizi | Kunze Diameter | Center to End | Center kusvika Center | Back to Faces | ||||||

| 45°Magokora | 90°Magokora | 180 ° Dzoka | ||||||||

| H | F | P | K | |||||||

| DN | INCH | Series A | Series B | LR | LR | SR | LR | SR | LR | SR |

| 15 | 1/2 | 21.3 | 18 | 16 | 38 | - | 76 | - | 48 | - |

| 20 | 3/4 | 26.9 | 25 | 16 | 38 | - | 76 | - | 51 | - |

| 25 | 1 | 33.7 | 32 | 16 | 38 | 25 | 76 | 51 | 56 | 41 |

| 32 | 11/4 | 42.4 | 38 | 20 | 48 | 32 | 95 | 64 | 70 | 52 |

| 40 | 11/2 | 48.3 | 45 | 24 | 57 | 38 | 114 | 76 | 83 | 62 |

| 50 | 2 | 60.3 | 57 | 32 | 76 | 51 | 152 | 102 | 106 | 81 |

| 65 | 21/2 | 76.1(73) | 76 | 40 | 95 | 64 | 191 | 127 | 132 | 100 |

| 80 | 3 | 88.9 | 89 | 47 | 114 | 76 | 229 | 152 | 159 | 121 |

| 90 | 31/2 | 101.6 | - | 55 | 133 | 89 | 267 | 178 | 184 | 140 |

| 100 | 4 | 114.3 | 108 | 63 | 152 | 102 | 305 | 203 | 210 | 159 |

| 125 | 5 | 139.7 | 133 | 79 | 190 | 127 | 381 | 254 | 262 | 197 |

| 150 | 6 | 168.3 | 159 | 95 | 229 | 152 | 457 | 305 | 313 | 237 |

| 200 | 8 | 219.1 | 219 | 126 | 305 | 203 | 610 | 406 | 414 | 313 |

| 250 | 10 | 273.0 | 273 | 158 | 381 | 254 | 762 | 508 | 518 | 391 |

| 300 | 12 | 323.9 | 325 | 189 | 457 | 305 | 914 | 610 | 619 | 467 |

| 350 | 14 | 355.6 | 377 | 221 | 533 | 356 | 1067 | 711 | 711 | 533 |

| 400 | 16 | 406.4 | 426 | 253 | 610 | 406 | 1219 | 813 | 813 | 610 |

| 450 | 18 | 457.2 | 478 | 284 | 686 | 457 | 1372 | 914 | 914 | 686 |

| 500 | 20 | 508.0 | 529 | 316 | 762 | 508 | 1524 | 1016 | 1016 | 762 |

| 550 | 22 | 559 | - | 347 | 838 | 559 | Cherechedza: | |||

| 600 | 24 | 610 | 630 | 379 | 914 | 610 | ||||

| 650 | 26 | 660 | - | 410 | 991 | 660 | ||||

| 700 | 28 | 711 | 720 | 442 | 1067 | 711 | ||||

| 750 | 30 | 762 | - | 473 | 1143 | 762 | ||||

| 800 | 32 | 813 | 820 | 505 | 1219 | 813 | ||||

| 850 | 34 | 864 | - | 537 | 1295 | 864 | ||||

| 900 | 36 | 914 | 920 | 568 | 1372 | 914 | ||||

| 950 | 38 | 965 | - | 600 | 1448 | 965 | ||||

| 1000 | 40 | 1016 | 1020 | 631 | 1524 | 1016 | ||||

| 1050 | 42 | 1067 | - | 663 | 1600 | 1067 | ||||

| 1100 | 44 | 1118 | 1120 | 694 | 1676 | 1118 | ||||

| 1150 | 46 | 1168 | - | 726 | 1753 | 1168 | ||||

| 1200 | 48 | 1220 | 1220 | 758 | 1829 | 1219 | ||||

ASTM A234

Iyi dhizaini inovhara yakagadzirwa kabhoni simbi & alloy simbi yekumisikidza isina musono uye welded kuvaka.Kunze kwekunge isina musono kana welded kuvaka kwatsanangurwa mukurongeka, chero inogona kupihwa pane sarudzo yemutengesi.Ese akaiswa welded ekuvaka masisitimu sekuenderana nechiyero ichi anopihwa ne100% radiography.Pasi peASTM A234, mamakisi akati wandei anowanikwa zvichienderana nekuumbwa kwemakemikari.Kusarudzwa kwaizoenderana nenyere dzepombi dzakabatana kune idzi fittings.

| Tensile Zvinodiwa | WPB | WPC, WP11CL2 | WP11CL1 | WP11CL3 |

| Kusimba Simba, min, ksi[MPa] | 60-85 | 70-95 | 60-85 | 75-100 |

| (0.2% kubvisa kana 0.5% kuwedzera-pasi-mutoro) | [415-585] | [485-655] | [415-585] | [520-690] |

| Goho Simba, min, ksi[MPa] | 32 | 40 | 30 | 45 |

| [240] | [275] | [205] | [310] |

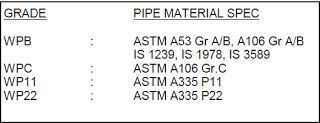

Mamwe emagiredhi anowanikwa pasi peichi chirevo uye anowirirana akabatana akabatana pombi zvinhu zvakanyorwa pazasi:

ASTM A403

Iyi dhizaini inovhara makirasi maviri akajairwa, WP & CR, yeakagadzirwa austenitic Stainless simbi yekumisikidza isina musono uye welded kuvaka.

