Akụkụ ọkọlọtọ Titanium

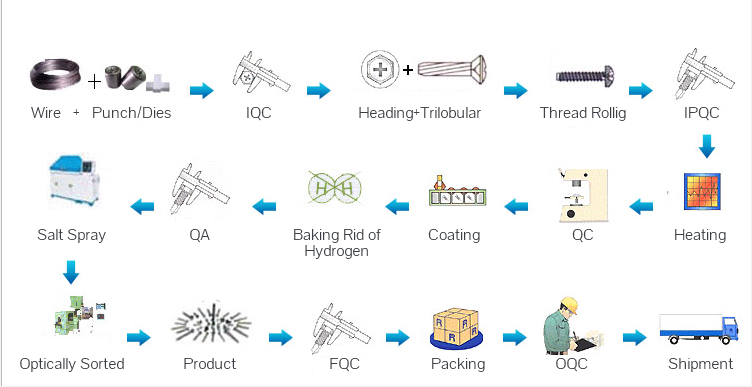

Mmepụta nke DIN, ANSI / AMSE, ISO, JIS na ụkpụrụ ndị ọzọ na ndị na-abụghị ọkọlọtọ titanium fasteners.Na-agụnyekarị bolts, skru, nuts, washers, retaining ring, na ụdị dị iche iche nwere ụdị pụrụ iche.Nke mbụ, anyị ga-eme ọgwụgwọ okpomọkụ, nyocha ihe mejupụtara kemịkalụ, nyocha ihe eji arụ ọrụ nke ogwe titanium, efere titanium na ihe ndị ọzọ bụ isi.Mgbe usoro ịgbatị, nhazi na polishing, bee n'ime nha kwesịrị ekwesị.Ma wee gaa n'ihu na-atụgharị, stamping na-ekpo ọkụ, mkpakọ mkpakọ, ọgwụgwọ okpomọkụ, polishing, ihicha, nyocha, na usoro usoro, n'ikpeazụ iji mepụta titanium fasteners dị elu.Anyị nwere ngwá ọrụ mmepụta ihe dị elu nke mere ka ngwaahịa anyị nweta ihe kacha mma na njikọ mmepụta ọ bụla.

Ụlọ ọrụ anyị nwere ọtụtụ ngwa ahịa titanium fasteners, nke nwere ike imeju obere iwu zuru ụwa ọnụ na ndị ahịa ahụ nwere mkpa nnyefe ngwa ngwa.N'otu oge ahụ, anyị na-enyekwa ngwaahịa ndị na-abụghị ọkọlọtọ dịka eserese nke ndị ahịa nyere.

Ngwa

Petroleum, metallurgy, chemical, electronic, pharmaceutical, injinia mmiri, akụkụ ụgbọ ala, akụkụ ọgba tum tum, akụkụ igwe kwụ otu ebe, ngwa ụgbọ mmiri, ihe ịlanarị n'èzí, ngwa egwuregwu na ubi ndị ọzọ.

Titanium mkpuchi

| Ngwaahịa | Titanium na Titanium alloy bolt |

| Nha | Dayameta: M1.6-M30, Ogologo: 10mm-300mm (0.39″-11.8″) |

| Ihe onwunwe | Gr.1, Gr.2, Gr.5, Gr.7 wdg |

| Ọkọlọtọ | DIN912, DIN6912, DIN933, DIN931 wdg |

Titanium hex nut

| Ngwaahịa | Titanium na Titanium alloy nut |

| Nha | M8-M 80 x 6 |

| Ihe onwunwe | Gr1, Gr2, Gr5, Gr7, Ti6Al4V ELI, wdg |

| Ọkọlọtọ | DIN, ISO, JIS, wdg. |

Titanium washer

| Ngwaahịa | Titanium na Titanium alloy washer |

| Nha | OD: 5mm-200mm (0.20″-7.87″), NJ: 1mm-100mm (0.04″-3.94″), ọkpụrụkpụ: 0.1mm-30mm (0.004″-1.18″) |

| Ihe onwunwe | Gr.2, Gr.5 wdg |

| Ọkọlọtọ | DIN125 wdg |

Titanium kposara

| Ngwaahịa | Titanium na titanium alloy kposara |

| Nha | M1 ruo M42, Ogologo: 10mm-300mm (0.39 ″-11.8″) |

| Ihe onwunwe | Gr1, Gr.2, Gr.5, Gr.7, Gr.12 wdg |

| Ọkọlọtọ | DIN912, DIN933, DIN84, DIN85, DIN963, DIN7991, DIN6912, DIN931, ISO7380, wdg. |

