Titanium standar bagean

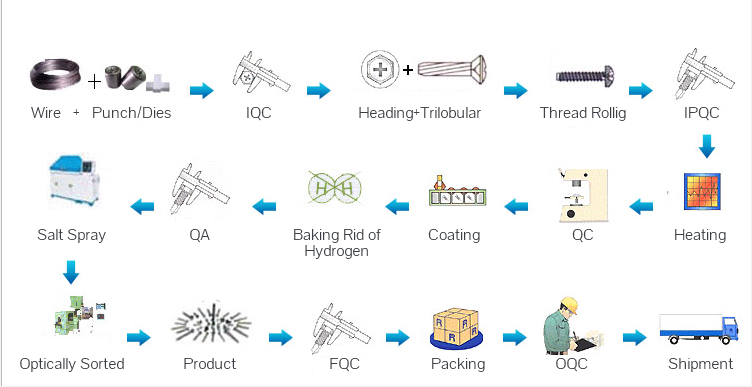

Produksi DIN, ANSI / AMSE, ISO, JIS lan standar liyane lan non-standar dhuwur-kekuatan titanium fasteners.Biasane kalebu baut, sekrup, kacang, mesin cuci, dering penahan, lan macem-macem potongan khusus.Kaping pisanan, kita bakal nindakake perawatan panas, uji komposisi kimia, uji sifat mekanik bar titanium, piring titanium lan bahan dhasar liyane.Sawise proses straightening, leveling lan polishing, dipotong dadi ukuran sing cocog.Lan banjur nerusake kanggo ngowahi, stamping panas, meneng komprèsi, perawatan panas, polishing, reresik, pengawasan, lan seri saka tata cara, pungkasanipun kanggo gawé fasteners titanium kualitas dhuwur.Kita duwe peralatan produksi majeng sing njamin produk kita entuk sing paling apik ing saben tautan produksi.

Perusahaan kita duwe akeh persediaan titanium fasteners, sing bisa nyukupi pesenan global sing sithik lan para pelanggan sing mbutuhake pangiriman sing penting.Ing wektu sing padha, kita uga nyedhiyakake produk non-standar miturut gambar sing diwenehake dening pelanggan.

Aplikasi

Petroleum, metalurgi, kimia, elektronik, farmasi, Teknik kelautan, suku cadang mobil, suku cadang sepeda motor, aksesoris yacht, pasokan kaslametan ruangan, barang olahraga lan lapangan liyane.

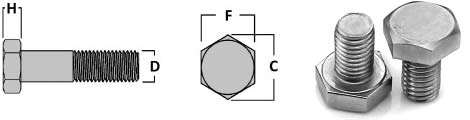

bolt titanium

| produk | Titanium lan Titanium alloy bolt |

| Ukuran | Diameter: M1.6-M30, Dawane: 10mm-300mm (0.39″-11.8″) |

| Bahan | Gr.1, Gr.2, Gr.5, Gr.7 etc |

| Standar | DIN912, DIN6912, DIN933, DIN931 lsp |

Kacang hex titanium

| produk | Titanium lan Titanium alloy nut |

| Ukuran | M8-M 80 x 6 |

| Bahan | Gr1, Gr2, Gr5, Gr7, Ti6Al4V ELI, lsp |

| Standar | DIN, ISO, JIS, dll. |

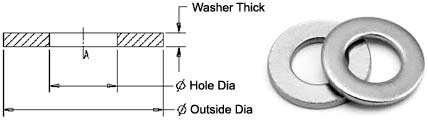

Tmesin cuci itanium

| produk | Titanium lan Titanium alloy washer |

| Ukuran | OD: 5mm-200mm (0.20″-7.87″), ID: 1mm-100mm (0.04″-3.94″), Ketebalan: 0.1mm-30mm (0.004″-1.18″) |

| Bahan | Gr.2, Gr.5 etc |

| Standar | DIN125 etc |

sekrup titanium

| produk | Titanium lan Titanium alloy screw |

| Ukuran | M1 nganti M42, Dawane: 10mm-300mm (0.39″-11.8″) |

| Bahan | Gr1, Gr.2, Gr.5, Gr.7, Gr.12 etc |

| Standar | DIN912, DIN933, DIN84, DIN85, DIN963, DIN7991, DIN6912, DIN931, ISO7380, lsp. |

