Rhannau safonau titaniwm

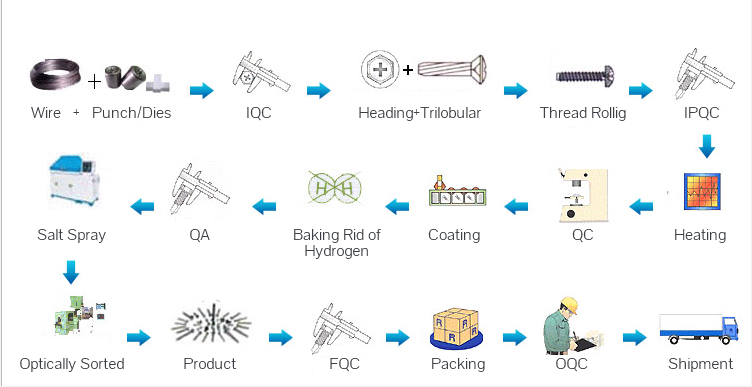

Cynhyrchu DIN, ANSI / AMSE, ISO, JIS a safonau eraill a chaewyr titaniwm cryfder uchel ansafonol.Fel arfer yn cynnwys bolltau, sgriwiau, cnau, wasieri, cylch cadw, a darnau siâp arbennig amrywiol.Yn gyntaf, byddwn yn gwneud y driniaeth wres, profi cyfansoddiad cemegol, profi priodweddau mecanyddol bariau titaniwm, platiau titaniwm a deunyddiau sylfaenol eraill.Ar ôl y broses o sythu, lefelu a sgleinio, torri i'r maint priodol.Ac yna symud ymlaen i droi, stampio poeth, sgriw cywasgu, triniaeth wres, sgleinio, glanhau, archwilio, a chyfres o weithdrefnau, yn y pen draw i gynhyrchu'r caewyr titaniwm o ansawdd uchel.Mae gennym yr offer cynhyrchu uwch a sicrhaodd ein cynnyrch i gyflawni'r gorau ym mhob cyswllt cynhyrchu.

Mae gan ein cwmni lawer o restr caewyr titaniwm, a all fodloni'r swm bach byd-eang o orchmynion a'r cwsmeriaid hynny sydd â gofyniad dosbarthu brys.Ar yr un pryd, rydym hefyd yn darparu cynhyrchion ansafonol yn ôl lluniadau a ddarperir gan gwsmeriaid.

Cais

Petroliwm, meteleg, cemegol, electronig, fferyllol, peirianneg forol, rhannau ceir, rhannau beiciau modur, rhannau beic, ategolion cychod hwylio, cyflenwadau goroesi awyr agored, nwyddau chwaraeon a meysydd eraill.

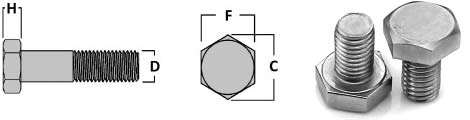

Bollt titaniwm

| Cynnyrch | Titaniwm a Titaniwm aloi bollt |

| Maint | Diamedr: M1.6-M30, Hyd: 10mm-300mm (0.39 ″-11.8 ″) |

| Deunydd | Gr.1, Gr.2, Gr.5, Gr.7 etc |

| Safonol | DIN912, DIN6912, DIN933, DIN931 ac ati |

Cnau hecs titaniwm

| Cynnyrch | Titaniwm a Titaniwm cnau aloi |

| Maint | M8-M 80 x 6 |

| Deunydd | Gr1, Gr2, Gr5, Gr7, Ti6Al4V ELI, ac ati |

| Safonol | DIN, ISO, JIS, ac ati. |

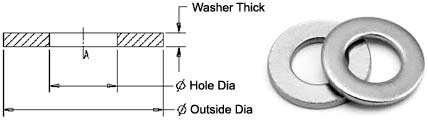

Tgolchwr itaniwm

| Cynnyrch | Titaniwm a Titaniwm golchwr aloi |

| Maint | OD: 5mm-200mm (0.20 ″-7.87″), ID: 1mm-100mm (0.04 ″-3.94″), Trwch: 0.1mm-30mm (0.004 ″-1.18 ″) |