Titanium eriri stud

| Ngwaahịa | Titanium na Titanium alloy threaded stud |

| Nha | Dayameta: M1.6-M30, Ogologo: 10mm-300mm (0.39″-11.8″) |

| Ihe onwunwe | Gr.1, Gr.2, Gr.5, Gr.7, Gr.23 wdg |

| Ọkọlọtọ | DIN912, DIN933, DIN7991, DIN7984, DIN6921, ISO 7380, JIS, BS wdg. |

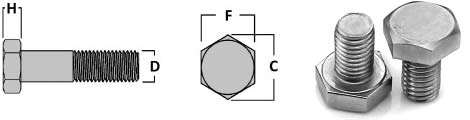

Titanium Hex Bolts Akụkụ

| Dayameta Hex Bolt dị arọ | D | F | C | H | |||||

| Dayameta ahụ | Obosara n'ofe Flat | Obosara gafee nkuku | Ogologo | ||||||

| Oke | Isi | Oke | Min | Oke | Min | Isi | Oke | Min | |

| 1/2 | 0,515 | 7/8 | 0,875 | 0,850 | 1.010 | 0,969 | 11/32 | 0,364 | 0,302 |

| 5/8 | 0,642 | 1-1/16 | 1.062 | 1.031 | 1.227 | 1.175 | 27/64 | 0,444 | 0,378 |

| 3/4 | 0,768 | 1-1/4 | 1.250 | 1.212 | 1.443 | 1.383 | 1/2 | 0,524 | 0,455 |

| 7/8 | 0,895 | 1-7/16 | 1.438 | 1.394 | 1.660 | 1.589 | 37/64 | 0.604 | 0,531 |

| 1 | 1.022 | 1-5/8 | 1.625 | 1.575 | 1.876 | 1.796 | 43/64 | 0,700 | 0,591 |

| 1-1/8 | 1.149 | 1-13/16 | 1.812 | 1.756 | 2.093 | 2.002 | 3/4 | 0,780 | 0,658 |

| 1-1/4 | 1.277 | 2 | 2.00 | 1,938 | 2.309 | 2.209 | 27/32 | 0,876 | 0,749 |

| 1-3/8 | 1.404 | 2-3/16 | 2.188 | 2.119 | 2.526 | 2.416 | 29/32 | 0,940 | 0,810 |

| 1-1/2 | 1.531 | 2-3/8 | 2,375 | 2.300 | 2.742 | 2.622 | 1 | 1.036 | 0,902 |

| 1-3/4 | 1.785 | 2-3/4 | 2.750 | 2.662 | 3.175 | 3.035 | 1-5/32 | 1.196 | 1.054 |

| 2 | 2.039 | 3-1/8 | 3.125 | 3.025 | 3.608 | 3,449 | 1-11/32 | 1.388 | 1.175 |

| 2-1/4 | 2.305 | 3-1/2 | 3.500 | 3,388 | 4.041 | 3,862 | 1-1/2 | 1.548 | 1.327 |

| 2-1/2 | 2.559 | 3-7/8 | 3,875 | 3.750 | 4,474 | 4.275 | 1-21/32 | 1.708 | 1,479 |