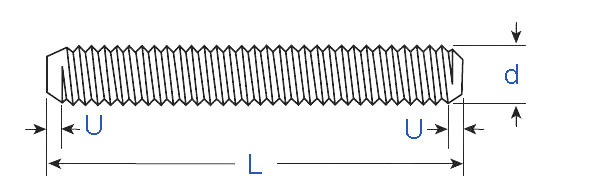

Kancing benang titanium

| produk | Titanium lan Titanium alloy Utas kandang jaran |

| Ukuran | Diameter: M1.6-M30, Dawane: 10mm-300mm (0.39″-11.8″) |

| Bahan | Gr.1, Gr.2, Gr.5, Gr.7, Gr.23 etc |

| Standar | DIN912, DIN933, DIN7991, DIN7984, DIN6921, ISO 7380, JIS, BS dll. |

Titanium Hex Bolts Dimensi

| Heavy Hex Bolt Diameter | D | F | C | H | |||||

| Dhiameter awak | Jembar Saben Flats | Jembar ing sudhut | dhuwur | ||||||

| Maks | dhasar | Maks | Min | Maks | Min | dhasar | Maks | Min | |

| 1/2 | 0.515 | 7/8 | 0,875 | 0.850 | 1.010 | 0.969 | 11/32 | 0.364 | 0.302 |

| 5/8 | 0.642 | 1-1/16 | 1.062 | 1.031 | 1.227 | 1.175 | 27/64 | 0.444 | 0.378 |

| 3/4 | 0.768 | 1-1/4 | 1.250 | 1.212 | 1.443 | 1.383 | 1/2 | 0.524 | 0.455 |

| 7/8 | 0.895 | 1-7/16 | 1.438 | 1.394 | 1.660 | 1.589 | 37/64 | 0.604 | 0.531 |

| 1 | 1.022 | 1-5/8 | 1.625 | 1.575 | 1.876 | 1.796 | 43/64 | 0.700 | 0.591 |

| 1-1/8 | 1.149 | 1-13/16 | 1.812 | 1.756 | 2.093 | 2.002 | 3/4 | 0.780 | 0.658 |

| 1-1/4 | 1.277 | 2 | 2.00 | 1.938 | 2.309 | 2.209 | 27/32 | 0.876 | 0.749 |

| 1-3/8 | 1.404 | 2-3/16 | 2.188 | 2.119 | 2.526 | 2.416 | 29/32 | 0.940 | 0.810 |

| 1-1/2 | 1.531 | 2-3/8 | 2.375 | 2.300 | 2.742 | 2.622 | 1 | 1.036 | 0.902 |

| 1-3/4 | 1.785 | 2-3/4 | 2.750 | 2.662 | 3.175 | 3.035 | 1-5/32 | 1.196 | 1.054 |

| 2 | 2.039 | 3-1/8 | 3.125 | 3.025 | 3.608 | 3.449 | 1-11/32 | 1.388 | 1.175 |

| 2-1/4 | 2.305 | 3-1/2 | 3.500 | 3.388 | 4.041 | 3.862 | 1-1/2 | 1.548 | 1.327 |

| 2-1/2 | 2.559 | 3-7/8 | 3.875 | 3.750 | 4.474 | 4.275 | 1-21/32 | 1.708 | 1.479 |