| Deunydd | Gr.2, Gr.5 etc |

| Safonol | DIN125 ac ati |

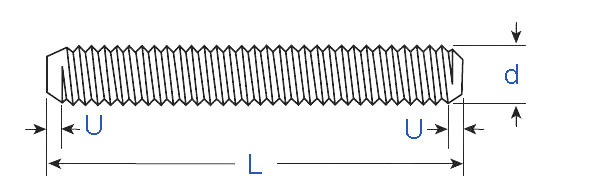

Sgriw titaniwm

| Cynnyrch | Sgriw aloi titaniwm a Titaniwm |

| Maint | M1 i M42, Hyd: 10mm-300mm (0.39 ″-11.8 ″) |

| Deunydd | Gr1, Gr.2, Gr.5, Gr.7, Gr.12 etc |

| Safonol | DIN912, DIN933, DIN84, DIN85, DIN963, DIN7991, DIN6912, DIN931, ISO7380, ac ati. |

Bridfa edafedd titaniwm

| Cynnyrch | Titaniwm a Titaniwm gre edafu aloi |

| Maint | Diamedr: M1.6-M30, Hyd: 10mm-300mm (0.39 ″-11.8 ″) |

| Deunydd | Gr.1, Gr.2, Gr.5, Gr.7, Gr.23 etc |

| Safonol | DIN912, DIN933, DIN7991, DIN7984, DIN6921, ISO 7380, JIS, BS ac ati. |

Dimensiynau Bolltau Hex Titaniwm

| Diamedr Bolt Hex Trwm | D | Dd | C | H | |||||

| Diamedr Corff | Lled Ar Draws Fflatiau | Lled Ar Draws Corneli | Uchder | ||||||

| Max | Syml | Max | Minnau | Max | Minnau | Syml | Max | Minnau | |

| 1/2 | 0.515 | 7/8 | 0.875 | 0.850 | 1.010 | 0. 969 | 11/32 | 0. 364 | 0. 302 |

| 5/8 | 0.642 | 1-1/16 | 1.062 | 1.031 | 1.227 | 1.175 | 27/64 | 0.444 | 0.378 |

| 3/4 | 0.768 | 1-1/4 | 1.250 | 1.212 | 1.443 | 1.383 | 1/2 | 0.524 | 0. 455 |

| 7/8 | 0. 895 | 1-7/16 | 1.438 | 1.394 | 1.660 | 1.589 | 37/64 | 0.604 | 0.531 |

| 1 | 1.022 | 1-5/8 | 1.625 | 1.575 | 1.876 | 1.796 | 43/64 | 0.700 | 0. 591 |

| 1-1/8 | 1.149 | 1-13/16 | 1.812 | 1.756 | 2. 093 | 2.002 | 3/4 | 0.780 | 0.658 |

| 1-1/4 | 1.277 | 2 | 2.00 | 1.938 | 2. 309 | 2. 209 | 27/32 | 0.876 | 0. 749 |

| 1-3/8 | 1.404 | 2-3/16 | 2. 188 | 2. 119 | 2.526 | 2. 416 | 29/32 | 0. 940 | 0. 810 |

| 1-1/2 | 1.531 | 2-3/8 | 2.375 | 2.300 | 2.742 | 2.622 | 1 | 1.036 | 0. 902 |

| 1-3/4 | 1.785 | 2-3/4 | 2.750 | 2.662 | 3. 175 | 3.035 | 1-5/32 | 1. 196 | 1.054 |

| 2 | 2. 039 | 3-1/8 | 3. 125 | 3.025 | 3.608 | 3.449 | 1-11/32 | 1.388 | 1.175 |

| 2-1/4 | 2. 305 | 3-1/2 | 3.500 | 3.388 | 4.041 | 3.862 | 1-1/2 | 1.548 | 1.327 |

| 2-1/2 | 2.559 | 3-7/8 | 3.875 | 3.750 | 4.474 | 4.275 | 1-21/32 | 1.708 | 1.479 |