Akụkụ Hex Nuts

| ISO Titanium Hex Nut NB | N'ofe akụkụ | Ọkpụrụkpụ MAX | Ọkpụrụkpụ MIN | MAX gafere Flat | MIN gafere Flat |

| M 8 | 14.38 | 6.8 | 6.44 | 13 | 12.73 |

| M 10 | 17.77 | 8.4 | 8.04 | 16 | 15.73 |

| M 12 | 20.03 | 10.8 | 10.37 | 18 | 17.73 |

| M 14 | 23.35 | 12.8 | 12.1 | 21 | 20.67 |

| M 16 | 26.75 | 14.8 | 14.1 | 24 | 23.67 |

| M 18 | 29.56 | 15.8 | 15.1 | 27 | 26.16 |

| M 20 | 32.95 | 18 | 16.9 | 30 | 29.16 |

| M 22 | 37.29 | 19.4 | 18.1 | 34 | 33 |

| M 24 | 39.55 | 21.5 | 20.2 | 36 | 35 |

| M 27 | 45.2 | 23.8 | 22.5 | 41 | 40 |

| M 30 | 50.85 | 26.6 | 24.3 | 46 | 45 |

| M 33 | 55.37 | 28.7 | 27.4 | 50 | 49 |

| M 36 | 60.79 | 31 | 29.4 | 55 | 53.8 |

| M 39 | 66.44 | 33.4 | 31.8 | 60 | 58.8 |

| M 42 | 71.3 | 34 | 32.4 | 65 | 63.1 |

| M 45 | 76.95 | 36 | 34.4 | 70 | 68.1 |

| M 48 | 82.6 | 38 | 39.4 | 75 | 73.1 |

| M 52 | 88.25 | 42 | 40.4 | 80 | 78.1 |

| M 56 | 93.56 | 45 | 43.4 | 85 | 82.8 |

| M 60 | 99.21 | 48 | 46.4 | 90 | 87.8 |

| M 64 | 104.86 | 51 | 49.1 | 95 | 92.8 |

| M 68 | 110.51 | 54 | 52.1 | 100 | 97.8 |

| M 72 x 6 | 116.16 | 58 | 56.1 | 105 | 102.8 |

| M 76 x6 | 121.81 | 61 | 59.1 | 110 | 107.8 |

| M 80 x 6 | 127.46 | 64 | 62.1 | 115 | 112.8 |

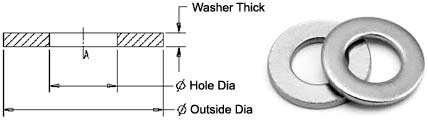

Akụkụ Titanium Flat Washer Akụkụ

| Nke Alloy Bolt Size | USS | SAE | ||||

| OD (n'ime) | ID (n'ime.) | Ọkpụrụkpụ | OD (n'ime) | ID (n'ime.) | Ọkpụrụkpụ | |