Ukuran Kacang Hex

| ISO Titanium Hex Nut NB | Nyabrang Corners | Ketebalan MAX | Ketebalan MIN | MAX Across Flats | MIN Across Flats |

| M 8 | 14.38 | 6.8 | 6.44 | 13 | 12.73 |

| M 10 | 17.77 | 8.4 | 8.04 | 16 | 15.73 |

| M 12 | 20.03 | 10.8 | 10.37 | 18 | 17.73 |

| M 14 | 23.35 | 12.8 | 12.1 | 21 | 20.67 |

| M 16 | 26.75 | 14.8 | 14.1 | 24 | 23.67 |

| M 18 | 29.56 | 15.8 | 15.1 | 27 | 26.16 |

| M 20 | 32.95 | 18 | 16.9 | 30 | 29.16 |

| M 22 | 37.29 | 19.4 | 18.1 | 34 | 33 |

| M 24 | 39.55 | 21.5 | 20.2 | 36 | 35 |

| M 27 | 45.2 | 23.8 | 22.5 | 41 | 40 |

| M 30 | 50.85 | 26.6 | 24.3 | 46 | 45 |

| M 33 | 55.37 | 28.7 | 27.4 | 50 | 49 |

| M 36 | 60.79 | 31 | 29.4 | 55 | 53.8 |

| M 39 | 66.44 | 33.4 | 31.8 | 60 | 58.8 |

| M 42 | 71.3 | 34 | 32.4 | 65 | 63.1 |

| M 45 | 76.95 | 36 | 34.4 | 70 | 68.1 |

| M 48 | 82.6 | 38 | 39.4 | 75 | 73.1 |

| M 52 | 88.25 | 42 | 40.4 | 80 | 78.1 |

| M 56 | 93.56 | 45 | 43.4 | 85 | 82.8 |

| M 60 | 99.21 | 48 | 46.4 | 90 | 87.8 |

| M 64 | 104.86 | 51 | 49.1 | 95 | 92.8 |

| M 68 | 110.51 | 54 | 52.1 | 100 | 97.8 |

| M 72x6 | 116.16 | 58 | 56.1 | 105 | 102.8 |

| M 76x6 | 121.81 | 61 | 59.1 | 110 | 107.8 |

| M 80x6 | 127.46 | 64 | 62.1 | 115 | 112.8 |

Titanium Flat Washer Dimensi

| Ti Alloy Bolt Ukuran | USS | SAE | ||||

| OD (ing.) | ID (ing.) | kekandelan | OD (ing.) | ID (ing.) | kekandelan | |

| 1/8 (#6) | - | - | - | 0.375 | 0.156 | .036/.065 |

| 5/32 (#8) | - | - | - | 0.438 | 0.188 | .036/.065 |

| 3/16 (#10) | 0.560 | 0.250 | .036/.065 | 0.500 | 0.220 | .036/.065 |

| 7/32 (#12) | - | - | - | 0.562 | 0.250 | .051/.080 |

| 1/4 (#14) | 0.734 | 0.312 | .051/.080 | 0.625 | 0.281 | .051/.080 |

| 5/16 | 0,875 | 0.375 | .064/.104 | 0.688 | 0.344 | .051/.080 |

| 3/8 | 1.000 | 0.438 | .064/.104 | 0.812 | 0.406 | .051/.080 |

| 7/16 | 1.250 | 0.500 | .064/.104 | 0.922 | 0.469 | .051/.080 |

| 1/2 | 1.375 | 0.562 | .086/.132 | 1.062 | 0.531 | .074/.121 |

| 9/16 | 1.469 | 0.625 | .086/.132 | 1.156 | 0.594 | .074/.121 |

| 5/8 | 1.750 | 0.688 | .108/.160 | 1.312 | 0.656 | .074/.121 |