Dimensiynau Cnau Hecs

| Cnau Hecs Titaniwm ISO DS | Ar Draws Corneli | Trwch MAX | MIN Trwch | MAX Ar Draws Fflatiau | MIN Ar Draws Fflatiau |

| M 8 | 14.38 | 6.8 | 6.44 | 13 | 12.73 |

| M 10 | 17.77 | 8.4 | 8.04 | 16 | 15.73 |

| M 12 | 20.03 | 10.8 | 10.37 | 18 | 17.73 |

| M 14 | 23.35 | 12.8 | 12.1 | 21 | 20.67 |

| M 16 | 26.75 | 14.8 | 14.1 | 24 | 23.67 |

| M 18 | 29.56 | 15.8 | 15.1 | 27 | 26.16 |

| M 20 | 32.95 | 18 | 16.9 | 30 | 29.16 |

| M 22 | 37.29 | 19.4 | 18.1 | 34 | 33 |

| M 24 | 39.55 | 21.5 | 20.2 | 36 | 35 |

| M 27 | 45.2 | 23.8 | 22.5 | 41 | 40 |

| M 30 | 50.85 | 26.6 | 24.3 | 46 | 45 |

| M 33 | 55.37 | 28.7 | 27.4 | 50 | 49 |

| M 36 | 60.79 | 31 | 29.4 | 55 | 53.8 |

| M 39 | 66.44 | 33.4 | 31.8 | 60 | 58.8 |

| M 42 | 71.3 | 34 | 32.4 | 65 | 63.1 |

| M 45 | 76.95 | 36 | 34.4 | 70 | 68.1 |

| M 48 | 82.6 | 38 | 39.4 | 75 | 73.1 |

| M 52 | 88.25 | 42 | 40.4 | 80 | 78.1 |

| M 56 | 93.56 | 45 | 43.4 | 85 | 82.8 |

| M 60 | 99.21 | 48 | 46.4 | 90 | 87.8 |

| M 64 | 104.86 | 51 | 49.1 | 95 | 92.8 |

| M 68 | 110.51 | 54 | 52.1 | 100 | 97.8 |

| M 72 x 6 | 116.16 | 58 | 56.1 | 105 | 102.8 |

| M 76 x 6 | 121.81 | 61 | 59.1 | 110 | 107.8 |

| M 80 x 6 | 127.46 | 64 | 62.1 | 115 | 112.8 |

Dimensiynau golchwr fflat titaniwm

| Ti Maint Bollt Alloy | USS | SAE | ||||

| OD (yn.) | ID (yn.) | Trwch | OD (yn.) | ID (yn.) | Trwch | |

| 1/8 (#6) | - | - | - | 0. 375 | 0. 156 | .036/.065 |

| 5/32 (#8) | - | - | - | 0. 438 | 0. 188 | .036/.065 |

| 3/16 (#10) | 0.560 | 0.250 | .036/.065 | 0.500 | 0.220 | .036/.065 |

| 7/32 (#12) | - | - | - | 0. 562 | 0.250 | .051/.080 |

| 1/4 (#14) | 0.734 | 0. 312 | .051/.080 | 0.625 | 0.281 | .051/.080 |

| 5/16 | 0.875 | 0. 375 | .064/.104 | 0.688 | 0. 344 | .051/.080 |

| 3/8 | 1.000 | 0. 438 | .064/.104 | 0.812 | 0. 406 | .051/.080 |

| 7/16 | 1.250 | 0.500 | .064/.104 | 0.922 | 0.469 | .051/.080 |

| 1/2 | 1.375 | 0. 562 | .086/.132 | 1.062 | 0.531 | .074/.121 |

| 9/16 | 1.469 | 0.625 | .086/.132 | 1. 156 | 0. 594 | .074/.121 |

| 5/8 | 1.750 | 0.688 | .108/.160 | 1.312 | 0.656 | .074/.121 |

