Titàn estanda pati

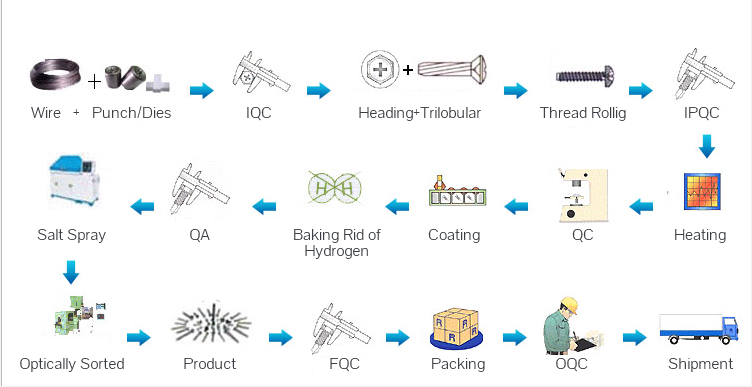

Pwodiksyon DIN, ANSI/AMSE, ISO, JIS ak lòt estanda ak Fastener Titàn ki pa estanda ki gen fòs segondè.Anjeneral gen ladan boulon, vis, nwa, rondelles, bag kenbe, ak divès kalite moso espesyal ki gen fòm.Premyerman, nou pral fè tretman chalè, tès konpozisyon chimik, tès pwopriyete mekanik nan ba Titàn, plak Titàn ak lòt materyèl debaz yo.Apre pwosesis la nan redresman, nivelman ak polisaj, koupe nan gwosè ki apwopriye a.Lè sa a, kontinye nan vire, Stamping cho, vis konpresyon, tretman chalè, polisaj, netwaye, enspeksyon, ak yon seri de pwosedi, evantyèlman yo pwodwi Fastener yo Titàn kalite siperyè.Nou gen ekipman pwodiksyon avanse ki asire pwodwi nou yo reyalize pi bon an nan chak lyen pwodiksyon an.

Konpayi nou an gen yon anpil nan envantè Fastener Titàn, ki ka satisfè ti kantite mondyal la nan lòd ak kliyan sa yo ki gen kondisyon livrezon ijan.An menm tan an, nou menm tou nou bay pwodwi ki pa estanda dapre desen kliyan yo bay yo.

Aplikasyon

Petwòl, metaliji, pwodui chimik, elektwonik, pharmaceutique, jeni marin, pati oto, pati motosiklèt, pati bisiklèt, akseswa yatch, founiti pou siviv deyò, machandiz espòtif ak lòt jaden.

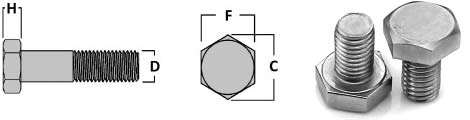

Titàn boulon

| Pwodwi | Titàn ak Titàn alyaj boulon |

| Gwosè | Dyamèt: M1.6-M30, Longè: 10mm-300mm (0.39″-11.8″) |

| Materyèl | Gr.1, Gr.2, Gr.5, Gr.7 elatriye |

| Estanda | DIN912, DIN6912, DIN933, DIN931 elatriye |

Titàn nwa hex

| Pwodwi | Titàn ak nwa alyaj Titàn |

| Gwosè | M8-M 80 x 6 |

| Materyèl | Gr1, Gr2, Gr5, Gr7, Ti6Al4V ELI, elatriye |

| Estanda | DIN, ISO, JIS, elatriye. |

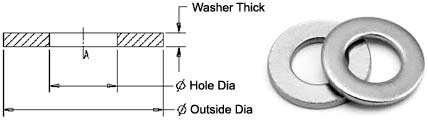

Tmachin pou lave itanium

| Pwodwi | Titàn ak lave alyaj Titàn |

| Gwosè | OD: 5mm-200mm (0.20″-7.87″), ID: 1mm-100mm (0.04″-3.94″), epesè: 0.1mm-30mm (0.004″-1.18″) |