| 1/8 (#6) | - | - | - | 0,375 | 0.156 | .036/.065 |

| 5/32 (#8) | - | - | - | 0,438 | 0.188 | .036/.065 |

| 3/16 (#10) | 0,560 | 0,250 | .036/.065 | 0,500 | 0.220 | .036/.065 |

| 7/32 (#12) | - | - | - | 0,562 | 0,250 | .051/.080 |

| 1/4 (#14) | 0,734 | 0,312 | .051/.080 | 0,625 | 0.281 | .051/.080 |

| 5/16 | 0,875 | 0,375 | .064/.104 | 0,688 | 0,344 | .051/.080 |

| 3/8 | 1.000 | 0,438 | .064/.104 | 0,812 | 0,406 | .051/.080 |

| 7/16 | 1.250 | 0,500 | .064/.104 | 0,922 | 0,469 | .051/.080 |

| 1/2 | 1.375 | 0,562 | .086/.132 | 1.062 | 0,531 | .074/.121 |

| 9/16 | 1.469 | 0,625 | .086/.132 | 1.156 | 0,594 | .074/.121 |

| 5/8 | 1.750 | 0,688 | .108/.160 | 1.312 | 0,656 | .074/.121 |

| 3/4 | 2.000 | 0,812 | .122/.177 | 1.469 | 0,812 | .108/.160 |

| 7/8 | 2.250 | 0,938 | .136/192 | 1.750 | 0,938 | .108/.160 |

| 1 | 2.500 | 1.062 | .136/192 | 2.000 | 1.062 | .108/.160 |

| 1 1/8 | 2.750 | 1.250 | .136/192 | 2.250 | 1.250 | .108/.160 |

| 1 1/4 | 3.000 | 1.375 | .136/192 | 2.500 | 1.375 | .136/192 |

| 1 3/8 | 3.250 | 1.500 | .153/.213 | 2.750 | 1.500 | .136/.213 |

| 1 1/2 | 3.500 | 1.625 | .153/.213 | 3.000 | 1.625 | .153/.213 |

| 1 5/8 | 3.750 | 1.750 | .153/.213 | - | - | - |

| 1 3/4 | 4.000 | 1.875 | .153/.213 | - | - | - |

| 1 7/8 | 4.250 | 2.000 | .153/.213 | - | - | - |

| 2 | 4.500 | 2.125 | .153/.213 | - | - | - |

| 2 1/4 | 4.750 | 2,375 | .193/.248 | - | - | - |

| 2 1/2 | 5,000 | 2.625 | .210/.280 | - | - | - |

| 2 3/4 | 5.250 | 2,875 | .228/.310 | - | - | - |

| 3 | 5.500 | 3.125 | .249 / .327 | - | - | - |

Socket Head Cap Screw Screw Dimensions

| Ti Alloy Screw Nom.Nha eriri eriri | Ahụ | Isi | Isi | Chamfer | Hexagon | Spline | Igodo | Mgbanwe | |||

| Oke | Min | Oke | Min | Oke | Min | Oke | Nọmba. | Nọmba. | Min | Oke | |

| M1.6 × 0.35 | 1.60 | 1.46 | 3.00 | 2.87 | 1.60 | 1.52 | 0.16 | 1.5 | 1.829 | 0.80 | 2.0 |

| M2 × 0.4 | 2.00 | 1.86 | 3.80 | 3.65 | 2.00 | 1.91 | 0.20 | 1.5 | 1.829 | 1.00 | 2.6 |

| M2.5 × 0.45 | 2.50 | 2.36 | 4.50 | 4.33 | 2.50 | 2.40 | 0.25 | 2.0 | 2.438 | 1.25 | 3.1 |

| M3 × 0.5 | 3.00 | 2.86 | 5.50 | 5.32 | 3.00 | 2.89 | 0.30 | 2.5 | 2.819 | 1.50 | 3.6 |

| M4 × 0.7 | 4.00 | 3.82 | 7.00 | 6.80 | 4.00 | 3.88 | 0.40 | 3.0 | 3,378 | 2.00 | 4.7 |

| M5 × 0.8 | 5.00 | 4.82 | 8.50 | 8.27 | 5.00 | 4.86 | 0,50 | 4.0 | 4,648 | 2.50 | 5.7 |

| M6 × 1 | 6.00 | 5.82 | 10.00 | 9.74 | 6.00 | 5.85 | 0.60 | 5.0 | 5,486 | 3.00 | 6.8 |

| M8 × 1.25 | 8.00 | 7.78 | 13.00 | 12.70 | 8.00 | 7.83 | 0.80 | 6.0 | 7,391 | 4.00 | 9.2 |

| M10 × 1.5 | 10.00 | 9,78 | 16.00 | 15.67 | 10.00 | 9.81 | 1.00 | 8.0 | … | 5.00 | 11.2 |

| M12 × 1.75 | 12.00 | 11.73 | 18.00 | 17.63 | 12.00 | 11.79 | 1.20 | 10.0 | … | 6.00 | 14.2 |

| M14 × 2b | 14.00 | 13.73 | 21.00 | 20.60 | 14.00 | 13.77 | 1.40 | 12.0 | … | 7.00 | 16.2 |