| 3/4 | 2.000 | 0.812 | .122/.177 | 1.469 | 0.812 | .108/.160 |

| 7/8 | 2.250 | 0. 938 | .136/.192 | 1.750 | 0. 938 | .108/.160 |

| 1 | 2.500 | 1.062 | .136/.192 | 2.000 | 1.062 | .108/.160 |

| 1 1/8 | 2.750 | 1.250 | .136/.192 | 2.250 | 1.250 | .108/.160 |

| 1 1/4 | 3.000 | 1.375 | .136/.192 | 2.500 | 1.375 | .136/.192 |

| 1 3/8 | 3. 250 | 1.500 | .153/.213 | 2.750 | 1.500 | .136/.213 |

| 1 1/2 | 3.500 | 1.625 | .153/.213 | 3.000 | 1.625 | .153/.213 |

| 1 5/8 | 3.750 | 1.750 | .153/.213 | - | - | - |

| 1 3/4 | 4.000 | 1.875 | .153/.213 | - | - | - |

| 1 7/8 | 4.250 | 2.000 | .153/.213 | - | - | - |

| 2 | 4.500 | 2. 125 | .153/.213 | - | - | - |

| 2 1/4 | 4.750 | 2.375 | .193/.248 | - | - | - |

| 2 1/2 | 5.000 | 2.625 | .210/.280 | - | - | - |

| 2 3/4 | 5.250 | 2.875 | .228/.310 | - | - | - |

| 3 | 5.500 | 3. 125 | .249/.327 | - | - | - |

Dimensiynau Sgriw Cap Pen Soced

| Ti Alloy Sgriw Nom.Maint Cae Thread | Corff | Pen | Pen | Chamfer | Hecsagon | Spline | Allwedd | Pontio | |||

| Max | Minnau | Max | Minnau | Max | Minnau | Max | Nom. | Nom. | Minnau | Max | |

| M1.6 × 0.35 | 1.60 | 1.46 | 3.00 | 2.87 | 1.60 | 1.52 | 0.16 | 1.5 | 1.829 | 0.80 | 2.0 |

| M2 × 0.4 | 2.00 | 1.86 | 3.80 | 3.65 | 2.00 | 1.91 | 0.20 | 1.5 | 1.829 | 1.00 | 2.6 |

| M2.5 × 0.45 | 2.50 | 2.36 | 4.50 | 4.33 | 2.50 | 2.40 | 0.25 | 2.0 | 2.438 | 1.25 | 3.1 |

| M3 × 0.5 | 3.00 | 2.86 | 5.50 | 5.32 | 3.00 | 2.89 | 0.30 | 2.5 | 2.819 | 1.50 | 3.6 |

| M4 × 0.7 | 4.00 | 3.82 | 7.00 | 6.80 | 4.00 | 3.88 | 0.40 | 3.0 | 3.378 | 2.00 | 4.7 |

| M5 × 0.8 | 5.00 | 4.82 | 8.50 | 8.27 | 5.00 | 4.86 | 0.50 | 4.0 | 4.648 | 2.50 | 5.7 |

| M6 × 1 | 6.00 | 5.82 | 10.00 | 9.74 | 6.00 | 5.85 | 0.60 | 5.0 | 5.486 | 3.00 | 6.8 |

| M8 × 1.25 | 8.00 | 7.78 | 13.00 | 12.70 | 8.00 | 7.83 | 0.80 | 6.0 | 7.391 | 4.00 | 9.2 |

| M10 × 1.5 | 10.00 | 9.78 | 16.00 | 15.67 | 10.00 | 9.81 | 1.00 | 8.0 | … | 5.00 | 11.2 |

| M12 × 1.75 | 12.00 | 11.73 | 18.00 | 17.63 | 12.00 | 11.79 | 1.20 | 10.0 | … | 6.00 | 14.2 |

| M14 × 2b | 14.00 | 13.73 | 21.00 | 20.60 | 14.00 | 13.77 | 1.40 | 12.0 | … | 7.00 | 16.2 |