| Materyèl | Gr.2, Gr.5 elatriye |

| Estanda | DIN125 elatriye |

Titàn vis

| Pwodwi | Titàn ak Titàn alyaj vis |

| Gwosè | M1 rive M42, Longè: 10mm-300mm (0.39″-11.8″) |

| Materyèl | Gr1, Gr.2, Gr.5, Gr.7, Gr.12 elatriye |

| Estanda | DIN912, DIN933, DIN84, DIN85, DIN963, DIN7991, DIN6912, DIN931, ISO7380, elatriye. |

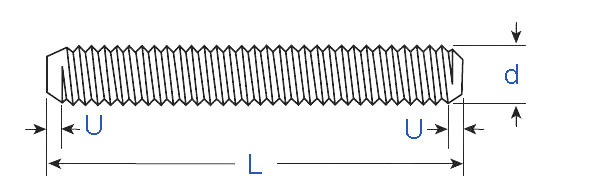

Titàn threaded stud

| Pwodwi | Titàn ak Titàn alyaj Threaded stud |

| Gwosè | Dyamèt: M1.6-M30, Longè: 10mm-300mm (0.39″-11.8″) |

| Materyèl | Gr.1, Gr.2, Gr.5, Gr.7, Gr.23 elatriye |

| Estanda | DIN912, DIN933, DIN7991, DIN7984, DIN6921, ISO 7380, JIS, BS elatriye. |

Titàn Egzagòn boulon dimansyon

| Gwo Hex Bolt Dyamèt | D | F | C | H | |||||

| Dyamèt kò | Lajè atravè Flats | Lajè atravè kwen yo | Wotè | ||||||

| Max | Debaz | Max | Min | Max | Min | Debaz | Max | Min | |

| 1/2 | 0.515 | 7/8 | 0.875 | 0.850 | 1.010 | 0.969 | 32/11 | 0.364 | 0.302 |

| 5/8 | 0.642 | 1-1/16 | 1.062 | 1.031 | 1.227 | 1.175 | 27/64 | 0.444 | 0.378 |

| 3/4 | 0.768 | 1-1/4 | 1.250 | 1.212 | 1.443 | 1.383 | 1/2 | 0.524 | 0.455 |

| 7/8 | 0.895 | 1-7/16 | 1.438 | 1.394 | 1.660 | 1.589 | 37/64 | 0.604 | 0.531 |

| 1 | 1.022 | 1-5/8 | 1.625 | 1.575 | 1.876 | 1.796 | 43/64 | 0.700 | 0.591 |

| 1-1/8 | 1.149 | 1-13/16 | 1.812 | 1.756 | 2.093 | 2.002 | 3/4 | 0.780 | 0.658 |

| 1-1/4 | 1.277 | 2 | 2.00 | 1.938 | 2.309 | 2.209 | 27/32 | 0.876 | 0.749 |

| 1-3/8 | 1.404 | 2-3/16 | 2.188 | 2.119 | 2.526 | 2.416 | 29/32 | 0.940 | 0.810 |

| 1-1/2 | 1.531 | 2-3/8 | 2.375 | 2.300 | 2.742 | 2.622 | 1 | 1.036 | 0.902 |

| 1-3/4 | 1.785 | 2-3/4 | 2.750 | 2.662 | 3.175 | 3.035 | 1-5/32 | 1.196 | 1.054 |

| 2 | 2.039 | 3-1/8 | 3.125 | 3.025 | 3.608 | 3.449 | 1-11/32 | 1.388 | 1.175 |

| 2-1/4 | 2.305 | 3-1/2 | 3.500 | 3.388 | 4.041 | 3.862 | 1-1/2 | 1.548 | 1.327 |

| 2-1/2 | 2.559 | 3-7/8 | 3.875 | 3.750 | 4.474 | 4.275 | 1-21/32 | 1.708 | 1.479 |