| M16 × 2 | 16.00 | 15.73 | 24.00 | 23.58 | 16.00 | 15.76 | 1.60 | 14.0 | … | 8.00 | 18.2 |

| M20 × 2.5 | 20.00 | 19.67 | 30.00 | 29.53 | 20.00 | 19.73 | 2.00 | 17.0 | … | 10.00 | 22.4 |

| M24 × 3 | 24.00 | 23.67 | 36.00 | 35.48 | 24.00 | 23.70 | 2.40 | 19.0 | … | 12.00 | 26.4 |

| M30 × 3.5 | 30.00 | 29.67 | 45.00 | 44.42 | 30.00 | 29.67 | 3.00 | 22.0 | … | 15.00 | 33.4 |

| M36 × 4 | 36.00 | 35.61 | 54.00 | 53.37 | 36.00 | 35.64 | 3.60 | 27.0 | … | 18.00 | 39.4 |

| M42 × 4.5 | 42.00 | 41.61 | 63.00 | 62.31 | 42.00 | 41.61 | 4.20 | 32.0 | … | 21.00 | 45.6 |

| M48 × 5 | 48.00 | 47.61 | 72.00 | 71.27 | 48.00 | 47.58 | 4.80 | 36.0 | … | 24.00 | |

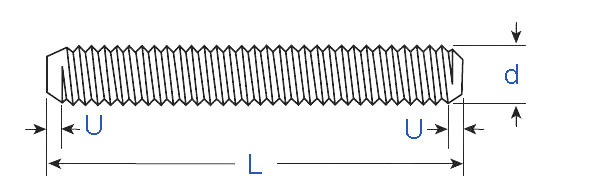

Titanium eriri stud

| ANSI /ASMEB 18.31.2 eriri eriri-Unit: inch | ||||

| d | pitch | |||

| UNC | UNF | 8 UN | ||

| 1/4 | 0.25 | 20 | 28 | / |

| 5/16 | 0,3125 | 18 | 24 | / |

| 3/8 | 0,375 | 18 | 24 | / |

| 7/16 | 0,4375 | 14 | 20 | / |

| 1/2 | 0.5 | 13 | 20 | / |

| 9/16 | 0,5625 | 12 | 18 | / |

| 5/8 | 0,625 | 11 | 18 | / |

| 3/4 | 0.75 | 10 | 16 | / |

| 7/8 | 0,875 | 9 | 14 | / |

| 1 | 1 | 8 | 12 | 8 |

| 1-1/8 | 1.125 | 7 | 12 | 8 |

| 1-1/4 | 1.25 | 7 | 12 | 8 |

| 1-3/8 | 1.375 | 6 | 12 | 8 |

| Nkeji: inch | ||||

| d | pitch | |||

| UNC | UNF | 8 UN | ||

| 1-1/2 | 1.5 | 6 | 12 | 8 |

| 1-5/8 | 1.625 | / | / | 8 |

| 1-3/7 | 1.75 | 5 | / | 8 |

| 1-7/8 | 1.875 | / | / | 8 |

| 2 | 2 | 4-1/2 | / | 8 |

| 2-1/4 | 2.25 | 4-1/2 | / | 8 |

| 2-1/2 | 2.5 | 4 | / | 8 |

| 2-3/4 | 2.75 | 4 | / | 8 |

| 3 | 3 | 4 | / | 8 |

| 3-1/4 | 3.25 | 4 | / | 8 |

| 3-1/2 | 3.5 | 4 | / | 8 |

| 3-3/4 | 3.75 | 4 | / | 8 |

| 4 | 4 | 4 | / | 8 |

| L | 1/2<L≤2-1/2 | 2-1/2<L≤4 | 4L≤8 | 8 ml≤16 | 16 L |

| Nkwenye ogologo stud gbasiri ike | ±0.04 | ±0.08 | ±0.10 | ±0.12 | ±0.18 |

| Ọkọlọtọ | Nkọwa | Ọkọlọtọ | Nkọwa |

| DIN 84 | Slotted cheese isi kposara | DIN 439 | Jam akụ |

| DIN 125 | Ndị na-asa akwa | DIN 963 | Mkpọsa isi ewepụghị oghere |

| DIN 127 | Mmiri mkpọchi washers | DIN 965 | Phillips flat head machine skru |

| DIN 912 | Hex sọket isi okpu kposara | DIN 985 | Mkpọchi mkpụrụ (ya na ntinye na-abụghị ọla) |