| M16 × 2 | 16.00 | 15.73 | 24.00 | 23.58 | 16.00 | 15.76 | 1.60 | 14.0 | … | 8.00 | 18.2 |

| M20 × 2.5 | 20.00 | 19.67 | 30.00 | 29.53 | 20.00 | 19.73 | 2.00 | 17.0 | … | 10.00 | 22.4 |

| M24 × 3 | 24.00 | 23.67 | 36.00 | 35.48 | 24.00 | 23.70 | 2.40 | 19.0 | … | 12.00 | 26.4 |

| M30 × 3.5 | 30.00 | 29.67 | 45.00 | 44.42 | 30.00 | 29.67 | 3.00 | 22.0 | … | 15.00 | 33.4 |

| M36 × 4 | 36.00 | 35.61 | 54.00 | 53.37 | 36.00 | 35.64 | 3.60 | 27.0 | … | 18.00 | 39.4 |

| M42 × 4.5 | 42.00 | 41.61 | 63.00 | 62.31 | 42.00 | 41.61 | 4.20 | 32.0 | … | 21.00 | 45.6 |

| M48 × 5 | 48.00 | 47.61 | 72.00 | 71.27 | 48.00 | 47.58 | 4.80 | 36.0 | … | 24.00 | |

Bridfa edafedd titaniwm

| ANSI /ASMEB 18.31.2 Uned Rodiau Edau: modfedd | ||||

| d | traw | |||

| UNC | UNF | 8UN | ||

| 1/4 | 0.25 | 20 | 28 | / |

| 5/16 | 0. 3125 | 18 | 24 | / |

| 3/8 | 0. 375 | 18 | 24 | / |

| 7/16 | 0. 4375 | 14 | 20 | / |

| 1/2 | 0.5 | 13 | 20 | / |

| 9/16 | 0. 5625 | 12 | 18 | / |

| 5/8 | 0.625 | 11 | 18 | / |

| 3/4 | 0.75 | 10 | 16 | / |

| 7/8 | 0.875 | 9 | 14 | / |

| 1 | 1 | 8 | 12 | 8 |

| 1-1/8 | 1.125 | 7 | 12 | 8 |

| 1-1/4 | 1.25 | 7 | 12 | 8 |

| 1-3/8 | 1.375 | 6 | 12 | 8 |

| Uned: modfedd | ||||

| d | traw | |||

| UNC | UNF | 8UN | ||

| 1-1/2 | 1.5 | 6 | 12 | 8 |

| 1-5/8 | 1.625 | / | / | 8 |

| 1-3/7 | 1.75 | 5 | / | 8 |

| 1-7/8 | 1.875 | / | / | 8 |

| 2 | 2 | 4-1/2 | / | 8 |

| 2-1/4 | 2.25 | 4-1/2 | / | 8 |

| 2-1/2 | 2.5 | 4 | / | 8 |

| 2-3/4 | 2.75 | 4 | / | 8 |

| 3 | 3 | 4 | / | 8 |

| 3-1/4 | 3.25 | 4 | / | 8 |

| 3-1/2 | 3.5 | 4 | / | 8 |

| 3-3/4 | 3.75 | 4 | / | 8 |

| 4 | 4 | 4 | / | 8 |

| L | 1/2 <L≤2-1/2 | 2-1/2 <L≤4 | 4<L≤8 | 8<L≤16 | 16<L |

| Goddefgarwch hyd gre wedi'i gau | ±0.04 | ±0.08 | ±0.10 | ±0.12 | ±0.18 |

| Safonol | Disgrifiad | Safonol | Disgrifiad |

| DIN 84 | Sgriwiau pen caws slotiedig | DIN 439 | Cnau jam |

| DIN 125 | Wasieri fflat | DIN 963 | Sgriwiau pen fflat wedi'u toddi â slot |

| DIN 127 | Golchwyr clo gwanwyn | DIN 965 | Phillips sgriwiau peiriant pen fflat |

| DIN 912 | Sgriwiau cap pen soced hecs | DIN 985 | Cloi cnau (gyda mewnosodiad anfetelaidd) |