Egzagòn nwa dimansyon

| ISO Titàn Hex Nut NB | Atravè Kwen | MAX epesè | MIN Epesè | MAX atravè Flats | MIN Atravè Flats |

| M 8 | 14.38 | 6.8 | 6.44 | 13 | 12.73 |

| M 10 | 17.77 | 8.4 | 8.04 | 16 | 15.73 |

| M 12 | 20.03 | 10.8 | 10.37 | 18 | 17.73 |

| M 14 | 23.35 | 12.8 | 12.1 | 21 | 20.67 |

| M 16 | 26.75 | 14.8 | 14.1 | 24 | 23.67 |

| M 18 | 29.56 | 15.8 | 15.1 | 27 | 26.16 |

| M 20 | 32.95 | 18 | 16.9 | 30 | 29.16 |

| M 22 | 37.29 | 19.4 | 18.1 | 34 | 33 |

| M 24 | 39.55 | 21.5 | 20.2 | 36 | 35 |

| M 27 | 45.2 | 23.8 | 22.5 | 41 | 40 |

| M 30 | 50.85 | 26.6 | 24.3 | 46 | 45 |

| M 33 | 55.37 | 28.7 | 27.4 | 50 | 49 |

| M 36 | 60.79 | 31 | 29.4 | 55 | 53.8 |

| M 39 | 66.44 | 33.4 | 31.8 | 60 | 58.8 |

| M 42 | 71.3 | 34 | 32.4 | 65 | 63.1 |

| M 45 | 76.95 | 36 | 34.4 | 70 | 68.1 |

| M 48 | 82.6 | 38 | 39.4 | 75 | 73.1 |

| M 52 | 88.25 | 42 | 40.4 | 80 | 78.1 |

| M 56 | 93.56 | 45 | 43.4 | 85 | 82.8 |

| M 60 | 99.21 | 48 | 46.4 | 90 | 87.8 |

| M 64 | 104.86 | 51 | 49.1 | 95 | 92.8 |

| M 68 | 110.51 | 54 | 52.1 | 100 | 97.8 |

| M 72 x 6 | 116.16 | 58 | 56.1 | 105 | 102.8 |

| M 76 x 6 | 121.81 | 61 | 59.1 | 110 | 107.8 |

| M 80 x 6 | 127.46 | 64 | 62.1 | 115 | 112.8 |

Titàn plat pou lave dimansyon

| Ti Alloy Bolt Size | USS | SAE | ||||

| OD (pous.) | ID (pous) | Epesè | OD (pous.) | ID (pous) | Epesè | |

| 1/8 (#6) | - | - | - | 0.375 | 0.156 | .036/.065 |

| 5/32 (#8) | - | - | - | 0.438 | 0.188 | .036/.065 |

| 3/16 (#10) | 0.560 | 0.250 | .036/.065 | 0.500 | 0.220 | .036/.065 |

| 7/32 (#12) | - | - | - | 0.562 | 0.250 | .051/.080 |

| 1/4 (#14) | 0.734 | 0.312 | .051/.080 | 0.625 | 0.281 | .051/.080 |

| 5/16 | 0.875 | 0.375 | .064/.104 | 0.688 | 0.344 | .051/.080 |

| 3/8 | 1.000 | 0.438 | .064/.104 | 0.812 | 0.406 | .051/.080 |

| 7/16 | 1.250 | 0.500 | .064/.104 | 0.922 | 0.469 | .051/.080 |

| 1/2 | 1.375 | 0.562 | .086/.132 | 1.062 | 0.531 | .074/.121 |

| 9/16 | 1.469 | 0.625 | .086/.132 | 1.156 | 0.594 | .074/.121 |

| 5/8 | 1.750 | 0.688 | .108/.160 | 1.312 | 0.656 | .074/.121 |

