Titanium zviyero zvikamu

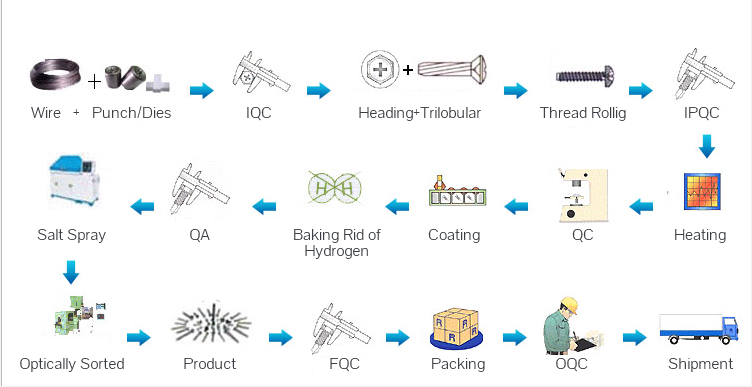

Kugadzirwa kweDIN, ANSI / AMSE, ISO, JIS uye mamwe maitiro uye zvisiri-standard high-simba titanium fasteners.Kazhinji anosanganisira mabhaudhi, screws, nzungu, washers, retaining ring, uye akasiyana-siyana-akakosha zvidimbu.Chekutanga, isu tichaita kupisa kwekupisa, kuyerwa kwemakemikari ekuumbwa, kuyedza zvivakwa zvetitanium mabara, titanium mahwendefa uye zvimwe zvakakosha zvinhu.Mushure mekugadzirisa kururamisa, kuenzanisa uye kupenya, cheka muhukuru hwakakodzera.Uye woenderera mberi nekutendeuka, kupisa stamping, compression screw, kupisa kupisa, kupukuta, kuchenesa, kuongorora, uye nhevedzano yemaitiro, pakupedzisira kuburitsa emhando yepamusoro titanium fasteners.Tine michina yekugadzira yepamusoro iyo yakaona kuti zvigadzirwa zvedu zviwane zvakanakisa mune yega yega link yekugadzira.

Kambani yedu ine yakawanda yetitanium fasteners inventory, iyo inogona kugutsa huwandu hwepasi rose hwemaodha uye avo vatengi vane kukurumidza kuendesa zvinodiwa.Panguva imwecheteyo, isu tinopawo zvisiri-yakajairwa zvigadzirwa zvinoenderana nemifananidzo yakapihwa nevatengi.

Application

Petroleum, simbi, makemikari, zvemagetsi, mishonga, Marine engineering, auto zvikamu, midhudhudhu, zvikamu zvebhasikoro, yacht accessories, zvekunze zvekupona, zvinhu zvemitambo nezvimwe minda.

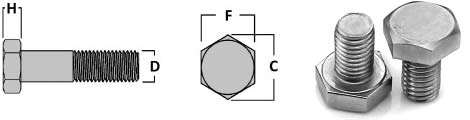

Titanium bolt

| Product | Titanium uye Titanium alloy bolt |

| Size | Dhayamita: M1.6-M30, Kureba: 10mm-300mm (0.39″-11.8″) |

| Material | Gr.1, Gr.2, Gr.5, Gr.7 zvichingodaro |

| Standard | DIN912, DIN6912, DIN933, DIN931 nezvimwe |

Titanium hex nut

| Product | Titanium uye Titanium alloy nut |

| Size | M8-M 80 x 6 |

| Material | Gr1, Gr2, Gr5, Gr7, Ti6Al4V ELI, zvichingodaro |

| Standard | DIN, ISO, JIS, nezvimwe. |

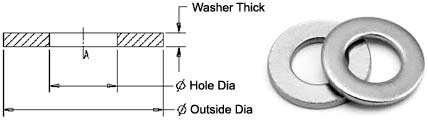

Titanium washer

| Product | Titanium uye Titanium alloy washer |

| Size | OD: 5mm-200mm (0.20″-7.87″), ID: 1mm-100mm (0.04″-3.94″), Ukobvu: 0.1mm-30mm (0.004″-1.18″) |

