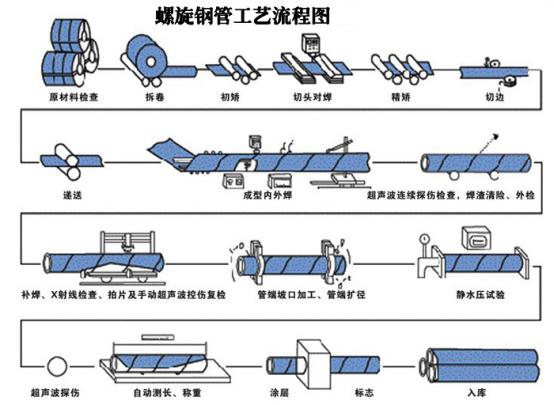

Umbhobho wentsimbi ye-Spiralyicoil engumtya njengento ekrwada, ehlala ishushu extrusion ukubumba, oluzenzekelayo kabini ngocingo-macala ephantsi arc inkqubo welding edityanisiweyo spiral umthungo umbhobho yentsimbi iinkqubo eziphambili zemveliso zezi zilandelayo:

Inkqubo yokuvelisa umbhobho wensimbi ojikelezayo

1. I-probe yebhodi evulekileyo: Emva kokungena kumgca wokuvelisa ipleyiti evulekileyo, ibhodi yokuqala yokuvavanya i-ultrasonic.

2. Leveling Milling: Umatshini tyaba intsimbi anvil ukwenzela ukuba curl yoqobo, kwaye ke ngokusebenzisa umatshini yokusila emphethweni macala amabini yokusila intsimbi, ukuze kuhlangatyezwane neemfuno ipleyiti ububanzi, ipleyiti edge parallelism kunye imilo groove.

3. Ukucheba ukubumba: umgca wokuvelisa ipleyiti yentsimbi ecaleni komphandle we-curl ejikelezayo ibe ityhubhu.

4. Ukusikwa kweempundu: ukuwelda kwe-arc kumacala amabini aphantsi kwamanzi usebenzisa iteknoloji ephezulu ukuya kwi-welding yangaphambili, i-welding yangaphakathi, i-welding yangaphandle. Unyawo lwe-Ion olusikwe kubude obuchaziweyo obudityanisiweyo bokusetyenziswa kombhobho ojikelezayo njalo njalo.

5. ukuhlolwa okubonakalayo: ngabasebenzi abaqeqeshiweyo kunye nobugcisa kwezinye iiparamitha ezisisiseko eziza kujongwa.

6. Ukufumanisa i-ultrasonic flaw: i-weld yangaphakathi nangaphandle kunye ne-weld kumacala omabini ezinto ezisisiseko 100% yokuhlola.

7. X-ray ukubona: welds yangaphakathi nangaphandle 100% X-reyi yoshishino TV khangela inkqubo yokwenziwa komfanekiso ukuqinisekisa ukuba ukusetyenziswa kokubona ubuntununtunu.

8. Uvavanyo loxinzelelo: i-spiral steel pipe hydrostatic test machine-by-root test ukuqinisekisa ukuba umbhobho wokuvavanya uxinzelelo uhlangabezana nemigangatho efunekayo.

9. chamfering intloko ethe tyaba: spiral steel umbhobho yokuhlolwa olwenziwa emva processing isiphelo umbhobho, ukuhlangabezana neemfuno umbhobho isiphelo beveling ubukhulu.

10. Ukuhlolwa kokugqibela: ukufunyanwa kwe-ultrasonic kunye ne-X-ray kwakhona kunye nombhobho wensimbi ojikelezayo ugqiba ukuhlolwa kwe-particle magnetic, khangela ukuba kukho iingxaki kunye ne-welding pipe iphelisa iziphene.

11. Ukumakishwa kwe-oyile: umbhobho wensimbi ojikelezayo emva kokudlula u-oyile ukuthintela ukubola, kwaye ngokweemfuno zomsebenzisi zokumakisha.

Ixesha lokuposa: Jun-22-2022