| 3/4 | 2.000 | 0.812 | .122/.177 | 1.469 | 0.812 | .108/.160 |

| 7/8 | 2.250 | 0.938 | .136/.192 | 1.750 | 0.938 | .108/.160 |

| 1 | 2.500 | 1.062 | .136/.192 | 2.000 | 1.062 | .108/.160 |

| 1 1/8 | 2.750 | 1.250 | .136/.192 | 2.250 | 1.250 | .108/.160 |

| 1 1/4 | 3.000 | 1.375 | .136/.192 | 2.500 | 1.375 | .136/.192 |

| 1 3/8 | 3.250 | 1.500 | .153/.213 | 2.750 | 1.500 | .136/.213 |

| 1 1/2 | 3.500 | 1.625 | .153/.213 | 3.000 | 1.625 | .153/.213 |

| 1 5/8 | 3.750 | 1.750 | .153/.213 | - | - | - |

| 1 3/4 | 4.000 | 1.875 | .153/.213 | - | - | - |

| 1 7/8 | 4.250 | 2.000 | .153/.213 | - | - | - |

| 2 | 4.500 | 2.125 | .153/.213 | - | - | - |

| 2 1/4 | 4.750 | 2.375 | .193/.248 | - | - | - |

| 2 1/2 | 5.000 | 2.625 | .210/.280 | - | - | - |

| 2 3/4 | 5.250 | 2.875 | .228/.310 | - | - | - |

| 3 | 5.500 | 3.125 | .249/.327 | - | - | - |

Socket Head Cap Screw Dimansyon

| Ti Alloy Screw Nom.Size Thread Pitch | Kò | Tèt | Tèt | Chanfrein | Egzagòn | Spline | Kle | Tranzisyon | |||

| Max | Min | Max | Min | Max | Min | Max | Nom. | Nom. | Min | Max | |

| M1.6 × 0.35 | 1.60 | 1.46 | 3.00 | 2.87 | 1.60 | 1.52 | 0.16 | 1.5 | 1.829 | 0.80 | 2.0 |

| M2 × 0.4 | 2.00 | 1.86 | 3.80 | 3.65 | 2.00 | 1.91 | 0.20 | 1.5 | 1.829 | 1.00 | 2.6 |

| M2.5 × 0.45 | 2.50 | 2.36 | 4.50 | 4.33 | 2.50 | 2.40 | 0.25 | 2.0 | 2.438 | 1.25 | 3.1 |

| M3 × 0.5 | 3.00 | 2.86 | 5.50 | 5.32 | 3.00 | 2.89 | 0.30 | 2.5 | 2.819 | 1.50 | 3.6 |

| M4 × 0.7 | 4.00 | 3.82 | 7.00 | 6.80 | 4.00 | 3.88 | 0.40 | 3.0 | 3.378 | 2.00 | 4.7 |

| M5 × 0.8 | 5.00 | 4.82 | 8.50 | 8.27 | 5.00 | 4.86 | 0.50 | 4.0 | 4.648 | 2.50 | 5.7 |

| M6 × 1 | 6.00 | 5.82 | 10.00 | 9.74 | 6.00 | 5.85 | 0.60 | 5.0 | 5.486 | 3.00 | 6.8 |

| M8 × 1.25 | 8.00 | 7.78 | 13.00 | 12.70 | 8.00 | 7.83 | 0.80 | 6.0 | 7.391 | 4.00 | 9.2 |

| M10 × 1.5 | 10.00 | 9.78 | 16.00 | 15.67 | 10.00 | 9.81 | 1.00 | 8.0 | … | 5.00 | 11.2 |

| M12 × 1.75 | 12.00 | 11.73 | 18.00 | 17.63 | 12.00 | 11.79 | 1.20 | 10.0 | … | 6.00 | 14.2 |

| M14 × 2b | 14.00 | 13.73 | 21.00 | 20.60 | 14.00 | 13.77 | 1.40 | 12.0 | … | 7.00 | 16.2 |