| Material | Gr.2, Gr.5 zvichingodaro |

| Standard | DIN125 nezvimwe |

Titanium screw

| Product | Titanium uye Titanium alloy screw |

| Size | M1 kusvika M42, Kureba: 10mm-300mm (0.39″-11.8″) |

| Material | Gr1, Gr.2, Gr.5, Gr.7, Gr.12 zvichingodaro |

| Standard | DIN912, DIN933, DIN84, DIN85, DIN963, DIN7991, DIN6912, DIN931, ISO7380, etc. |

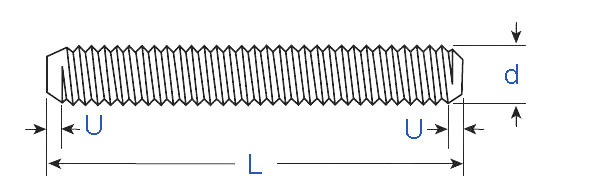

Titanium threaded stud

| Product | Titanium neTitanium alloy threaded stud |

| Size | Dhayamita: M1.6-M30, Kureba: 10mm-300mm (0.39″-11.8″) |

| Material | Gr.1, Gr.2, Gr.5, Gr.7, Gr.23 zvichingodaro |

| Standard | DIN912, DIN933, DIN7991, DIN7984, DIN6921, ISO 7380, JIS, BS nezvimwe. |

Titanium Hex Bolts Dimensions

| Heavy Bolt Diameter | D | F | C | H | |||||

| Body Diameter | Upamhi Mhiri Mafurati | Upamhi Mhiri Kwemakona | Urefu | ||||||

| Max | Basic | Max | Min | Max | Min | Basic | Max | Min | |

| 1/2 | 0.515 | 7/8 | 0.875 | 0.850 | 1.010 | 0.969 | 11/32 | 0.364 | 0.302 |

| 5/8 | 0.642 | 1-1/16 | 1.062 | 1.031 | 1.227 | 1.175 | 27/64 | 0.444 | 0.378 |

| 3/4 | 0.768 | 1-1/4 | 1.250 | 1.212 | 1.443 | 1.383 | 1/2 | 0.524 | 0.455 |

| 7/8 | 0.895 | 1-7/16 | 1.438 | 1.394 | 1.660 | 1.589 | 37/64 | 0.604 | 0.531 |

| 1 | 1.022 | 1-5/8 | 1.625 | 1.575 | 1.876 | 1.796 | 43/64 | 0.700 | 0.591 |

| 1-1/8 | 1.149 | 1-13/16 | 1.812 | 1.756 | 2.093 | 2.002 | 3/4 | 0.780 | 0.658 |

| 1-1/4 | 1.277 | 2 | 2.00 | 1.938 | 2.309 | 2.209 | 27/32 | 0.876 | 0.749 |

| 1-3/8 | 1.404 | 2-3/16 | 2.188 | 2.119 | 2.526 | 2.416 | 29/32 | 0.940 | 0.810 |

| 1-1/2 | 1.531 | 2-3/8 | 2.375 | 2.300 | 2.742 | 2.622 | 1 | 1.036 | 0.902 |

| 1-3/4 | 1.785 | 2-3/4 | 2.750 | 2.662 | 3.175 | 3.035 | 1-5/32 | 1.196 | 1.054 |

| 2 | 2.039 | 3-1/8 | 3.125 | 3.025 | 3.608 | 3.449 | 1-11/32 | 1.388 | 1.175 |

| 2-1/4 | 2.305 | 3-1/2 | 3.500 | 3.388 | 4.041 | 3.862 | 1-1/2 | 1.548 | 1.327 |

| 2-1/2 | 2.559 | 3-7/8 | 3.875 | 3.750 | 4.474 | 4.275 | 1-21/32 | 1.708 | 1.479 |