| 3/4 | 2.000 | 0.812 | .122/.177 | 1.469 | 0.812 | .108/.160 |

| 7/8 | 2.250 | 0.938 | .136/.192 | 1.750 | 0.938 | .108/.160 |

| 1 | 2.500 | 1.062 | .136/.192 | 2.000 | 1.062 | .108/.160 |

| 1 1/8 | 2.750 | 1.250 | .136/.192 | 2.250 | 1.250 | .108/.160 |

| 1 1/4 | 3.000 | 1.375 | .136/.192 | 2.500 | 1.375 | .136/.192 |

| 1 3/8 | 3.250 | 1.500 | .153/.213 | 2.750 | 1.500 | .136/.213 |

| 1 1/2 | 3.500 | 1.625 | .153/.213 | 3.000 | 1.625 | .153/.213 |

| 1 5/8 | 3.750 | 1.750 | .153/.213 | - | - | - |

| 1 3/4 | 4.000 | 1.875 | .153/.213 | - | - | - |

| 1 7/8 | 4.250 | 2.000 | .153/.213 | - | - | - |

| 2 | 4.500 | 2.125 | .153/.213 | - | - | - |

| 2 1/4 | 4.750 | 2.375 | .193/.248 | - | - | - |

| 2 1/2 | 5.000 | 2.625 | .210/.280 | - | - | - |

| 2 3/4 | 5.250 | 2.875 | .228/.310 | - | - | - |

| 3 | 5.500 | 3.125 | .249/.327 | - | - | - |

Soket Kepala Cap Screw Dimensi

| Ti Alloy Screw Nom.Ukuran Thread Pitch | awak | sirah | sirah | Chamfer | Hexagon | Spline | kunci | Transisi | |||

| Maks | Min | Maks | Min | Maks | Min | Maks | Nom. | Nom. | Min | Maks | |

| M1,6 × 0,35 | 1.60 | 1.46 | 3.00 | 2.87 | 1.60 | 1.52 | 0.16 | 1.5 | 1.829 | 0.80 | 2.0 |

| M2 × 0.4 | 2.00 | 1.86 | 3.80 | 3.65 | 2.00 | 1.91 | 0.20 | 1.5 | 1.829 | 1.00 | 2.6 |

| M2.5 × 0.45 | 2.50 | 2.36 | 4.50 | 4.33 | 2.50 | 2.40 | 0.25 | 2.0 | 2.438 | 1.25 | 3.1 |

| M3 × 0,5 | 3.00 | 2.86 | 5.50 | 5.32 | 3.00 | 2.89 | 0.30 | 2.5 | 2.819 | 1.50 | 3.6 |

| M4 × 0.7 | 4.00 | 3.82 | 7.00 | 6.80 | 4.00 | 3.88 | 0.40 | 3.0 | 3.378 | 2.00 | 4.7 |

| M5 × 0.8 | 5.00 | 4.82 | 8.50 | 8.27 | 5.00 | 4.86 | 0.50 | 4.0 | 4.648 | 2.50 | 5.7 |

| M6 × 1 | 6.00 | 5.82 | 10.00 | 9.74 | 6.00 | 5.85 | 0.60 | 5.0 | 5.486 | 3.00 | 6.8 |

| M8 × 1.25 | 8.00 | 7.78 | 13.00 | 12.70 | 8.00 | 7.83 | 0.80 | 6.0 | 7.391 | 4.00 | 9.2 |

| M10 × 1.5 | 10.00 | 9.78 | 16.00 | 15.67 | 10.00 | 9.81 | 1.00 | 8.0 | … | 5.00 | 11.2 |

| M12 × 1,75 | 12.00 | 11.73 | 18.00 | 17.63 | 12.00 | 11.79 | 1.20 | 10.0 | … | 6.00 | 14.2 |

| M14 × 2b | 14.00 | 13.73 | 21.00 | 20.60 | 14.00 | 13.77 | 1.40 | 12.0 | … | 7.00 | 16.2 |