| M16 × 2 | 16.00 | 15.73 | 24.00 | 23.58 | 16.00 | 15.76 | 1.60 | 14.0 | … | 8.00 | 18.2 |

| M20 × 2.5 | 20.00 | 19.67 | 30.00 | 29.53 | 20.00 | 19.73 | 2.00 | 17.0 | … | 10.00 | 22.4 |

| M24 × 3 | 24.00 | 23.67 | 36.00 | 35.48 | 24.00 | 23.70 | 2.40 | 19.0 | … | 12.00 | 26.4 |

| M30 × 3.5 | 30.00 | 29.67 | 45.00 | 44.42 | 30.00 | 29.67 | 3.00 | 22.0 | … | 15.00 | 33.4 |

| M36 × 4 | 36.00 | 35.61 | 54.00 | 53.37 | 36.00 | 35.64 | 3.60 | 27.0 | … | 18.00 | 39.4 |

| M42 × 4.5 | 42.00 | 41.61 | 63.00 | 62.31 | 42.00 | 41.61 | 4.20 | 32.0 | … | 21.00 | 45.6 |

| M48 × 5 | 48.00 | 47.61 | 72.00 | 71.27 | 48.00 | 47.58 | 4.80 | 36.0 | … | 24.00 | |

Titàn threaded stud

| ANSI / ASMEB 18.31.2 Threaded Rods-Inite: pous | ||||

| d | anplasman | |||

| UNC | UNF | 8UN | ||

| 1/4 | 0.25 | 20 | 28 | / |

| 5/16 | 0.3125 | 18 | 24 | / |

| 3/8 | 0.375 | 18 | 24 | / |

| 7/16 | 0.4375 | 14 | 20 | / |

| 1/2 | 0.5 | 13 | 20 | / |

| 9/16 | 0.5625 | 12 | 18 | / |

| 5/8 | 0.625 | 11 | 18 | / |

| 3/4 | 0.75 | 10 | 16 | / |

| 7/8 | 0.875 | 9 | 14 | / |

| 1 | 1 | 8 | 12 | 8 |

| 1-1/8 | 1.125 | 7 | 12 | 8 |

| 1-1/4 | 1.25 | 7 | 12 | 8 |

| 1-3/8 | 1.375 | 6 | 12 | 8 |

| Inite: pous | ||||

| d | anplasman | |||

| UNC | UNF | 8UN | ||

| 1-1/2 | 1.5 | 6 | 12 | 8 |

| 1-5/8 | 1.625 | / | / | 8 |

| 1-3/7 | 1.75 | 5 | / | 8 |

| 1-7/8 | 1.875 | / | / | 8 |

| 2 | 2 | 4-1/2 | / | 8 |

| 2-1/4 | 2.25 | 4-1/2 | / | 8 |

| 2-1/2 | 2.5 | 4 | / | 8 |

| 2-3/4 | 2.75 | 4 | / | 8 |

| 3 | 3 | 4 | / | 8 |

| 3-1/4 | 3.25 | 4 | / | 8 |

| 3-1/2 | 3.5 | 4 | / | 8 |

| 3-3/4 | 3.75 | 4 | / | 8 |

| 4 | 4 | 4 | / | 8 |

| L | 1/2<L≤2-1/2 | 2-1/2<L≤4 | 4<L≤8 | 8<L≤16 | 16<L |

| Tolerans longè stud tache | ±0.04 | ±0.08 | ± 0.10 | ±0.12 | ±0.18 |

| Estanda | Deskripsyon | Estanda | Deskripsyon |

| DIN 84 | Fwomaj tèt vis | DIN 439 | Konfiti nwa |

| DIN 125 | Rondye plat | DIN 963 | Slotted vis tèt plat |

| DIN 127 | Spring lock rondelles | DIN 965 | Phillips tèt plat machin vis |

| DIN 912 | Vis bouchon tèt priz hex | DIN 985 | Fèmen nwa (ak insert ki pa metalik) |