Hex Nuts Dimensions

| ISO Titanium Hex Nut NB | Mhiri Kwemakona | MAX Ukobvu | MIN Ukobvu | MAX Across Flats | MIN Across Flats |

| M8 | 14.38 | 6.8 | 6.44 | 13 | 12.73 |

| M10 | 17.77 | 8.4 | 8.04 | 16 | 15.73 |

| M12 | 20.03 | 10.8 | 10.37 | 18 | 17.73 |

| M14 | 23.35 | 12.8 | 12.1 | 21 | 20.67 |

| M16 | 26.75 | 14.8 | 14.1 | 24 | 23.67 |

| M 18 | 29.56 | 15.8 | 15.1 | 27 | 26.16 |

| M20 | 32.95 | 18 | 16.9 | 30 | 29.16 |

| M 22 | 37.29 | 19.4 | 18.1 | 34 | 33 |

| M 24 | 39.55 | 21.5 | 20.2 | 36 | 35 |

| M 27 | 45.2 | 23.8 | 22.5 | 41 | 40 |

| M30 | 50.85 | 26.6 | 24.3 | 46 | 45 |

| M 33 | 55.37 | 28.7 | 27.4 | 50 | 49 |

| M 36 | 60.79 | 31 | 29.4 | 55 | 53.8 |

| M 39 | 66.44 | 33.4 | 31.8 | 60 | 58.8 |

| M42 | 71.3 | 34 | 32.4 | 65 | 63.1 |

| M45 | 76.95 | 36 | 34.4 | 70 | 68.1 |

| M 48 | 82.6 | 38 | 39.4 | 75 | 73.1 |

| M52 | 88.25 | 42 | 40.4 | 80 | 78.1 |

| M56 | 93.56 | 45 | 43.4 | 85 | 82.8 |

| M60 | 99.21 | 48 | 46.4 | 90 | 87.8 |

| M 64 | 104.86 | 51 | 49.1 | 95 | 92.8 |

| M 68 | 110.51 | 54 | 52.1 | 100 | 97.8 |

| M 72 x 6 | 116.16 | 58 | 56.1 | 105 | 102.8 |

| M 76 x 6 | 121.81 | 61 | 59.1 | 110 | 107.8 |

| M80 x 6 | 127.46 | 64 | 62.1 | 115 | 112.8 |

Titanium Flat Washer Dimensions

| Ti Alloy Bolt Size | USS | SAE | ||||

| OD (mu.) | ID (in.) | Ukobvu | OD (mu.) | ID (in.) | Ukobvu | |

| 1/8 (#6) | - | - | - | 0.375 | 0.156 | .036/.065 |

| 5/32 (#8) | - | - | - | 0.438 | 0.188 | .036/.065 |

| 3/16 (#10) | 0.560 | 0.250 | .036/.065 | 0.500 | 0.220 | .036/.065 |

| 7/32 (#12) | - | - | - | 0.562 | 0.250 | .051/.080 |

| 1/4 (#14) | 0.734 | 0.312 | .051/.080 | 0.625 | 0.281 | .051/.080 |

| 5/16 | 0.875 | 0.375 | .064/.104 | 0.688 | 0.344 | .051/.080 |

| 3/8 | 1.000 | 0.438 | .064/.104 | 0.812 | 0.406 | .051/.080 |

| 7/16 | 1.250 | 0.500 | .064/.104 | 0.922 | 0.469 | .051/.080 |

| 1/2 | 1.375 | 0.562 | .086/.132 | 1.062 | 0.531 | .074/.121 |

| 9/16 | 1.469 | 0.625 | .086/.132 | 1.156 | 0.594 | .074/.121 |

| 5/8 | 1.750 | 0.688 | .108/.160 | 1.312 | 0.656 | .074/.121 |