| DIN913/DIN 914/DIN915/DIN916 | Tọọ kposara | DIN 1665/DIN 6921 | Hex bolts nwere flange |

| DIN 931 | Okpu isi hex (eriri akụkụ) | DIN 6912/DIN 7984 | Oghe hexagon dị mkpa okpu isi skru |

| DIN 933 | skru isi hex (eriri zuru oke) | DIN 7991 | Isi ewepụghị isi countersunk okpu sọket |

| DIN 934 | Hex akụ | DIN 9021 | Igwe eji akwa akwa |

Ngosipụta ihe dakọtara maka ihe ntanye Titanium

| Ọkọlọtọ | Ọrụ NR. | UNS |

| Titanium ọkwa 2 | 3.7035 | R50400 |

| Titanium ọkwa 5 | 3.7165 | R56400 |

Njirimara igwe nke Titanium fasteners

| Ọkwa | Ike ntakiri (nkeji) | Mbipụta Ike 0.2% kwụsịrị | Mgbatị n'ime inch 2 ma ọ bụ 50mm% (nkeji) | ||

| KSI | MPa | KSI | MPa | ||

| Gr.1 | 35 | 240 | 20-45 | 138-310 | 24 |

| Gr.2 | 50 | 345 | 40-65 | 275-450 | 20 |

| Gr.3 | 65 | 450 | 55-80 | 380-550 | 18 |

| Gr.4 | 80 | 550 | ≥70 | ≥483 | 15 |

| Gr.5 | 138 | 950 | ≥128 | ≥880 | 14 |

| Gr.7 | 50 | 345 | ≥40 | ≥275 | 24 |

| Gr.9 | 125 | 860 | ≥105 | ≥725 | 10 |

| Gr.12 | 70 | 483 | ≥50 | ≥345 | 18 |

| Gr.23 | 125 | 860 | ≥115 | ≥790 | 15 |

| Ihe | Njupụta | Ebe Na-agbaze | Ike ọdụdọ | Ike Mpụta (0.2% kwụsịrị) | Ogologo oge |

| Titanium Gr.2 | 4.5 g/cm3 | 1665 Celsius (3030 Celsius) | Psi – 49900 , MPa – 344 | Psi – 39900 , MPa – 275 | 20% |

| Titanium Gr.5 | 4.43 g/cm3 | 1632 Celsius (2970 Celsius) | Psi – 138000, MPa – 950 | Psi – 128000 , MPa – 880 | 14% |

Ihe mejupụtara kemịkalụ nke Titanium fasteners

| Ọkwa | Fe% | C% | N% | H% | O% | Al% | V% | mo% | Ni% | Pd% | Ti |

| Gr1 | 0.2 | 0.08 | 0.03 | 0.015 | 0.18 | - | - | - | - | - | BAL. |

| Gr2 | 0.3 | 0.08 | 0.03 | 0.015 | 0.25 | - | - | - | - | - | BAL. |

| Gr3 | 0.3 | 0.08 | 0.05 | 0.015 | 0.35 | - | - | - | - | - | BAL. |

| Gr4 | 0.3 | 0.08 | 0.05 | 0.015 | 0.40 | - | - | - | - | - | BAL |

| Gr5 | 0.25 | 0.08 | 0.03 | 0.015 | 0.02 | 5.5-6.75 | 3.5-4.5 | - | - | - | BAL |

| Gr7 | 0.3 | 0.08 | 0.03 | 0.015 | 0.25 | - | - | - | - | 0.12-0.25 | BAL. |

| Gr9 | 0.25 | 0.08 | 0.03 | 0.015 | 0.15 | 2.5-3.3 | 2.0-3.0 | - | - | - | BAL. |

| Gr12 | 0.3 | 0.08 | 0.03 | 0.015 | 0.25 | - | - | 0.2-0.4 | 0.6-0.9 | - | BAL. |

| Gr23 | 0.3 | 0.08 | 0.03 | 0.015 | 0.13 | 5.5-6.75 | - | - | - | - | B |