| DIN913/DIN 914/DIN915/DIN916 | Mete vis | DIN 1665/DIN 6921 | Boulon Egzagòn ak bride |

| DIN 931 | Vis tèt Egzagòn (pati fil) | DIN 6912/DIN 7984 | Egzagòn priz tèt mens vis bouchon |

| DIN 933 | Vis tèt Egzagòn (fil konplè) | DIN 7991 | Tèt plat countersunk priz bouchon vis |

| DIN 934 | Nwa Egzagòn | DIN 9021 | Machin pou lave plat |

Klas ekivalan materyèl pou Fastener Titanium

| STANDARD | WERKSTOFF NR. | UNS |

| Titàn Grade 2 | 3.7035 | R50400 |

| Titàn Grade 5 | 3.7165 | R56400 |

Karakteristik mekanik nan Fastener Titàn

| Klas | Fòs rupture (min) | Sede fòs 0.2% Offset | Elongasyon nan 2 pous oswa 50mm% (min) | ||

| KSI | MPa | KSI | MPa | ||

| Gr.1 | 35 | 240 | 20-45 | 138-310 | 24 |

| Gr.2 | 50 | 345 | 40-65 | 275-450 | 20 |

| Gr.3 | 65 | 450 | 55-80 | 380-550 | 18 |

| Gr.4 | 80 | 550 | ≥70 | ≥483 | 15 |

| Gr.5 | 138 | 950 | ≥128 | ≥880 | 14 |

| Gr.7 | 50 | 345 | ≥40 | ≥275 | 24 |

| Gr.9 | 125 | 860 | ≥105 | ≥725 | 10 |

| Gr.12 | 70 | 483 | ≥50 | ≥345 | 18 |

| Gr.23 | 125 | 860 | ≥115 | ≥790 | 15 |

| Eleman | Dansite | Pwen k ap fonn | Fòs rupture | Fòs Sede (0.2% Offset) | Elongasyon |

| Titàn Gr.2 | 4.5 g/cm3 | 1665 °C (3030 °F) | Psi - 49900, MPa - 344 | Psi - 39900, MPa - 275 | 20% |

| Titàn Gr.5 | 4.43 g/cm3 | 1632 °C (2970 °F) | Psi - 138000, MPa - 950 | Psi - 128000, MPa - 880 | 14% |

Materyèl Chimik Konpozisyon Titàn Fastener

| Klas | Fe% | C% | N% | H% | O% | Al% | V% | Mo% | Ni% | Pd% | Ti |

| Gr1 | 0.2 | 0.08 | 0.03 | 0.015 | 0.18 | — | — | — | — | — | BAL. |

| Gr2 | 0.3 | 0.08 | 0.03 | 0.015 | 0.25 | — | — | — | — | — | BAL. |

| Gr3 | 0.3 | 0.08 | 0.05 | 0.015 | 0.35 | — | — | — | — | — | BAL. |

| Gr4 | 0.3 | 0.08 | 0.05 | 0.015 | 0.40 | — | — | — | — | — | BAL |

| Gr5 | 0.25 | 0.08 | 0.03 | 0.015 | 0.02 | 5.5 - 6.75 | 3.5 - 4.5 | — | — | — | BAL |

| Gr7 | 0.3 | 0.08 | 0.03 | 0.015 | 0.25 | — | — | — | — | 0.12 - 0.25 | BAL. |

| Gr9 | 0.25 | 0.08 | 0.03 | 0.015 | 0.15 | 2.5 - 3.3 | 2.0 - 3.0 | — | — | — | BAL. |

| Gr12 | 0.3 | 0.08 | 0.03 | 0.015 | 0.25 | — | — | 0.2 - 0.4 | 0.6 - 0.9 | — | BAL. |

| Gr23 | 0.3 | 0.08 | 0.03 | 0.015 | 0.13 | 5.5 - 6.75 | — | — | — | — | B |