| 3/4 | 2.000 | 0.812 | .122/.177 | 1.469 | 0.812 | .108/.160 |

| 7/8 | 2.250 | 0.938 | .136/.192 | 1.750 | 0.938 | .108/.160 |

| 1 | 2.500 | 1.062 | .136/.192 | 2.000 | 1.062 | .108/.160 |

| 1 1/8 | 2.750 | 1.250 | .136/.192 | 2.250 | 1.250 | .108/.160 |

| 1 1/4 | 3.000 | 1.375 | .136/.192 | 2.500 | 1.375 | .136/.192 |

| 1 3/8 | 3.250 | 1.500 | .153/.213 | 2.750 | 1.500 | .136/.213 |

| 1 1/2 | 3.500 | 1.625 | .153/.213 | 3.000 | 1.625 | .153/.213 |

| 1 5/8 | 3.750 | 1.750 | .153/.213 | - | - | - |

| 1 3/4 | 4.000 | 1.875 | .153/.213 | - | - | - |

| 1 7/8 | 4.250 | 2.000 | .153/.213 | - | - | - |

| 2 | 4.500 | 2.125 | .153/.213 | - | - | - |

| 2 1/4 | 4.750 | 2.375 | .193/.248 | - | - | - |

| 2 1/2 | 5.000 | 2.625 | .210/.280 | - | - | - |

| 2 3/4 | 5.250 | 2.875 | .228/.310 | - | - | - |

| 3 | 5.500 | 3.125 | .249/.327 | - | - | - |

Socket Head Cap Screw Dimensions

| Ti Alloy Screw Nom.Size Thread Pitch | Muviri | Musoro | Musoro | Chamfer | Hexagon | Spline | Key | Transition | |||

| Max | Min | Max | Min | Max | Min | Max | Nom. | Nom. | Min | Max | |

| M1.6 × 0.35 | 1.60 | 1.46 | 3.00 | 2.87 | 1.60 | 1.52 | 0.16 | 1.5 | 1.829 | 0.80 | 2.0 |

| M2 × 0.4 | 2.00 | 1.86 | 3.80 | 3.65 | 2.00 | 1.91 | 0.20 | 1.5 | 1.829 | 1.00 | 2.6 |

| M2.5 × 0.45 | 2.50 | 2.36 | 4.50 | 4.33 | 2.50 | 2.40 | 0.25 | 2.0 | 2.438 | 1.25 | 3.1 |

| M3 × 0.5 | 3.00 | 2.86 | 5.50 | 5.32 | 3.00 | 2.89 | 0.30 | 2.5 | 2.819 | 1.50 | 3.6 |

| M4 × 0.7 | 4.00 | 3.82 | 7.00 | 6.80 | 4.00 | 3.88 | 0.40 | 3.0 | 3.378 | 2.00 | 4.7 |

| M5 × 0.8 | 5.00 | 4.82 | 8.50 | 8.27 | 5.00 | 4.86 | 0.50 | 4.0 | 4.648 | 2.50 | 5.7 |

| M6 × 1 | 6.00 | 5.82 | 10.00 | 9.74 | 6.00 | 5.85 | 0.60 | 5.0 | 5.486 | 3.00 | 6.8 |

| M8 × 1.25 | 8.00 | 7.78 | 13.00 | 12.70 | 8.00 | 7.83 | 0.80 | 6.0 | 7.391 | 4.00 | 9.2 |

| M10 × 1.5 | 10.00 | 9.78 | 16.00 | 15.67 | 10.00 | 9.81 | 1.00 | 8.0 | … | 5.00 | 11.2 |

| M12 × 1.75 | 12.00 | 11.73 | 18.00 | 17.63 | 12.00 | 11.79 | 1.20 | 10.0 | … | 6.00 | 14.2 |

| M14 × 2b | 14.00 | 13.73 | 21.00 | 20.60 | 14.00 | 13.77 | 1.40 | 12.0 | … | 7.00 | 16.2 |