| M16 × 2 | 16.00 | 15.73 | 24.00 | 23.58 | 16.00 | 15.76 | 1.60 | 14.0 | … | 8.00 | 18.2 |

| M20 × 2.5 | 20.00 | 19.67 | 30.00 | 29.53 | 20.00 | 19.73 | 2.00 | 17.0 | … | 10.00 | 22.4 |

| M24 × 3 | 24.00 | 23.67 | 36.00 | 35.48 | 24.00 | 23.70 | 2.40 | 19.0 | … | 12.00 | 26.4 |

| M30 × 3.5 | 30.00 | 29.67 | 45.00 | 44.42 | 30.00 | 29.67 | 3.00 | 22.0 | … | 15.00 | 33.4 |

| M36 × 4 | 36.00 | 35.61 | 54.00 | 53.37 | 36.00 | 35.64 | 3.60 | 27.0 | … | 18.00 | 39.4 |

| M42 × 4.5 | 42.00 | 41.61 | 63.00 | 62.31 | 42.00 | 41.61 | 4.20 | 32.0 | … | 21.00 | 45.6 |

| M48 × 5 | 48.00 | 47.61 | 72.00 | 71.27 | 48.00 | 47.58 | 4.80 | 36.0 | … | 24.00 | |

Kancing benang titanium

| ANSI / ASMEB 18.31.2 Utas Rods-Unit: inci | ||||

| d | pitch | |||

| UNC | UNF | 8 UN | ||

| 1/4 | 0.25 | 20 | 28 | / |

| 5/16 | 0.3125 | 18 | 24 | / |

| 3/8 | 0.375 | 18 | 24 | / |

| 7/16 | 0.4375 | 14 | 20 | / |

| 1/2 | 0.5 | 13 | 20 | / |

| 9/16 | 0,5625 | 12 | 18 | / |

| 5/8 | 0.625 | 11 | 18 | / |

| 3/4 | 0.75 | 10 | 16 | / |

| 7/8 | 0,875 | 9 | 14 | / |

| 1 | 1 | 8 | 12 | 8 |

| 1-1/8 | 1.125 | 7 | 12 | 8 |

| 1-1/4 | 1.25 | 7 | 12 | 8 |

| 1-3/8 | 1.375 | 6 | 12 | 8 |

| Unit: inch | ||||

| d | pitch | |||

| UNC | UNF | 8 UN | ||

| 1-1/2 | 1.5 | 6 | 12 | 8 |

| 1-5/8 | 1.625 | / | / | 8 |

| 1-3/7 | 1.75 | 5 | / | 8 |

| 1-7/8 | 1.875 | / | / | 8 |

| 2 | 2 | 4-1/2 | / | 8 |

| 2-1/4 | 2.25 | 4-1/2 | / | 8 |

| 2-1/2 | 2.5 | 4 | / | 8 |

| 2-3/4 | 2.75 | 4 | / | 8 |

| 3 | 3 | 4 | / | 8 |

| 3-1/4 | 3.25 | 4 | / | 8 |

| 3-1/2 | 3.5 | 4 | / | 8 |

| 3-3/4 | 3.75 | 4 | / | 8 |

| 4 | 4 | 4 | / | 8 |

| L | 1/2<L≤2-1/2 | 2-1/2<L≤4 | 4<L≤8 | 8<L≤16 | 16 <L |

| Fastened toleransi dawa kandang jaran | ± 0,04 | ± 0,08 | ± 0,10 | ± 0,12 | ± 0,18 |

| Standar | Katrangan | Standar | Katrangan |

| DIN 84 | ngawut-awut sirah keju Slotted | DIN 439 | Kacang senggol |

| DIN 125 | Washer datar | DIN 963 | Slotted countersunk ngawut-awut warata sirah |

| DIN 127 | Spring lock washers | DIN 965 | Phillips ngawut-awut mesin sirah flat |

| DIN 912 | Sekrup tutup kepala soket hex | DIN 985 | Kacang kunci (karo sisipan non-logam) |

| DIN913/DIN914/DIN915/DIN916 | Setel sekrup | DIN 1665/DIN 6921 | Hex bolt karo flange |