Kirasi WP fittings inogadzirwa kune zvinodikanwa zveASME B16.9 & ASME B16.28 uye yakakamurwa kuita zvikamu zvitatu zvinotevera:

- WP - Yakagadzirwa kubva kune isina musono chigadzirwa nenzira isina musono yekugadzira.

- WP - W Izvi zvinosungirirwa zvine welds uye ese ma welds akaitwa neakakodzera mugadziri anosanganisira kutanga pombi weld kana pombi yakashongedzwa pamwe nekuwedzerwa kwezvinhu zvekuzadza zvine radiographed.Nekudaro hapana radiography inoitwa yekutanga pombi weld kana pombi yakashongedzwa pasina kuwedzera kwekuzadza zvinhu.

- WP-WX Aya mafittings ane welds uye ese maweld angave akagadzirwa nemugadziri akakodzera kana neanotanga kugadzira zvinhu ane radiographed.

Kirasi CR fittings inogadzirwa kune zvinodiwa zveMSS-SP-43 uye haidi bvunzo isingaparadze.

Pasi peASTM A403 mamakisi akati wandei anowanikwa zvichienderana nekuumbwa kwemakemikari.Kusarudzwa kwaizoenderana nenyere dzepombi dzakabatana kune idzi fittings.Mamwe emagiredhi anowanikwa pasi peichi chirevo uye anowirirana akabatana akabatana pombi zvinhu zvakanyorwa pazasi:

ASTM A420

Iyi dhizaini inovhara yakagadzirwa kabhoni simbi uye alloy simbi yekumisikidza isina musono & welded chivakwa chakagadzirirwa kushandiswa pane yakaderera tembiricha.Inobata mamakisi mana WPL6, WPL9, WPL3 & WPL8 zvichienderana nekuumbwa kwemakemikari.Zvigadziriso zveWPL6 zvinoedzwa patembiricha - 50° C, WPL9 pa -75° C, WPL3 pa -100° C uye WPL8 pa -195° C tembiricha.

Iyo inotenderwa kudzvanywa kuyerwa kwezvigadziriso inogona kuverengerwa seyakatwasuka pombi isina musono zvinoenderana nemitemo yakadzikwa muchikamu chinoshanda cheASME B31.3.

Iyo pombi madziro emadziro uye mhando yezvinhu ichave iyo iyo iyo fittings yakarairwa kuti ishandiswe, kuzivikanwa kwavo pane zvigadziriso kuri panzvimbo yekumanikidza rating mamaki.

| Simbi Nha. | Type | Kemikari yakagadzirwa | ||||||||||||

| C | Si | S | P | Mn | Cr | Ni | Mo | Zvimwe | ób | ós | δ5 | HB | ||

| WPL6 | 0.3 | 0.15-0.3 | 0.04 | 0.035 | 0.6-1.35 | 0.3 | 0.4 | 0.12 | Cb:0.02;V:0.08 | 415-585 | 240 | 22 | ||

| WPL9 | 0.2 | 0.03 | 0.03 | 0.4-1.06 | 1.6-2.24 | 435-610 | 315 | 20 | ||||||

| WPL3 | 0.2 | 0.13-0.37 | 0.05 | 0.05 | 0.31-0.64 | 3.2-3.8 | 450-620 | 240 | 22 | |||||

| WPL8 | 0.13 | 0.13-0.37 | 0.03 | 0.03 | 0.9 | 8.4-9.6 | 690-865 | 515 | 16 | |||||

Chiedza cheKuzora, Kupenda Kwemavara, Galvanizing, PE / 3PE Anti-corrosion Coating

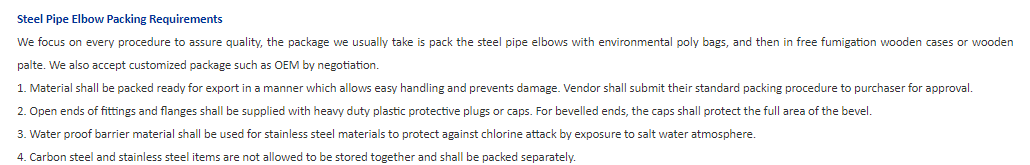

Yakarongedzwa muWood Cabins / Wood Tray