| DIN913/DIN 914/DIN915/DIN916 | Gosod sgriwiau | DIN 1665/DIN 6921 | Bolltau hecs gyda fflans |

| DIN 931 | Sgriwiau cap pen hecs (edau rhan) | DIN 6912/DIN 7984 | Sgriwiau cap pen tenau soced hecsagon |

| DIN 933 | Sgriwiau cap pen hecs (edau llawn) | DIN 7991 | Sgriwiau cap soced soced cownter fflat |

| DIN 934 | Cnau hecs | DIN 9021 | Golchwr fflat |

Graddau Cyfwerth â Deunydd Ar gyfer Caewyr Titaniwm

| SAFON | WERKSTOFF NR. | UNS |

| Titaniwm Gradd 2 | 3. 7035 | R50400 |

| Titaniwm Gradd 5 | 3. 7165 | R56400 |

Nodweddion Mecanyddol Caewyr Titaniwm

| Gradd | Cryfder tynnol (min) | Cryfder Cynnyrch 0.2% Gwrthbwyso | Elongation mewn 2 fodfedd neu 50mm % (min) | ||

| KSI | MPa | KSI | MPa | ||

| Gr.1 | 35 | 240 | 20-45 | 138-310 | 24 |

| Gr.2 | 50 | 345 | 40-65 | 275 – 450 | 20 |

| Gr.3 | 65 | 450 | 55-80 | 380 – 550 | 18 |

| Gr.4 | 80 | 550 | ≥70 | ≥483 | 15 |

| Gr.5 | 138 | 950 | ≥128 | ≥880 | 14 |

| Gr.7 | 50 | 345 | ≥40 | ≥275 | 24 |

| Gr.9 | 125 | 860 | ≥105 | ≥725 | 10 |

| Gr.12 | 70 | 483 | ≥50 | ≥345 | 18 |

| Gr.23 | 125 | 860 | ≥115 | ≥790 | 15 |

| Elfen | Dwysedd | Ymdoddbwynt | Cryfder Tynnol | Cryfder Cynnyrch (Gwrthbwyso 0.2%) | Elongation |

| Titaniwm Gr.2 | 4.5 g/cm3 | 1665 °C (3030 °F) | Psi – 49900 , MPa – 344 | Psi – 39900 , MPa – 275 | 20 % |

| Titaniwm Gr.5 | 4.43 g/cm3 | 1632 °C (2970 °F) | Psi – 138000, MPa – 950 | Psi – 128000, MPa – 880 | 14 % |

Cyfansoddiad Deunydd Cemegol Caewyr Titaniwm

| Gradd | Fe% | C% | N% | H% | O% | Al % | V% | Mo% | Ni% | Pd% | Ti |

| Gr1 | 0.2 | 0.08 | 0.03 | 0.015 | 0.18 | - | - | - | - | - | BAL. |

| Gr2 | 0.3 | 0.08 | 0.03 | 0.015 | 0.25 | - | - | - | - | - | BAL. |

| Gr3 | 0.3 | 0.08 | 0.05 | 0.015 | 0.35 | - | - | - | - | - | BAL. |

| Gr4 | 0.3 | 0.08 | 0.05 | 0.015 | 0.40 | - | - | - | - | - | BAL |

| Gr5 | 0.25 | 0.08 | 0.03 | 0.015 | 0.02 | 5.5 – 6.75 | 3.5 – 4.5 | - | - | - | BAL |

| Gr7 | 0.3 | 0.08 | 0.03 | 0.015 | 0.25 | - | - | - | - | 0.12 – 0.25 | BAL. |

| Gr9 | 0.25 | 0.08 | 0.03 | 0.015 | 0.15 | 2.5 – 3.3 | 2.0 – 3.0 | - | - | - | BAL. |

| Gr12 | 0.3 | 0.08 | 0.03 | 0.015 | 0.25 | - | - | 0.2 – 0.4 | 0.6 – 0.9 | - | BAL. |

| Gr23 | 0.3 | 0.08 | 0.03 | 0.015 | 0.13 | 5.5 – 6.75 | - | - | - | - | B |