| M16 × 2 | 16.00 | 15.73 | 24.00 | 23.58 | 16.00 | 15.76 | 1.60 | 14.0 | … | 8.00 | 18.2 |

| M20 × 2.5 | 20.00 | 19.67 | 30.00 | 29.53 | 20.00 | 19.73 | 2.00 | 17.0 | … | 10.00 | 22.4 |

| M24 × 3 | 24.00 | 23.67 | 36.00 | 35.48 | 24.00 | 23.70 | 2.40 | 19.0 | … | 12.00 | 26.4 |

| M30 × 3.5 | 30.00 | 29.67 | 45.00 | 44.42 | 30.00 | 29.67 | 3.00 | 22.0 | … | 15.00 | 33.4 |

| M36 × 4 | 36.00 | 35.61 | 54.00 | 53.37 | 36.00 | 35.64 | 3.60 | 27.0 | … | 18.00 | 39.4 |

| M42 × 4.5 | 42.00 | 41.61 | 63.00 | 62.31 | 42.00 | 41.61 | 4.20 | 32.0 | … | 21.00 | 45.6 |

| M48 × 5 | 48.00 | 47.61 | 72.00 | 71.27 | 48.00 | 47.58 | 4.80 | 36.0 | … | 24.00 | |

Titanium threaded stud

| ANSI /ASMEB 18.31.2 Threaded Rods-Unit:inch | ||||

| d | pitch | |||

| UNC | UNF | 8UN | ||

| 1/4 | 0.25 | 20 | 28 | / |

| 5/16 | 0.3125 | 18 | 24 | / |

| 3/8 | 0.375 | 18 | 24 | / |

| 7/16 | 0.4375 | 14 | 20 | / |

| 1/2 | 0.5 | 13 | 20 | / |

| 9/16 | 0.5625 | 12 | 18 | / |

| 5/8 | 0.625 | 11 | 18 | / |

| 3/4 | 0.75 | 10 | 16 | / |

| 7/8 | 0.875 | 9 | 14 | / |

| 1 | 1 | 8 | 12 | 8 |

| 1-1/8 | 1.125 | 7 | 12 | 8 |

| 1-1/4 | 1.25 | 7 | 12 | 8 |

| 1-3/8 | 1.375 | 6 | 12 | 8 |

| Chiyero:inch | ||||

| d | pitch | |||

| UNC | UNF | 8UN | ||

| 1-1/2 | 1.5 | 6 | 12 | 8 |

| 1-5/8 | 1.625 | / | / | 8 |

| 1-3/7 | 1.75 | 5 | / | 8 |

| 1-7/8 | 1.875 | / | / | 8 |

| 2 | 2 | 4-1/2 | / | 8 |

| 2-1/4 | 2.25 | 4-1/2 | / | 8 |

| 2-1/2 | 2.5 | 4 | / | 8 |

| 2-3/4 | 2.75 | 4 | / | 8 |

| 3 | 3 | 4 | / | 8 |

| 3-1/4 | 3.25 | 4 | / | 8 |

| 3-1/2 | 3.5 | 4 | / | 8 |

| 3-3/4 | 3.75 | 4 | / | 8 |

| 4 | 4 | 4 | / | 8 |

| L | 1/2<L≤2-1/2 | 2-1/2<L≤4 | 4<L≤8 | 8<L≤16 | 16<L |

| Yakasimbiswa stud kureba kushivirira | ±0.04 | ±0.08 | ±0.10 | ±0.12 | ±0.18 |

| Standard | Tsanangudzo | Standard | Tsanangudzo |

| DIN 84 | Slotted cheese musoro screws | DIN 439 | Jam nuts |

| DIN 125 | Flat washers | DIN 963 | Slotted countersunk flat head screws |

| DIN 127 | Spring lock washers | DIN 965 | Phillips flat musoro muchina screws |

| DIN 912 | Hex socket head cap screws | DIN 985 | Kiya nzungu (ine isiri-simbi inopinza) |

