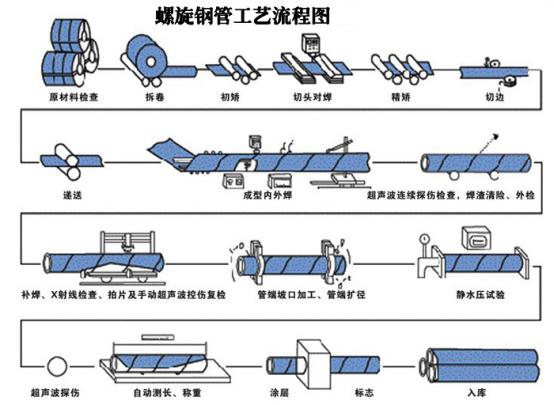

Spiral steel pipe is a strip coil as raw material, often warm extrusion molding, automatic double wire-sided submerged arc welding process welded spiral seam steel pipe main production processes are as follows:

Production process of spiral steel pipe

1. unwinding board probe: After entering the unwinding plate production line, the first full-board ultrasonic testing.

2. Leveling Milling: The flat steel anvil machine so that the original curl, and then through the edge milling machine for two-sided steel milling, so as to meet the requirements of the plate width, plate edge parallelism and groove shape.

3. shear molding: the steel plate production line along the outer edge of the spiral curl into a tube.

4. butt cut: double-sided submerged arc welding using advanced technology to pre-welding, internal welding, outside welding. Ion foot cut to specification length welded spiral pipe use and so on.

5. visual inspection: by professional and technical personnel to some of the basic parameters to be checked.

6. The ultrasonic flaw detection: internal and external weld and weld on both sides of the base material 100% inspection.

7. X-ray detection: internal and external welds 100% X-ray industrial TV check image processing system to ensure that the use of detection sensitivity.

8. The pressure test: the spiral steel pipe hydrostatic testing machine-by-root test to ensure that the pressure test pipe meet the required standards.

9. chamfering flat head: spiral steel pipe inspection carried out after the pipe end processing, to meet the requirements of the pipe end beveling size

10. Final inspection: ultrasonic and X-ray detection again and spiral steel pipe ends magnetic particle inspection, check if there are problems and welding pipe ends defects.

11. oiled marking: spiral steel pipe after passing were oiled to prevent corrosion, and according to user requirements for marking.

Post time: Jun-22-2022