| DIN 931 | Sekrup tutup kepala hex (bagian benang) | DIN 6912/DIN 7984 | Hexagon soket ngawut-awut tutup sirah lancip |

| DIN 933 | Sekrup tutup kepala hex (benang lengkap) | DIN 7991 | Flat kepala countersunk ngawut-awut tutup soket |

| DIN 934 | Kacang hex | DIN 9021 | Mesin cuci datar |

Bahan Setara Bahan Kanggo Pengikat Titanium

| STANDAR | WERKSTOFF NR. | UNS |

| Titanium Grade 2 | 3.7035 | R50400 |

| Titanium Grade 5 | 3.7165 | R56400 |

Karakteristik Mekanik Pengikat Titanium

| sasmita | Kekuwatan Tarik (min) | Kekuwatan Ngasilake 0,2% Offset | Elongation ing 2 inci utawa 50mm% (min) | ||

| KSI | MPa | KSI | MPa | ||

| Gr.1 | 35 | 240 | 20 – 45 | 138 – 310 | 24 |

| Gr.2 | 50 | 345 | 40 – 65 | 275 – 450 | 20 |

| Gr.3 | 65 | 450 | 55 – 80 | 380 – 550 | 18 |

| Gr.4 | 80 | 550 | ≥70 | ≥483 | 15 |

| Gr.5 | 138 | 950 | ≥128 | ≥880 | 14 |

| Gr.7 | 50 | 345 | ≥40 | ≥275 | 24 |

| Gr.9 | 125 | 860 | ≥105 | ≥725 | 10 |

| Gr.12 | 70 | 483 | ≥50 | ≥345 | 18 |

| Gr.23 | 125 | 860 | ≥115 | ≥790 | 15 |

| unsur | Kapadhetan | Titik Lebur | Kekuwatan Tensile | Kekuwatan Ngasilake (0,2% Offset) | Elongation |

| Titanium Gr.2 | 4,5 g/cm3 | 1665 °C (3030 °F) | Psi – 49900, MPa – 344 | Psi – 39900, MPa – 275 | 20 % |

| Titanium Gr.5 | 4,43 g/cm3 | 1632 °C (2970 °F) | Psi – 138000, MPa – 950 | Psi – 128000, MPa – 880 | 14 % |

Komposisi Bahan Kimia Pengikat Titanium

| sasmita | Fe% | C% | N% | H% | O% | Al% | V% | Mo% | Ni% | Pd% | Ti |

| Gr1 | 0.2 | 0.08 | 0.03 | 0.015 | 0.18 | — | — | — | — | — | BAL. |

| Gr2 | 0.3 | 0.08 | 0.03 | 0.015 | 0.25 | — | — | — | — | — | BAL. |

| Gr3 | 0.3 | 0.08 | 0.05 | 0.015 | 0.35 | — | — | — | — | — | BAL. |

| Gr4 | 0.3 | 0.08 | 0.05 | 0.015 | 0.40 | — | — | — | — | — | BAL |

| Gr5 | 0.25 | 0.08 | 0.03 | 0.015 | 0.02 | 5.5 – 6.75 | 3.5 – 4.5 | — | — | — | BAL |

| Gr7 | 0.3 | 0.08 | 0.03 | 0.015 | 0.25 | — | — | — | — | 0.12 – 0.25 | BAL. |

| Gr9 | 0.25 | 0.08 | 0.03 | 0.015 | 0.15 | 2.5 – 3.3 | 2.0 – 3.0 | — | — | — | BAL. |

| Gr12 | 0.3 | 0.08 | 0.03 | 0.015 | 0.25 | — | — | 0.2 – 0.4 | 0.6 – 0.9 | — | BAL. |

| Gr23 | 0.3 | 0.08 | 0.03 | 0.015 | 0.13 | 5.5 – 6.75 | — | — | — | — | B |