| DIN913/DIN 914/DIN915/DIN916 | Seta screws | DIN 1665/DIN 6921 | Hex mabhoti ane flange |

| DIN 931 | Hex musoro cap screws (chikamu shinda) | DIN 6912/DIN 7984 | Hexagon socket yakatetepa musoro cap screws |

| DIN 933 | Hex musoro cap screws (yakazara shinda) | DIN 7991 | Flat head countersunk socket cap screws |

| DIN 934 | Hex nzungu | DIN 9021 | Flat washer |

Material Yakaenzana Magiredhi ETitanium Fasteners

| STANDARD | WERKSTOFF NR. | UNS |

| Titanium Grade2 | 3.7035 | R50400 |

| Titanium Grade5 | 3.7165 | R56400 |

Mechanical Hunhu hweTitanium Fasteners

| Giredhi | Kusimba Simba (min) | Goho Simba 0.2% Offset | Elongation mu 2 inch kana 50mm % (min) | ||

| KSI | MPa | KSI | MPa | ||

| Gr.1 | 35 | 240 | 20-45 | 138 – 310 | 24 |

| Gr.2 | 50 | 345 | 40 - 65 | 275 - 450 | 20 |

| Gr.3 | 65 | 450 | 55 - 80 | 380 - 550 | 18 |

| Gr.4 | 80 | 550 | ≥70 | ≥483 | 15 |

| Gr.5 | 138 | 950 | ≥128 | ≥880 | 14 |

| Gr.7 | 50 | 345 | ≥40 | ≥275 | 24 |

| Gr.9 | 125 | 860 | ≥105 | ≥725 | 10 |

| Gr.12 | 70 | 483 | ≥50 | ≥345 | 18 |

| Gr.23 | 125 | 860 | ≥115 | ≥790 | 15 |

| Element | Density | Melting Point | Tensile Simba | Goho Simba (0.2% Offset) | Elongation |

| Titanium Gr.2 | 4.5 g/cm3 | 1665 °C (3030 °F) | Psi – 49900 , MPa – 344 | Psi – 39900 , MPa – 275 | 20 % |

| Titanium Gr.5 | 4.43 g/cm3 | 1632 °C (2970 °F) | Psi - 138000 , MPa - 950 | Psi - 128000 , MPa - 880 | 14 % |

Kemikari Material Kuumbwa kweTitanium Fasteners

| Giredhi | Fe% | C% | N% | H% | O% | Al% | V% | Mo% | Ni% | Pd% | Ti |

| Gr1 | 0.2 | 0.08 | 0.03 | 0.015 | 0.18 | - | - | - | - | - | BAL. |

| Gr2 | 0.3 | 0.08 | 0.03 | 0.015 | 0.25 | - | - | - | - | - | BAL. |

| Gr3 | 0.3 | 0.08 | 0.05 | 0.015 | 0.35 | - | - | - | - | - | BAL. |

| Gr4 | 0.3 | 0.08 | 0.05 | 0.015 | 0.40 | - | - | - | - | - | BAL |

| Gr5 | 0.25 | 0.08 | 0.03 | 0.015 | 0.02 | 5.5 - 6.75 | 3.5 - 4.5 | - | - | - | BAL |

| Gr7 | 0.3 | 0.08 | 0.03 | 0.015 | 0.25 | - | - | - | - | 0.12 - 0.25 | BAL. |

| Gr9 | 0.25 | 0.08 | 0.03 | 0.015 | 0.15 | 2.5 – 3.3 | 2.0 - 3.0 | - | - | - | BAL. |

| Gr12 | 0.3 | 0.08 | 0.03 | 0.015 | 0.25 | - | - | 0.2 - 0.4 | 0.6 - 0.9 | - | BAL. |

| Gr23 | 0.3 | 0.08 | 0.03 | 0.015 | 0.13 | 5.5 - 6.75 | - | - | - | - | B |